Nissan Murano Z50 (2004 year). Manual - part 219

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-47

C

E

F

G

H

I

J

K

L

M

A

B

TF

Revision: 2004 November

2004 Murano

2.

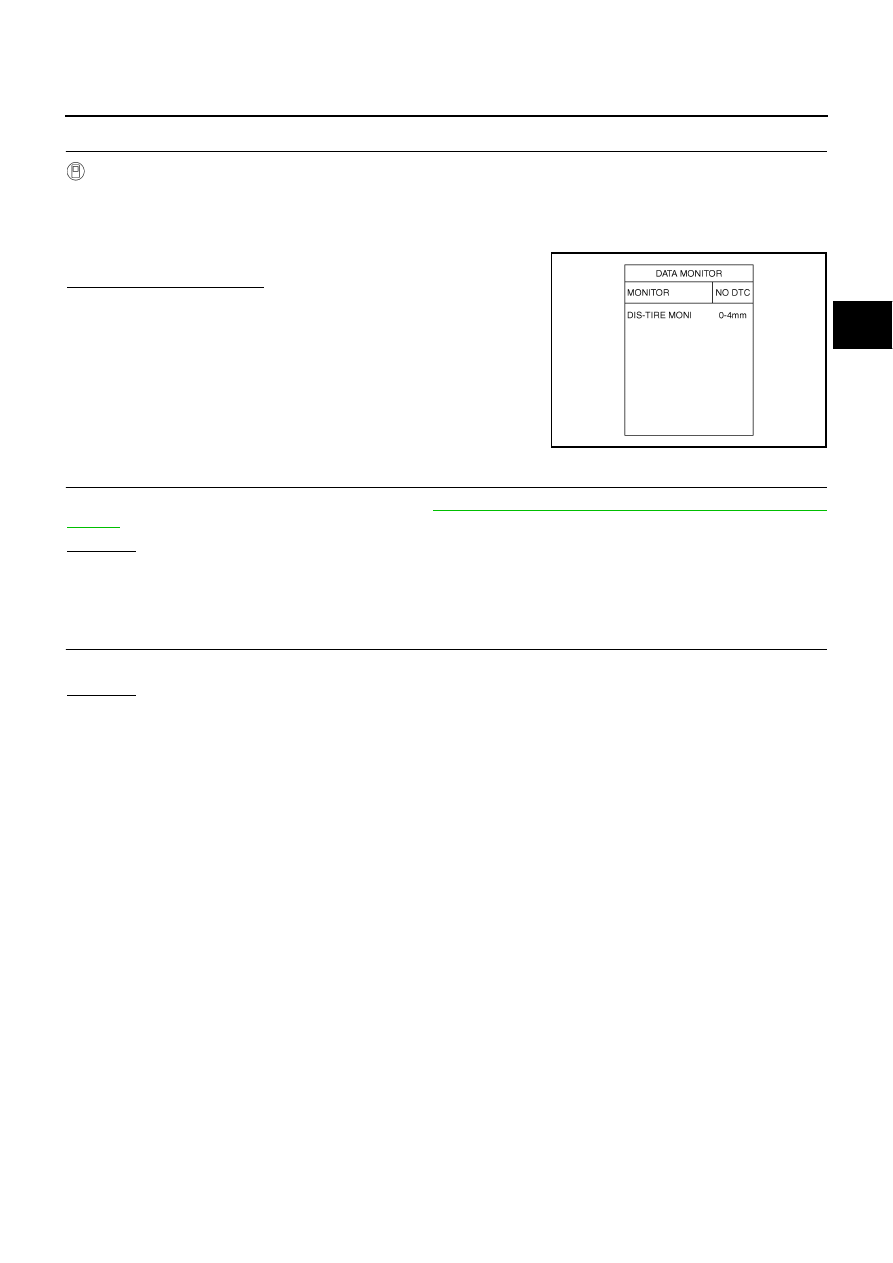

CHECK INPUT SIGNAL OF TIRE DIAMETER

With CONSULT-II

1.

Start engine.

2.

Drive at 20 km/h (12 MPH) or more for approx. 200 seconds.

3.

Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

4.

Check monitor “DIS-TIRE MONI”.

Display of “DIS-TIRE MONI”

“0-4mm”>>INSPECTION END

Except for “0-4mm”>>GO TO 3.

3.

CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to

TF-22, "AWD Control Unit Input/Output Signal Reference

OK or NG

OK

>> GO TO 4.

NG

>> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

4.

SYMPTOM CHECK

Check again.

OK or NG

OK

>> INSPECTION END

NG

>> Replace AWD control unit.

SDIA1900E