Nissan Murano Z50 (2003 year). Manual - part 269

SE-96

AUTOMATIC DRIVE POSITIONER

Revision; 2004 April

2003 Murano

3.

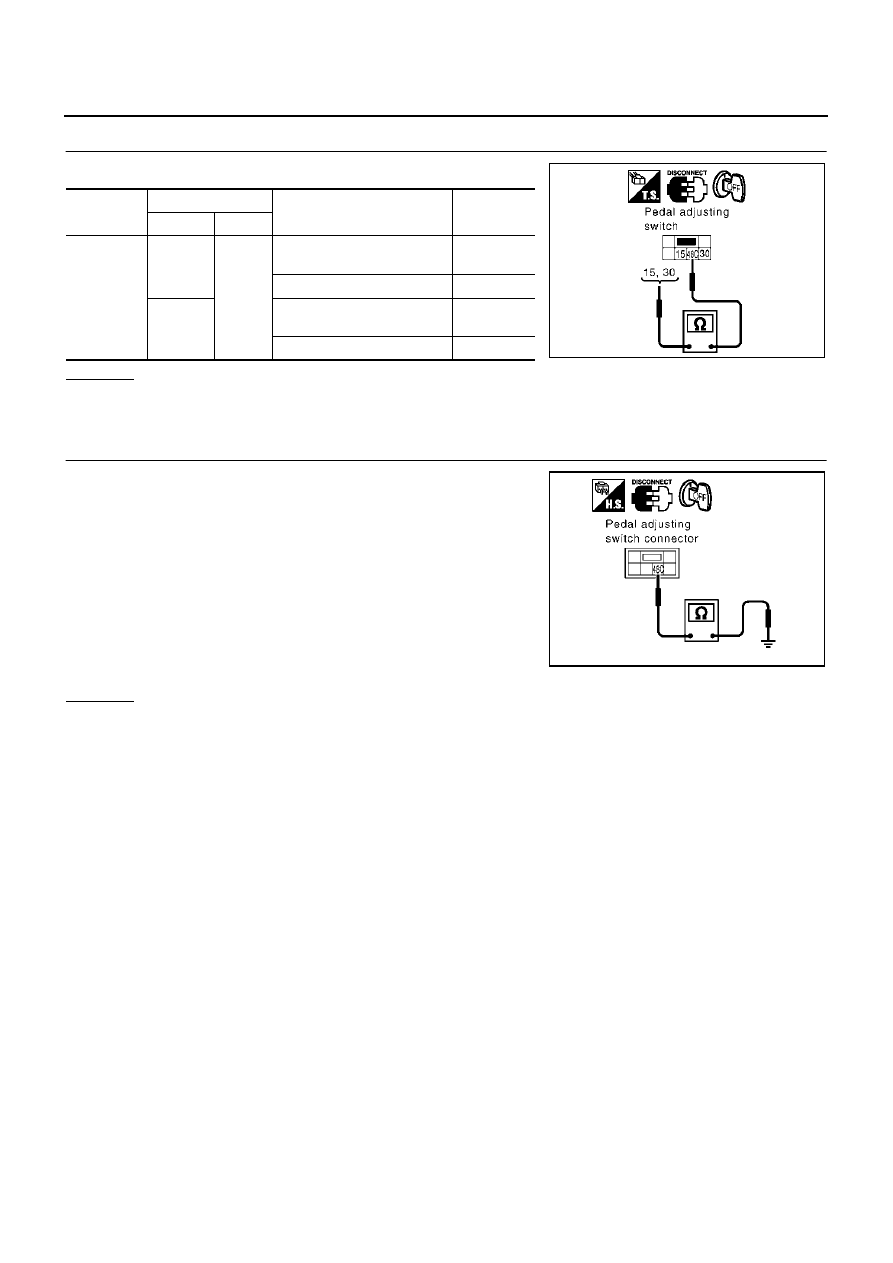

CHECK PEDAL ADJUSTING SWITCH

Check continuity between pedal adjust switch as follows.

OK or NG

OK

>> GO TO 4.

NG

>> Replace pedal adjusting switch.

4.

CHECK PEDAL ADJUSTING SWITCH GROUND CIRCUIT

Check continuity between pedal adjusting switch connector B306

terminal 48C (B) and ground.

OK or NG

OK

>> Check the condition of the harness and connector.

NG

>> Replace or replace harness between pedal adjusting switch and ground.

Connector

Terminals

Condition

Continuity

(+)

(–)

B306

15

48C

Pedal adjusting switch ON

(RR operation)

Yes

Pedal adjusting switch OFF

No

30

Pedal adjusting switch ON

(FR operation)

Yes

Pedal adjusting switch OFF

No

PIIA4593E

48C (B) – Ground

: Continuity should exist.

PIIA4594E