Nissan Murano Z50 (2004 year). Manual - part 76

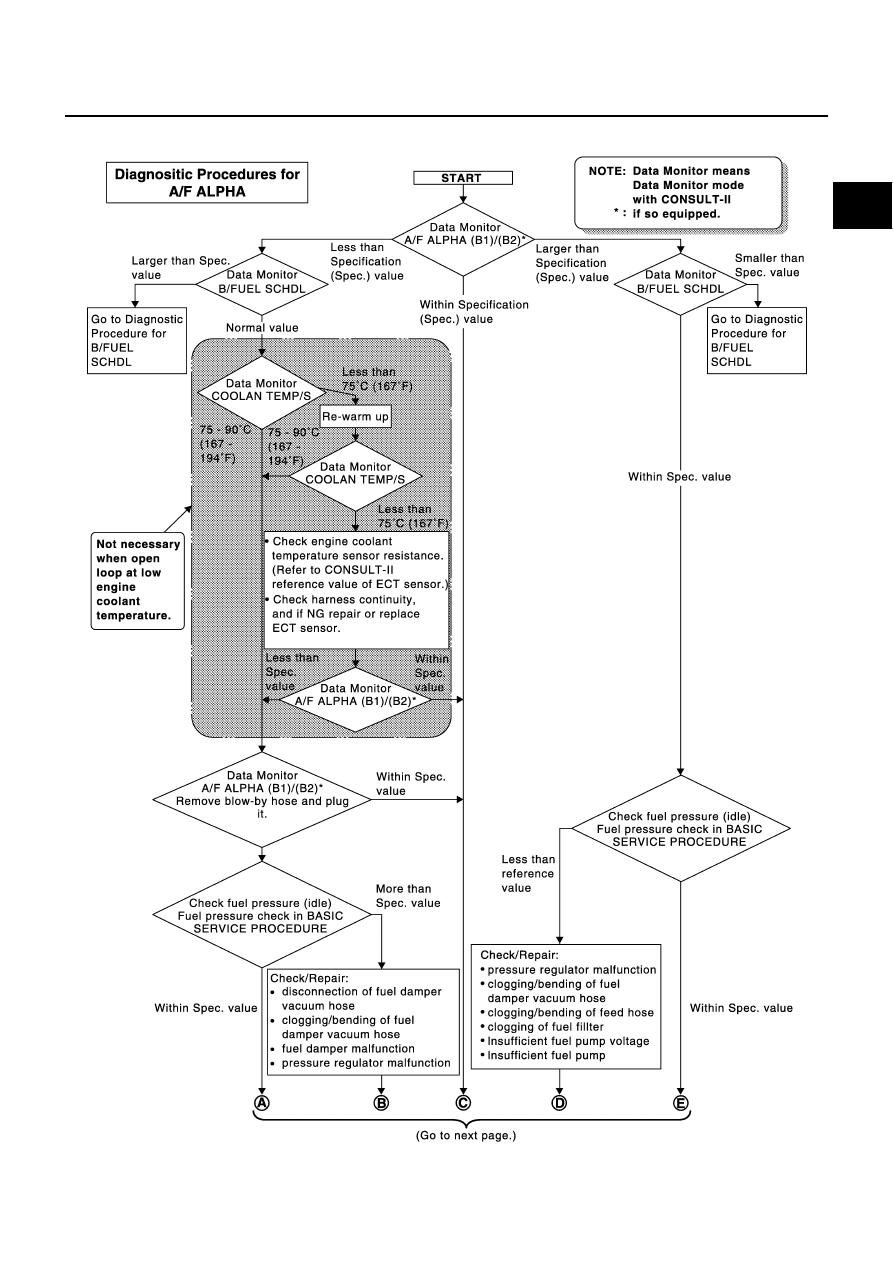

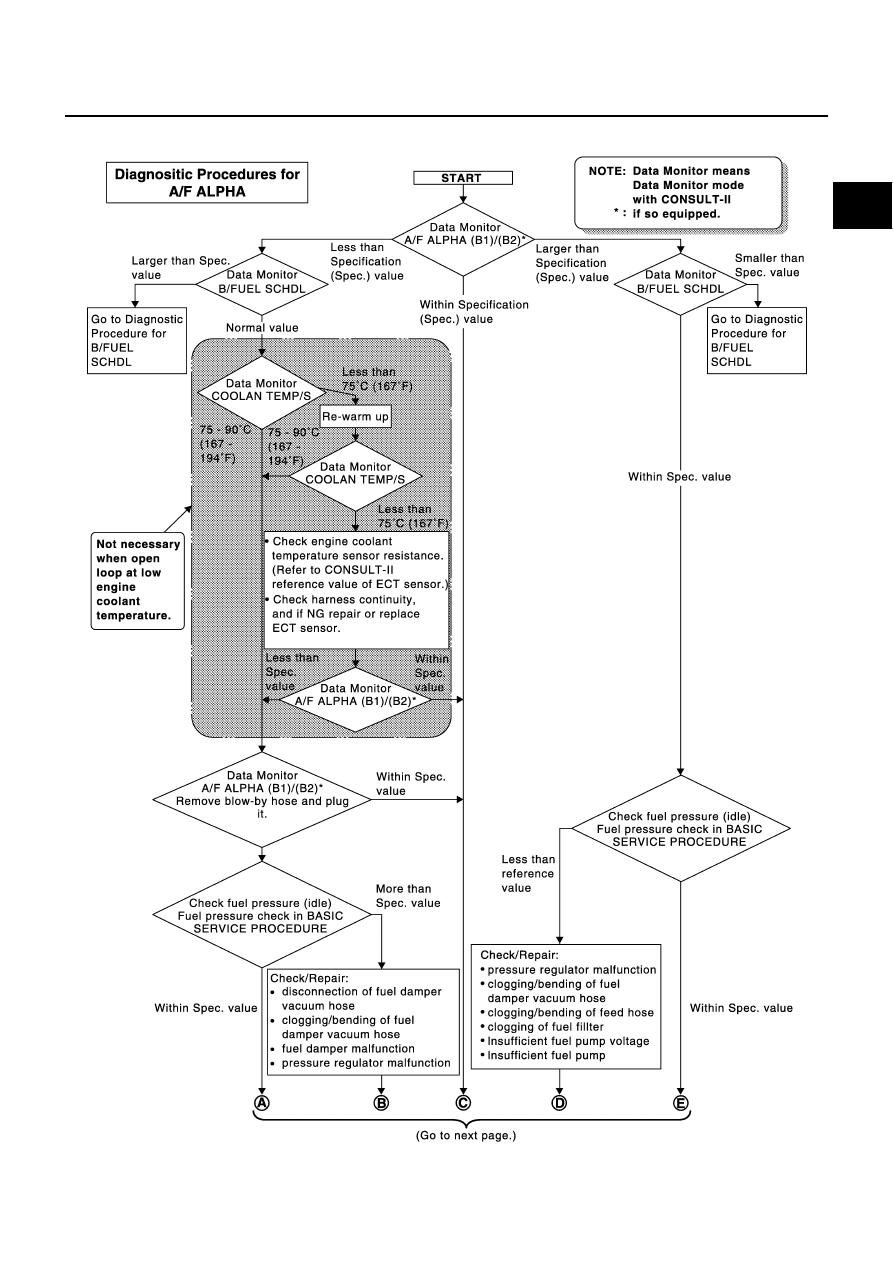

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-127

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2004 November

2004 Murano

Diagnostic Procedure

ABS004B8

SEF613ZD

|

|

|

TROUBLE DIAGNOSIS - SPECIFICATION VALUE EC-127 C D E F G H I J K L M A EC Revision: 2004 November 2004 Murano Diagnostic Procedure ABS004B8 SEF613ZD |