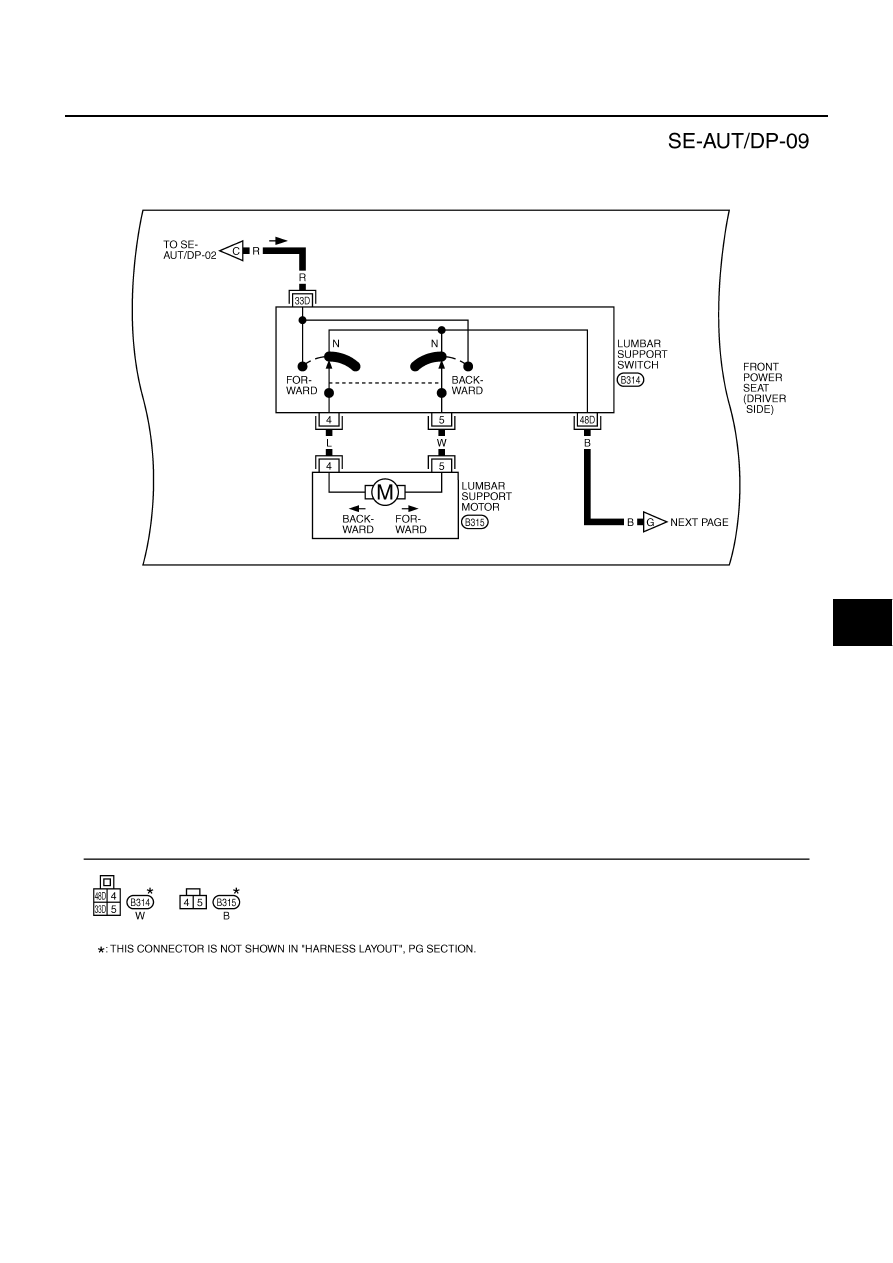

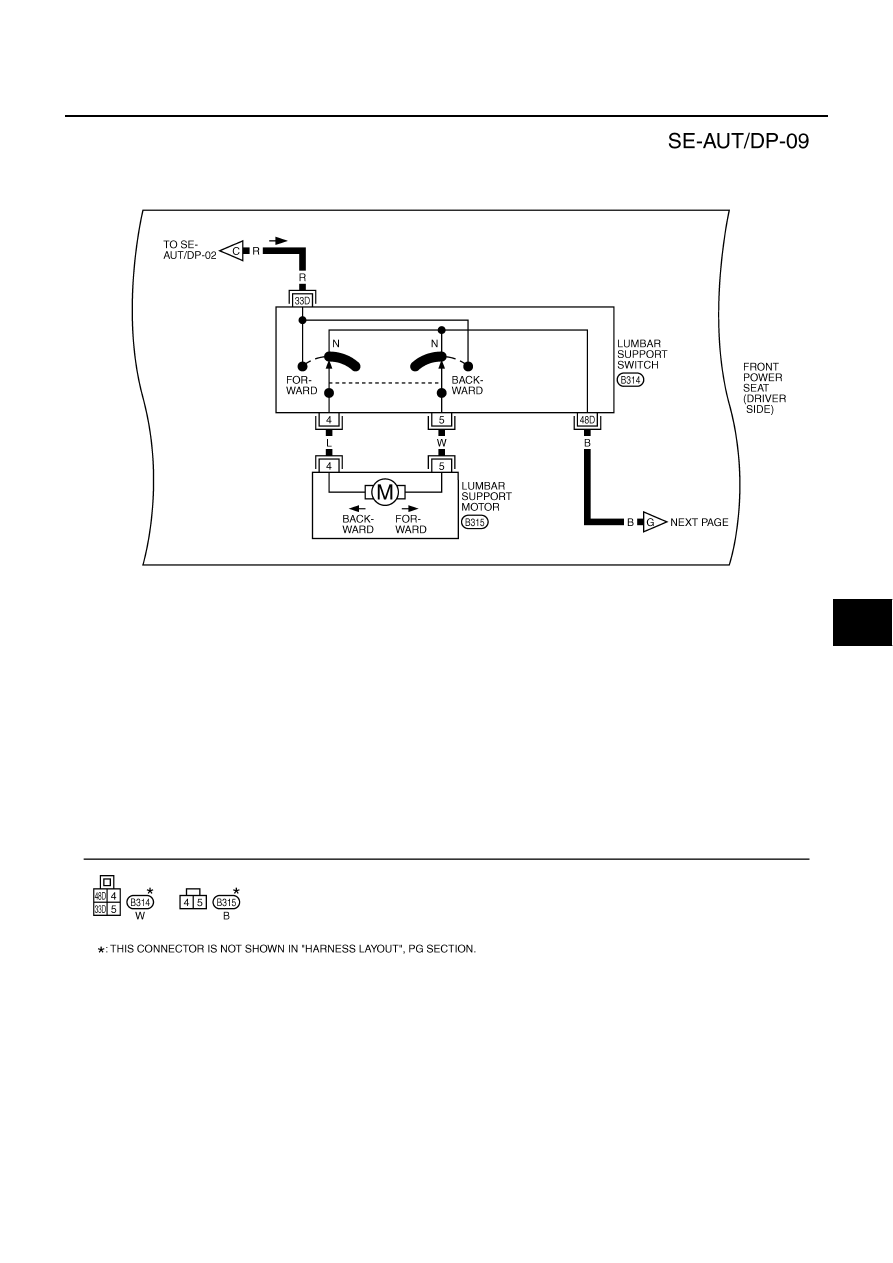

Nissan Murano Z50 (2004 year). Manual - part 207

AUTOMATIC DRIVE POSITIONER

SE-29

C

D

E

F

G

H

J

K

L

M

A

B

SE

Revision: 2004 November

2004 Murano

TIWA0525E

|

|

|

AUTOMATIC DRIVE POSITIONER SE-29 C D E F G H J K L M A B SE Revision: 2004 November 2004 Murano TIWA0525E |