Nissan Murano Z50 (2004 year). Manual - part 48

RADIATOR (ALUMINUM TYPE)

CO-19

C

D

E

F

G

H

I

J

K

L

M

A

CO

Revision: 2004 November

2004 Murano

4.

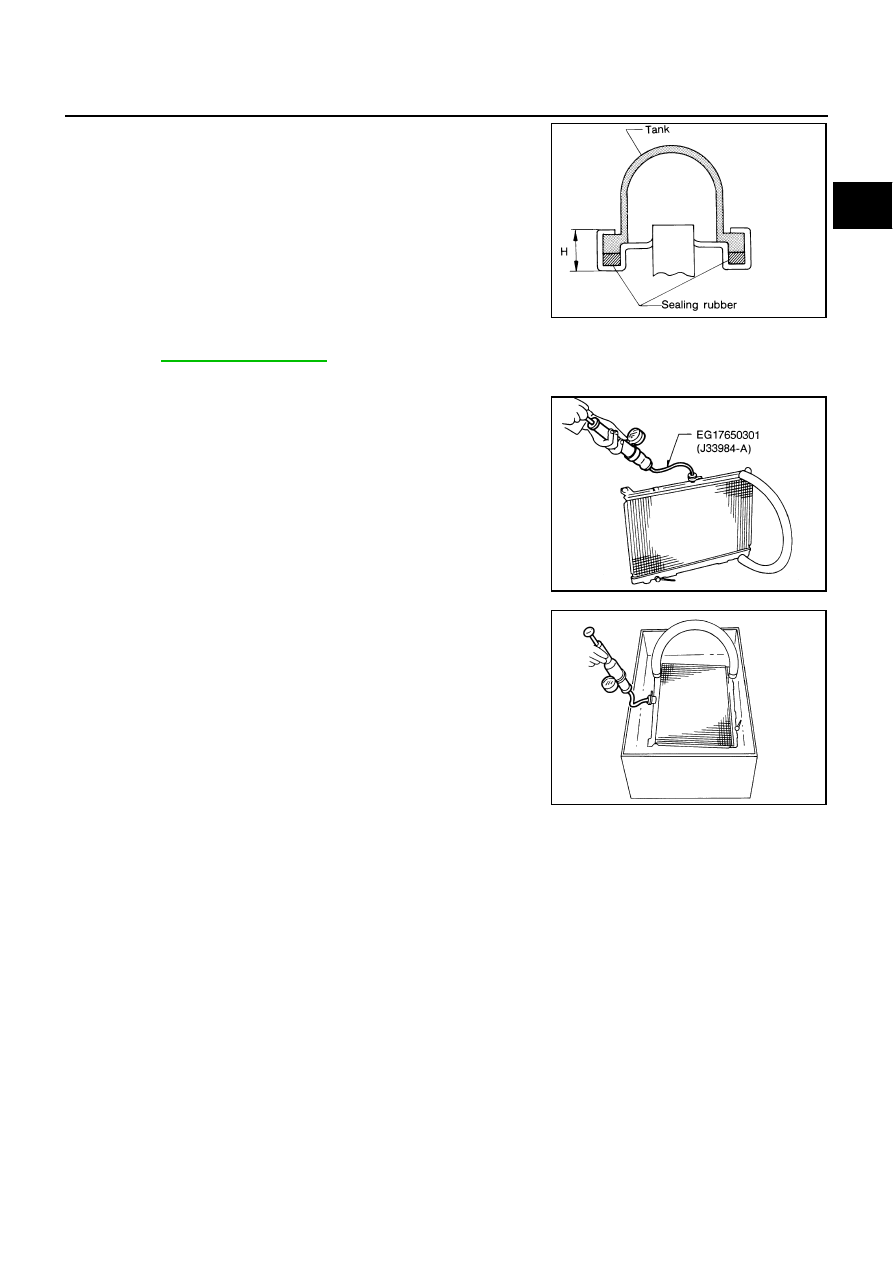

Make sure that the rim is completely crimped down.

5.

Make sure that there is no leakage.

Refer to

INSPECTION

1.

Apply pressure with radiator cap tester adapter [SST] and radia-

tor cap tester (commercial service tool).

WARNING:

To prevent the risk of hose coming undone while under

pressure, securely fasten it down with hose clamp.

CAUTION:

Attach hose to CVT fluid cooler to seal its inlet and outlet.

2.

Check for leakage by soaking radiator in water container with

the testing pressure applied.

Standard height “H”

: 8.0 - 8.4 mm (0.315 - 0.331 in)

SLC554A

Testing pressure

: 157 kPa (1.6 kg/cm

2

, 23 psi)

SLC933-A

SLC934