Nissan Murano Z50 (2004 year). Manual - part 77

DTC P0011, P0021 IVT CONTROL

EC-143

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2004 November

2004 Murano

DTC P0011, P0021 IVT CONTROL

PFP:23796

Description

ABS004BI

SYSTEM DESCRIPTION

*: This signal is sent to the ECM through CAN Communication line

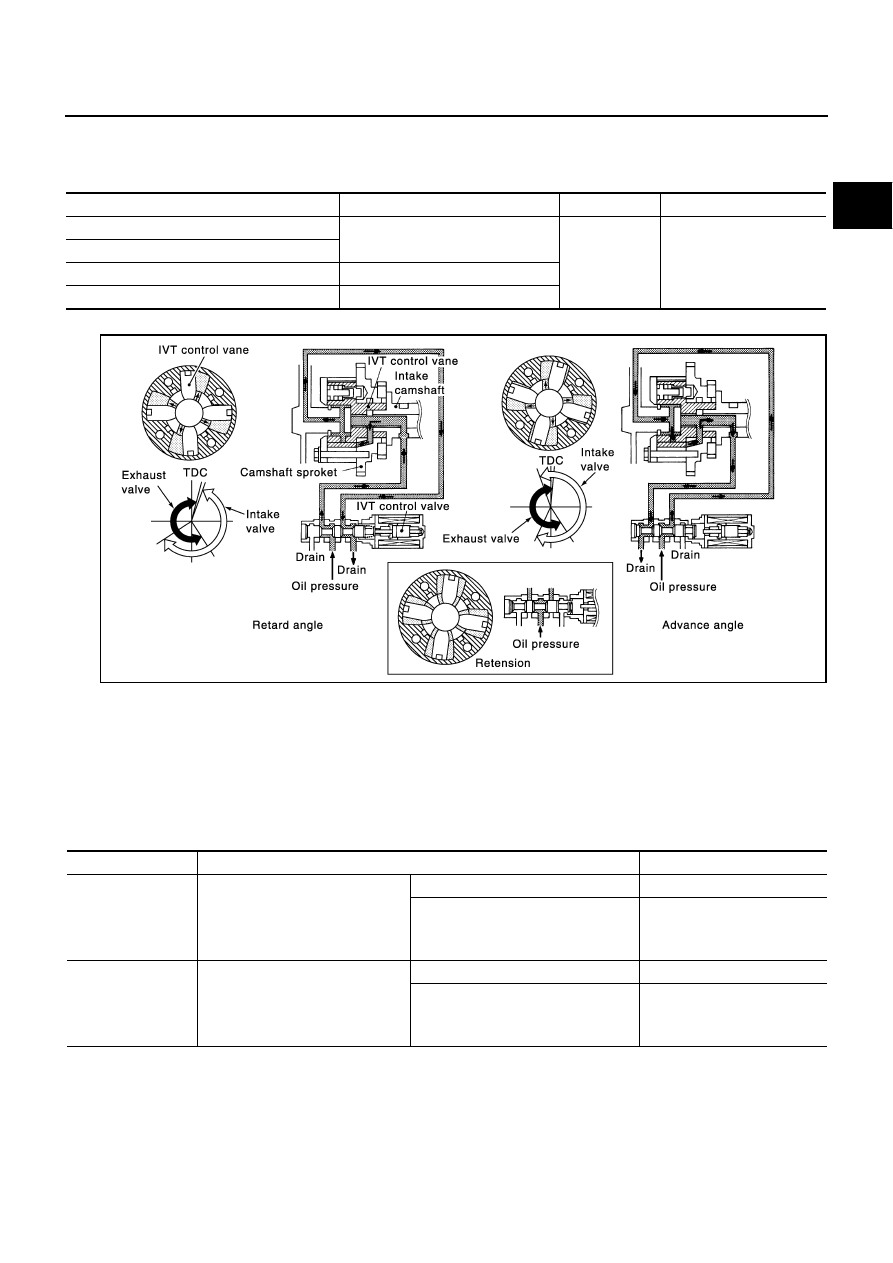

This mechanism hydraulically controls cam phases continuously with the fixed operating angle of the intake

valve.

The ECM receives signals such as crankshaft position, camshaft position, engine speed, and engine coolant

temperature. Then, the ECM sends ON/OFF pulse duty signals to the intake valve timing control solenoid

valve depending on driving status. This makes it possible to control the shut/open timing of the intake valve to

increase engine torque in low/mid speed range and output in high-speed range.

CONSULT-II Reference Value in Data Monitor Mode

ABS004BJ

Specification data are reference values.

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Engine speed and piston position

Intake valve

timing control

Intake valve timing control

solenoid valve

Camshaft position sensor (PHASE)

Engine coolant temperature sensor

Engine coolant temperature

Wheel sensor*

Vehicle speed

PBIB1389E

MONITOR ITEM

CONDITION

SPECIFICATION

INT/V TIM (B1)

INT/V TIM (B2)

●

Engine: After warming up

●

Shift lever: P or N

●

Air conditioner switch: OFF

●

No-load

Idle

−

5

°

- 5

°

CA

2,000 rpm

Approx. 0

°

- 30

°

CA

INT/V SOL (B1)

INT/V SOL (B2)

●

Engine: After warming up

●

Shift lever: P or N

●

Air conditioner switch: OFF

●

No-load

Idle

0% - 2%

2,000 rpm

Approx. 0% - 50%