Nissan Murano Z50 (2004 year). Manual - part 70

BASIC SERVICE PROCEDURE

EC-31

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2004 November

2004 Murano

BASIC SERVICE PROCEDURE

PFP:00018

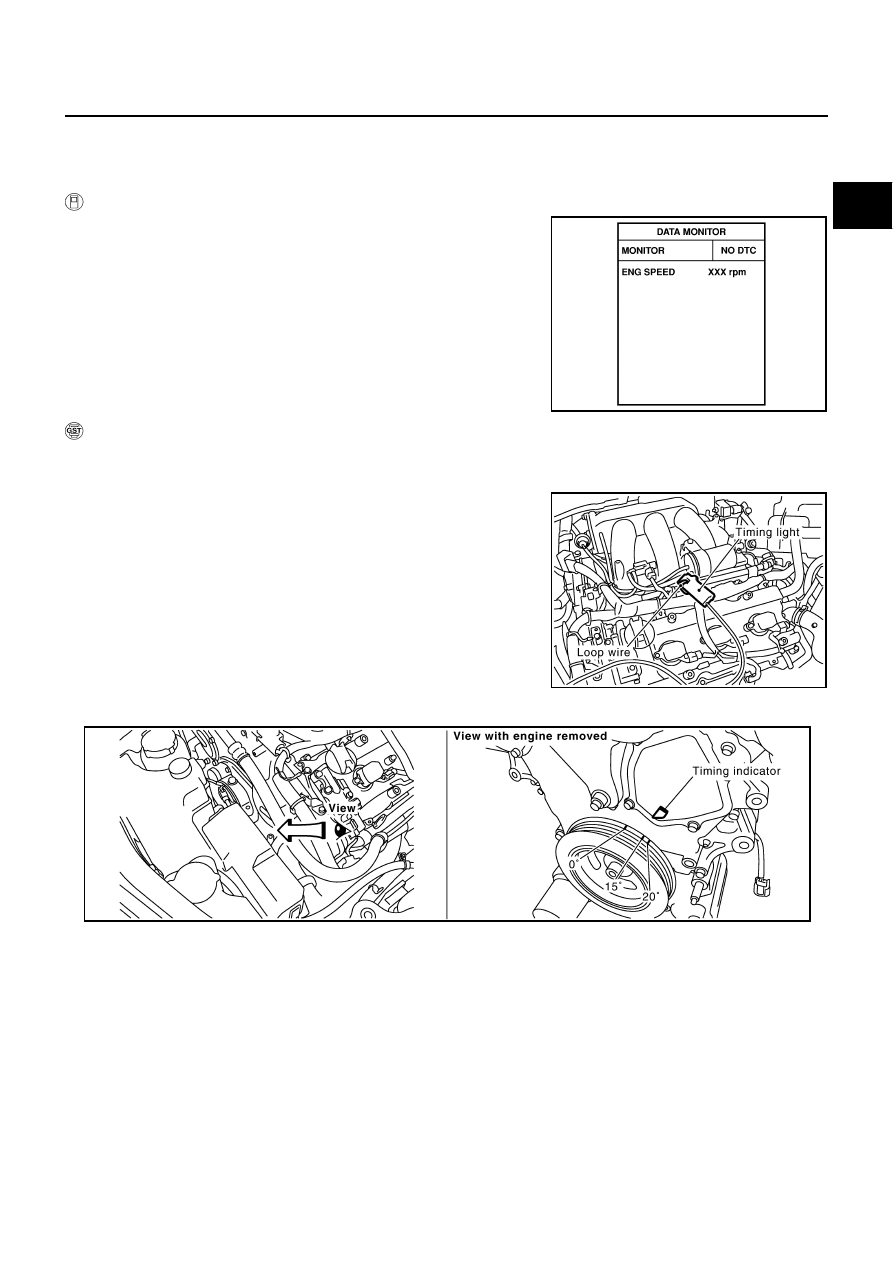

Idle Speed and Ignition Timing Check

ABS004AG

IDLE SPEED

With CONSULT-II

Check idle speed in “DATA MONITOR” mode with CONSULT-II.

With GST

Check idle speed with GST.

IGNITION TIMING

1.

Attach timing light to loop wire as shown.

2.

Check ignition timing.

SEF058Y

PBIB1374E

PBIB1382E