Nissan Murano Z50 (2003 year). Manual - part 286

WW-48

FRONT WIPER AND WASHER SYSTEM

Revision; 2004 April

2003 Murano

INSTALLATION

1.

Install wiper motor and linkage to the vehicle.

2.

Connect wiper motor assembly to the connector. Turn wiper switch ON to operate wiper motor, then turn

wiper switch OFF (auto stop).

3.

Attach washer tube to washer tube joint.

4.

Install cowl top cover. Refer to

5.

WW-47, "Removal and Installation of Front Wiper Arms, Adjustment of Wiper

CAUTION:

●

Do not drop the wiper motor or cause it to contact other parts.

●

Check grease conditions of the motor arm and wiper link joint (at retainer side). Apply grease if

necessary.

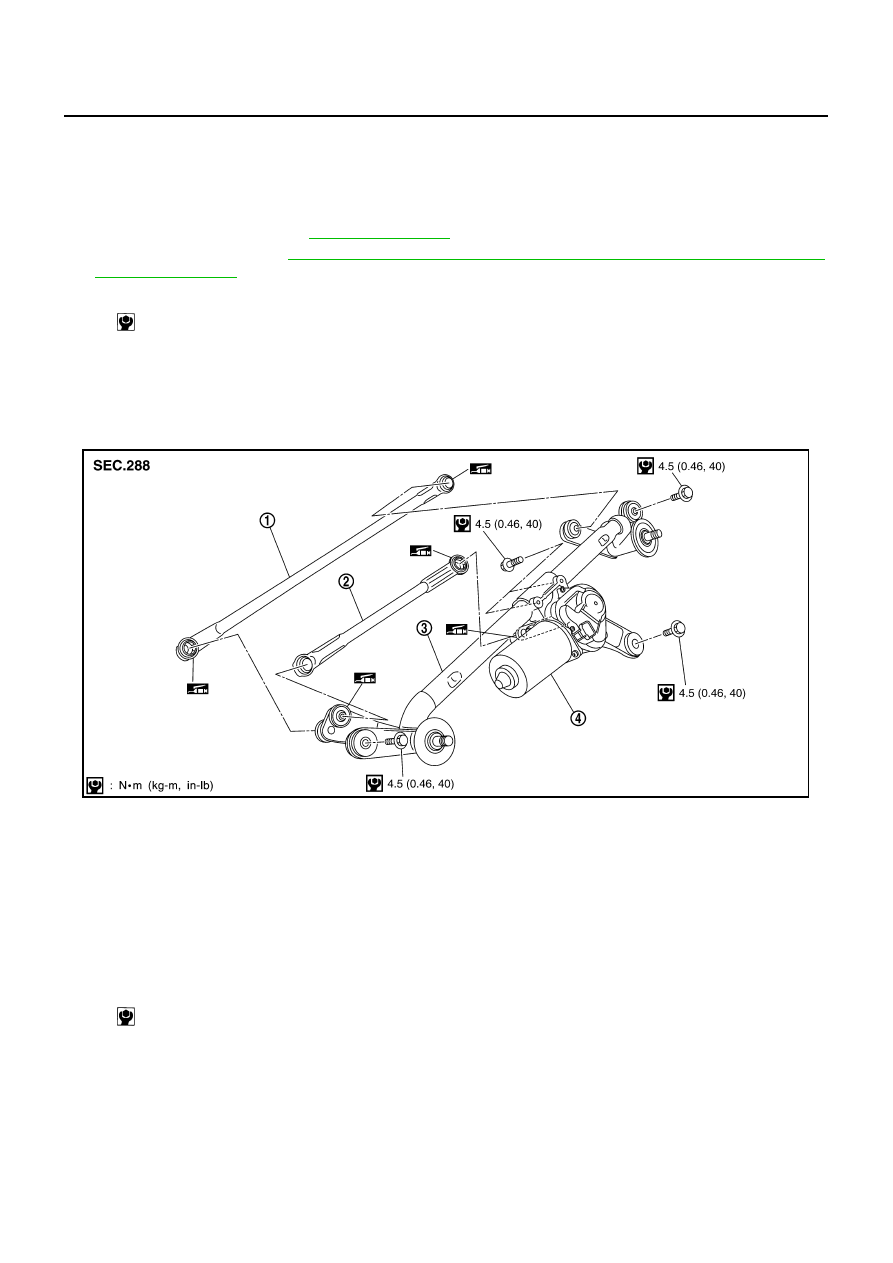

Disassembly and Assembly of Front Wiper Motor and Linkage

AKS005H8

DISASSEMBLY

1.

Remove wiper link from wiper frame and the motor arm.

2.

Remove wiper motor mounting bolts, and remove wiper motor from wiper frame.

ASSEMBLY

Paying attention to the work listed below, assemble in reverse order of disassembly.

Wiper motor and linkage mounting bolts

: 4.5 N·m (0.46 kg-m, 40 in-lb)

PKIA7852E

1.

Wiper link 1

2.

Wiper link 2

3.

Wiper frame

4.

Wiper motor

Wiper motor mounting bolts:

: 4.5 N·m (0.46 kg-m, 40 in-lb)