Nissan Murano Z50 (2004 year). Manual - part 128

GI-38

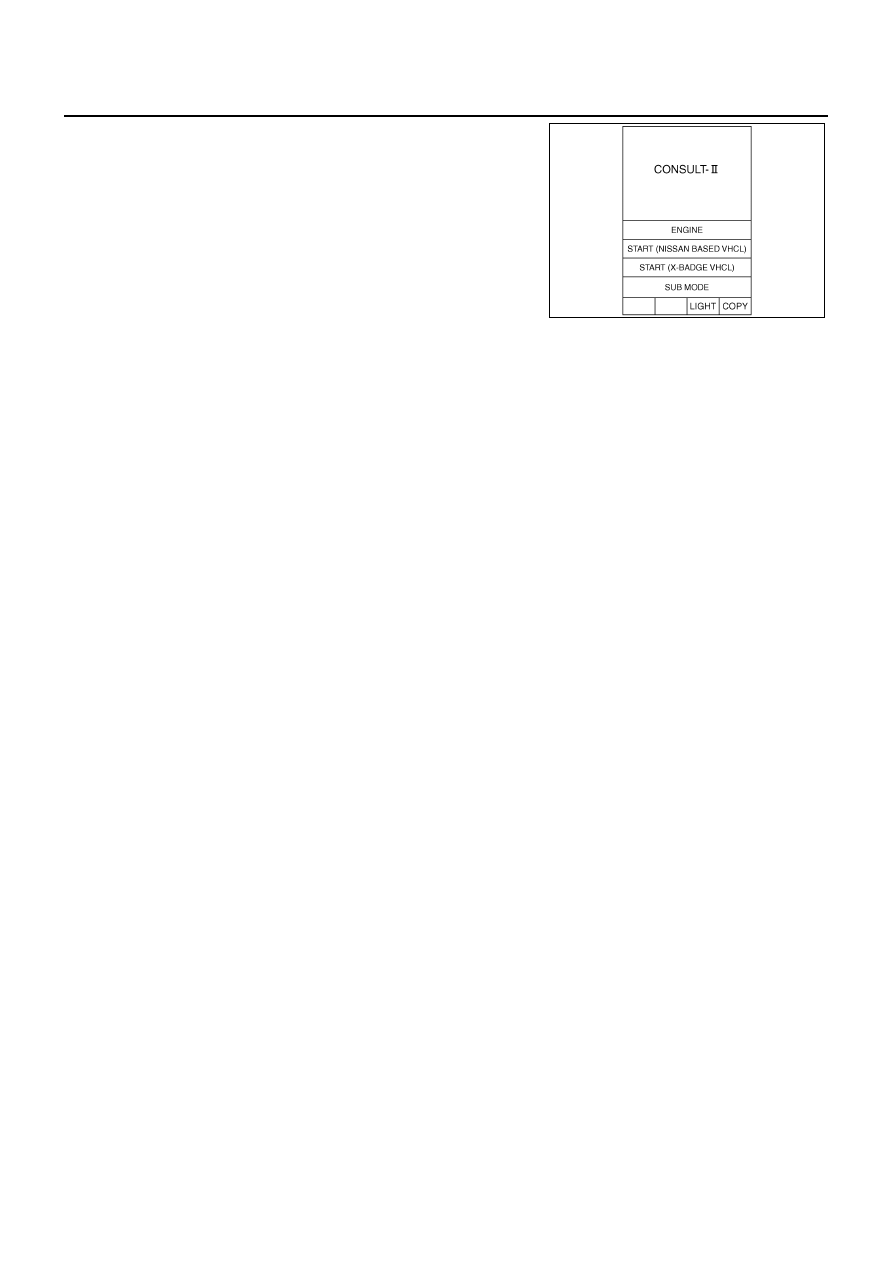

CONSULT-II CHECKING SYSTEM

Revision: 2004 November

2004 Murano

2.

If necessary, turn on the ignition switch.

3.

Touch "START(NISSAN BASED VHCL)" or System Shortcut key

(eg: ENGINE) on the screen.

SAIA0450E