Nissan Murano Z50 (2005 year). Manual - part 89

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER

EC-179

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2005 August

2005 Murano

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Diagnostic Procedure

ABS004C0

1.

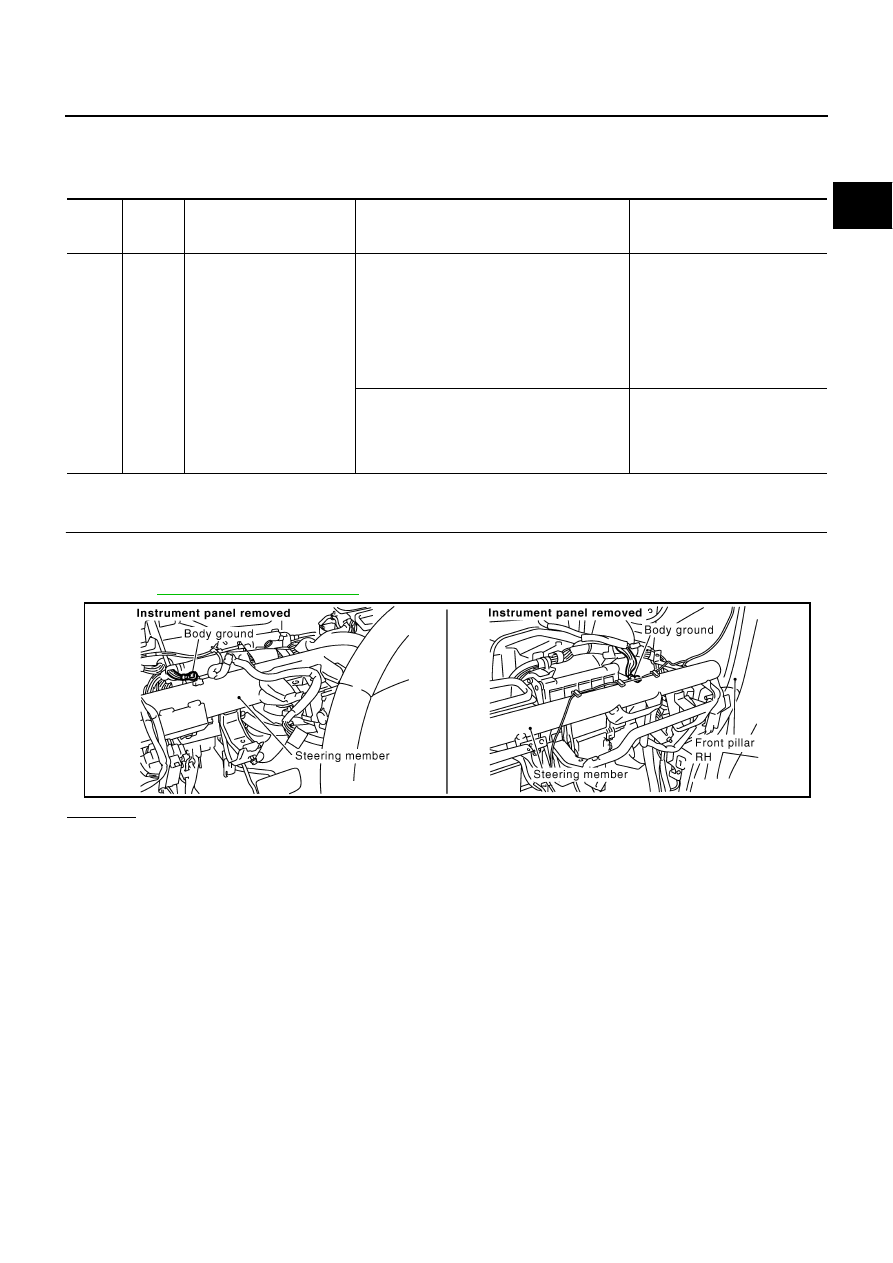

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Loosen and retighten two ground screws on the body.

Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

6

L/R

Heated oxygen sensor 2

heater (bank 2)

[Engine is running]

●

Engine speed is below 3,600 rpm after the

following conditions are met.

–

Engine: after warming up

–

Keeping the engine speed between 3,500

and 4,000 rpm for 1 minute and at idle for 1

minute under no load.

0 - 1.0V

[Ignition switch: ON]

●

Engine stopped

[Engine is running]

●

Engine speed is above 3,600 rpm.

BATTERY VOLTAGE

(11 - 14V)

PBIB1835E