Nissan Murano Z50 (2004 year). Manual - part 204

STARTING SYSTEM

SC-11

C

D

E

F

G

H

I

J

L

M

A

B

SC

Revision: 2004 November

2004 Murano

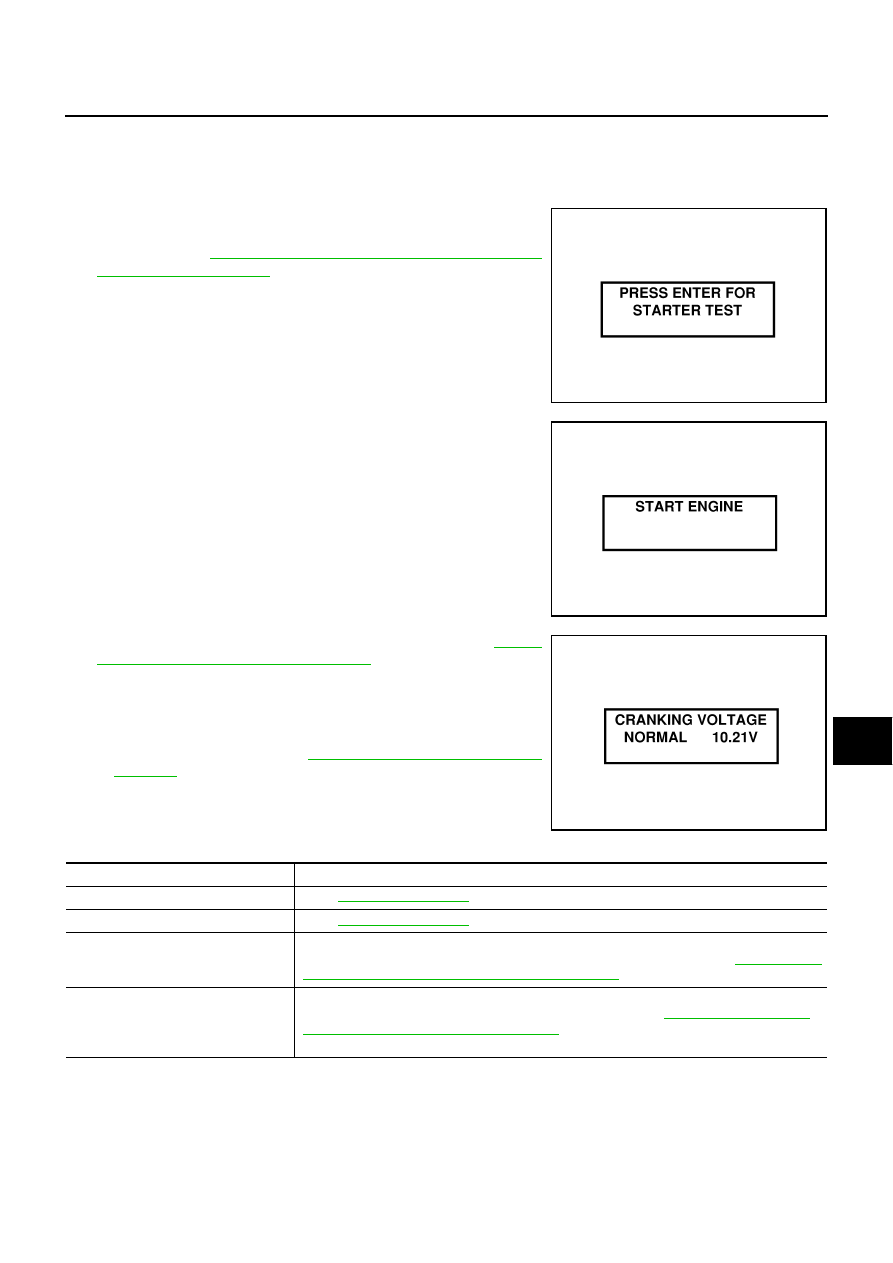

Trouble Diagnosis with Battery/Starting/Charging System Tester

AKS004F1

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be done

as a set from start to finish.

1.

Turn off all loads on the vehicle electrical system.

2.

Perform battery test with Battery/Starting/Charging system

tester. Refer to

SC-6, "Trouble Diagnosis with Battery/Starting/

.

3.

Press “ENTER” to begin the starting system test.

4.

Start the engine.

5.

Diagnosis result is displayed on the tester. Refer to

"DIAGNOSTIC RESULT ITEM CHART"

.

NOTE:

●

If the starter performs normally but the engine does not start,

perform engine diagnosis.

●

For intermittent “NO CRANK” or “NO STARTER OPERA-

TION” incidents, refer to

.

DIAGNOSTIC RESULT ITEM CHART

SEL408X

SEL409X

SEL410X

Diagnostic item

Service procedure

CRANKING VOLTAGE NORMAL

Go to

CRANKING VOLTAGE LOW

Go to

CHARGE BATTERY

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Per-

form battery test again with Battery/Starting/Charging system tester. Refer to

Diagnosis with Battery/Starting/Charging System Tester"

.

REPLACE BATTERY

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

test again with Battery/Starting/Charging system tester. Refer to

with Battery/Starting/Charging System Tester"

. If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.