Nissan Murano Z50 (2004 year). Manual - part 121

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-139

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision: 2004 November

2004 Murano

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

*

1

: Cam wear limit

*

2

: Total indicator reading

Valve Lifter

Unit: mm (in)

Valve Clearance

Unit: mm (in)

*: Approximately 80

°

C (176

°

F)

Items

Standard

Limit

Camshaft journal oil clearance

No. 1

0.045 - 0.086 (0.0018 - 0.0034)

0.15 (0.0059)

No. 2, 3, 4

0.035 - 0.076 (0.0014 - 0.0030)

Camshaft bracket inner diameter

No. 1

26.000 - 26.021 (1.0236 - 1.0244)

—

No. 2, 3, 4

23.500 - 23.521 (0.9252 - 0.9260)

—

Camshaft journal diameter

No. 1

25.935 - 25.955 (1.0211 - 1.0218)

—

No. 2, 3, 4

23.445 - 23.465 (0.9230 - 0.9238)

—

Camshaft end play

0.115 - 0.188 (0.0045 - 0.0074)

0.24 (0.0094)

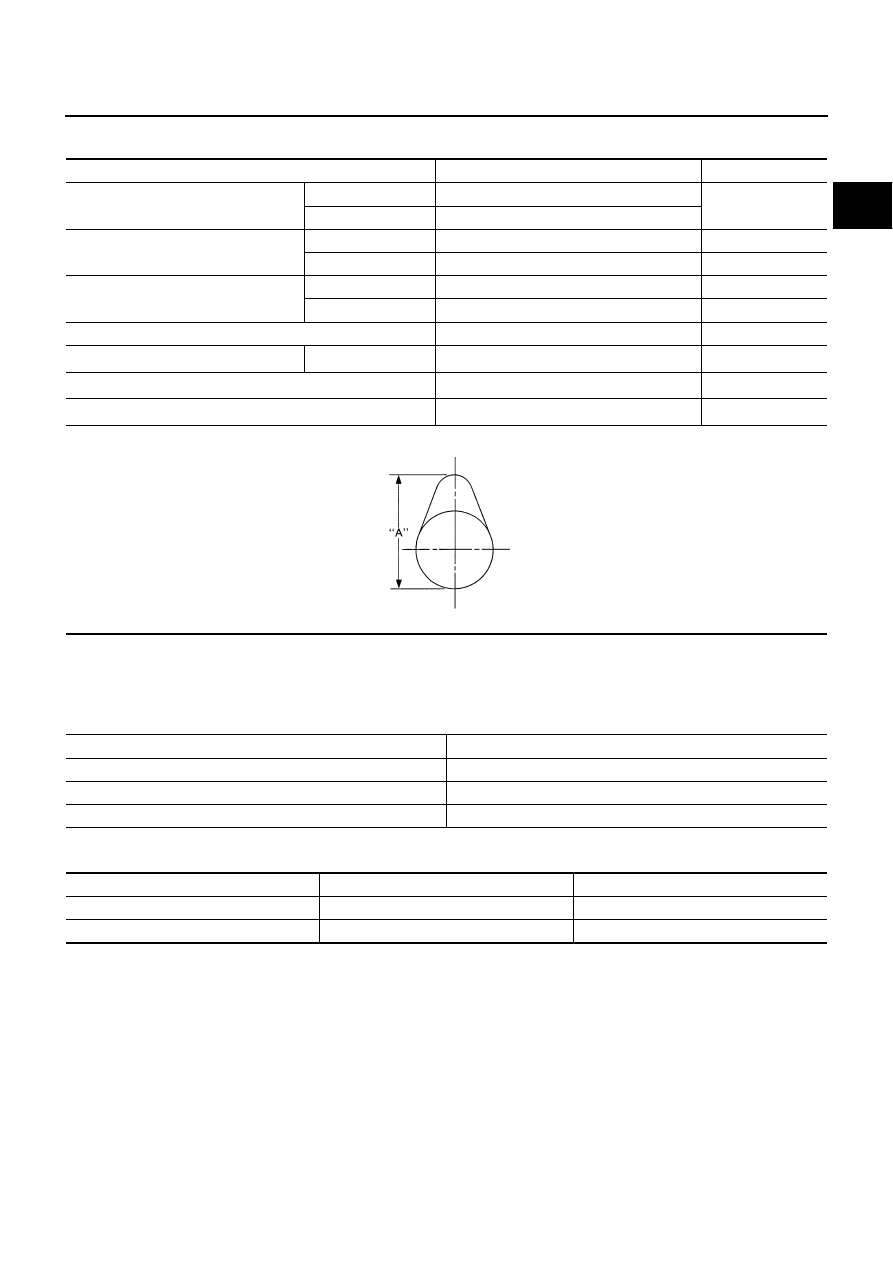

Camshaft cam height “A”

Intake and exhaust

44.865 - 45.055 (1.7663 - 1.7738)

0.2 (0.008)*

1

Camshaft runout [TIR*

2

]

Less than 0.02 mm (0.001)

0.05 (0.002)

Camshaft sprocket runout [TIR*

2

]

—

0.15 (0.0059)

SEM671

Items

Standard

Valve lifter outer diameter

33.977 - 33.987 (1.3377 - 1.3381)

Valve lifter hole diameter

34.000 - 34.016 (1.3386 - 1.3392)

Valve lifter clearance

0.013 - 0.039 (0.0005 - 0.0015)

Items

Cold

Hot* (reference data)

Intake

0.26 - 0.34 (0.010 - 0.013)

0.304 - 0.416 (0.012 - 0.016)

Exhaust

0.29 - 0.37 (0.011 - 0.015)

0.308 - 0.432 (0.012 - 0.017)