Nissan Murano Z50 (2004 year). Manual - part 220

TRANSFER ASSEMBLY

TF-63

C

E

F

G

H

I

J

K

L

M

A

B

TF

Revision: 2004 November

2004 Murano

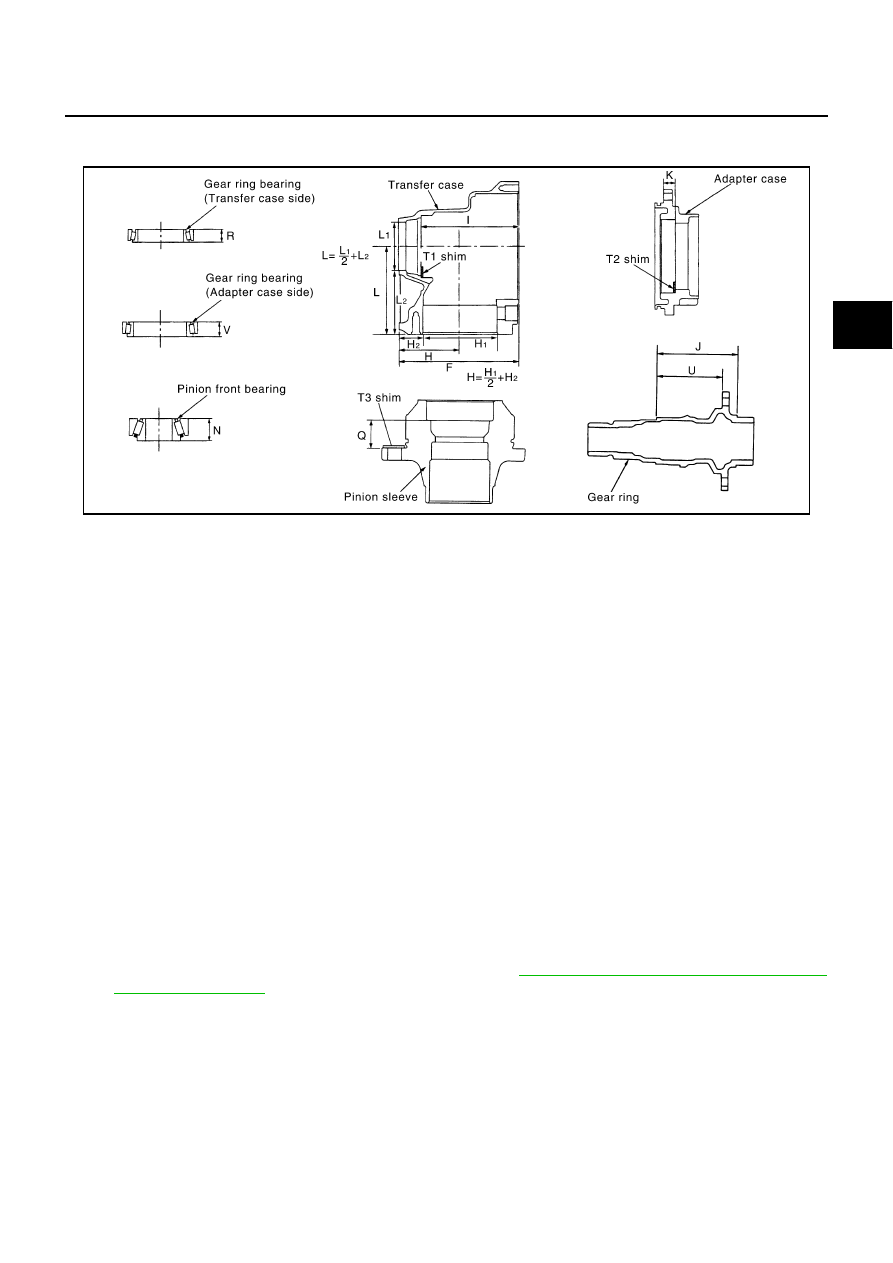

SELECTING ADJUSTING SHIMS

Measurement points

Gear Ring Bearing Adjusting Shim (Transfer Case Side)

1.

Measure the points F, H, I, R and U shown in the measurement points.

2.

Convert the values F, H, I, R and U according to the standards below.

3.

Check dimension Z on the drive gear side face.

NOTE:

Dimension Z indicates the difference between the optimum engagement and the standard dimensions in

increments of 0.01mm (0.0004 in) written on the drive gear side face.

4.

Use the formula below to calculate gear ring bearing adjusting shim (transfer case side) thickness T

1

.

5.

Select the gear ring bearing adjusting shim (transfer case side).

●

For information on selecting an adjusting shim, refer to

TF-70, "Gear Ring Bearing Adjusting Shim

CAUTION:

●

Only one adjusting shim can be selected.

●

If no adjusting shim with the calculated value is available, select the thicker and closest one.

Gear Ring Bearing Adjusting Shim (Adapter Case Side)

1.

Measure the points F, H, J, K, U and V shown in the measurement points.

2.

Convert the values F, H, J, K, U and V according to the standards below.

SDIA1179E

F:

Value obtained by subtracting 163.00 mm (6.42 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

H:

Value obtained by subtracting 83.00 mm (3.27 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

I:

Value obtained by subtracting 131.90 mm (5.19 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

R:

Value obtained by subtracting 17.00 mm (0.67 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

U:

Value obtained by subtracting 89.50 mm (3.524 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

T

1

= (I - F + H + Z - U - R)

×

0.01 mm (0.0004 in) + 1.49 mm (0.0587 in)