Nissan Murano Z50 (2004 year). Manual - part 216

COLLISION DIAGNOSIS

SRS-61

C

D

E

F

G

I

J

K

L

M

A

B

SRS

Revision: 2004 November

2004 Murano

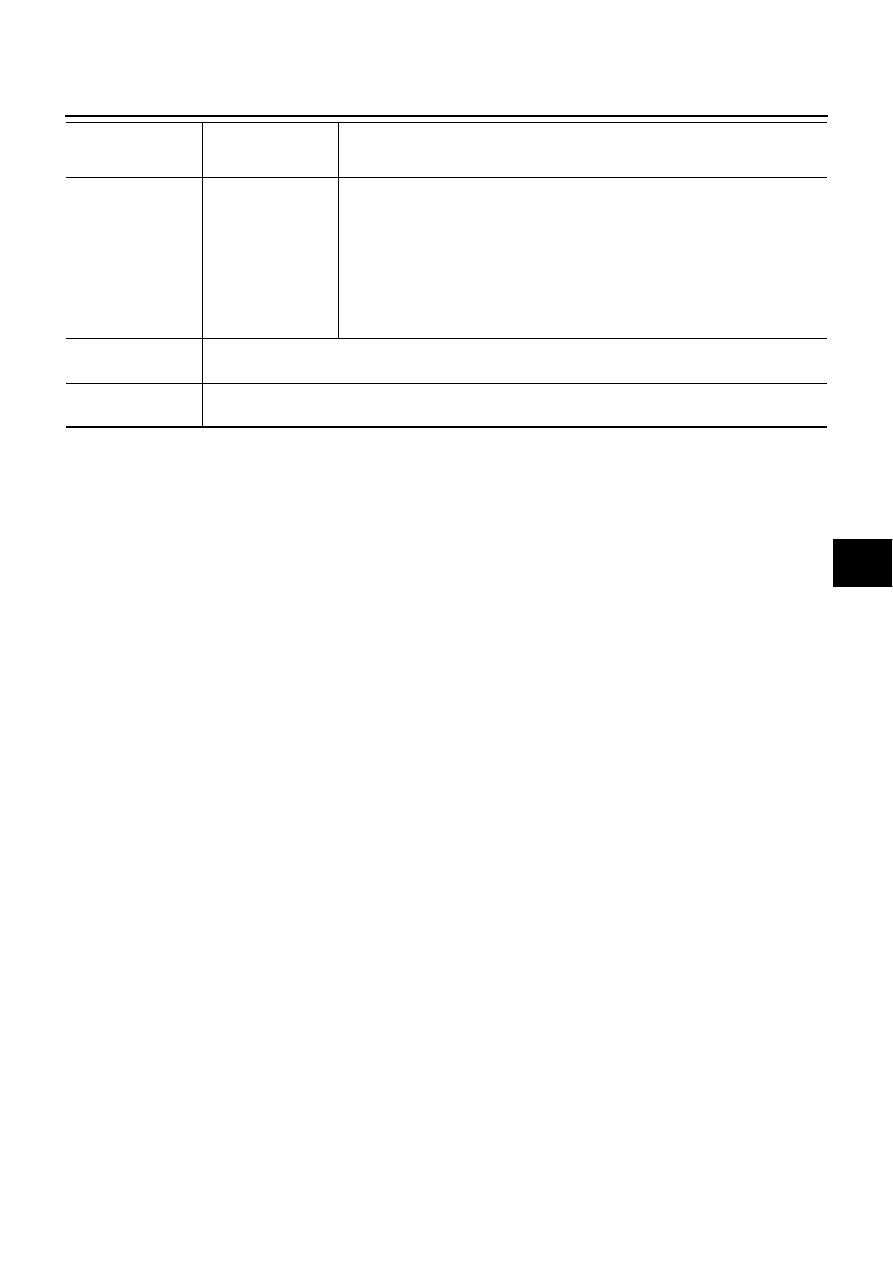

Seat with front side

air bag

REPLACE all parts of

front seatback

(including front seat-

back frame)

1. Visually check the seat on the collision side.

2. Remove the seat on the collision side and check the following for damage and

deformities.

–

Harness, connectors and terminals

–

Frame and recliner (for front and rear seat), and also adjuster and slides (for front

seat)

3. If no damage is found, reinstall the seat.

4. If damaged—REPLACE the damaged seat parts using new bolts.

Center inner pillar

1. Check the center inner pillar on the collision side for damage (dents, cracks, deformation).

2. If damaged—REPAIR the center inner pillar.

Trim/headlining

1. Check for visible signs of damage (dents, cracks, deformation) of the interior trim on the collision side.

2. If damaged—REPLACE the damaged trim parts.

Part

Front side air bag and

side curtain air bag is

activated

Front side air bag and side curtain air bag is NOT activated