Nissan Murano Z50 (2003 year). Manual - part 177

LAN-446

[CAN]

CAN SYSTEM (TYPE 13)

Revision; 2004 April

2003 Murano

3.

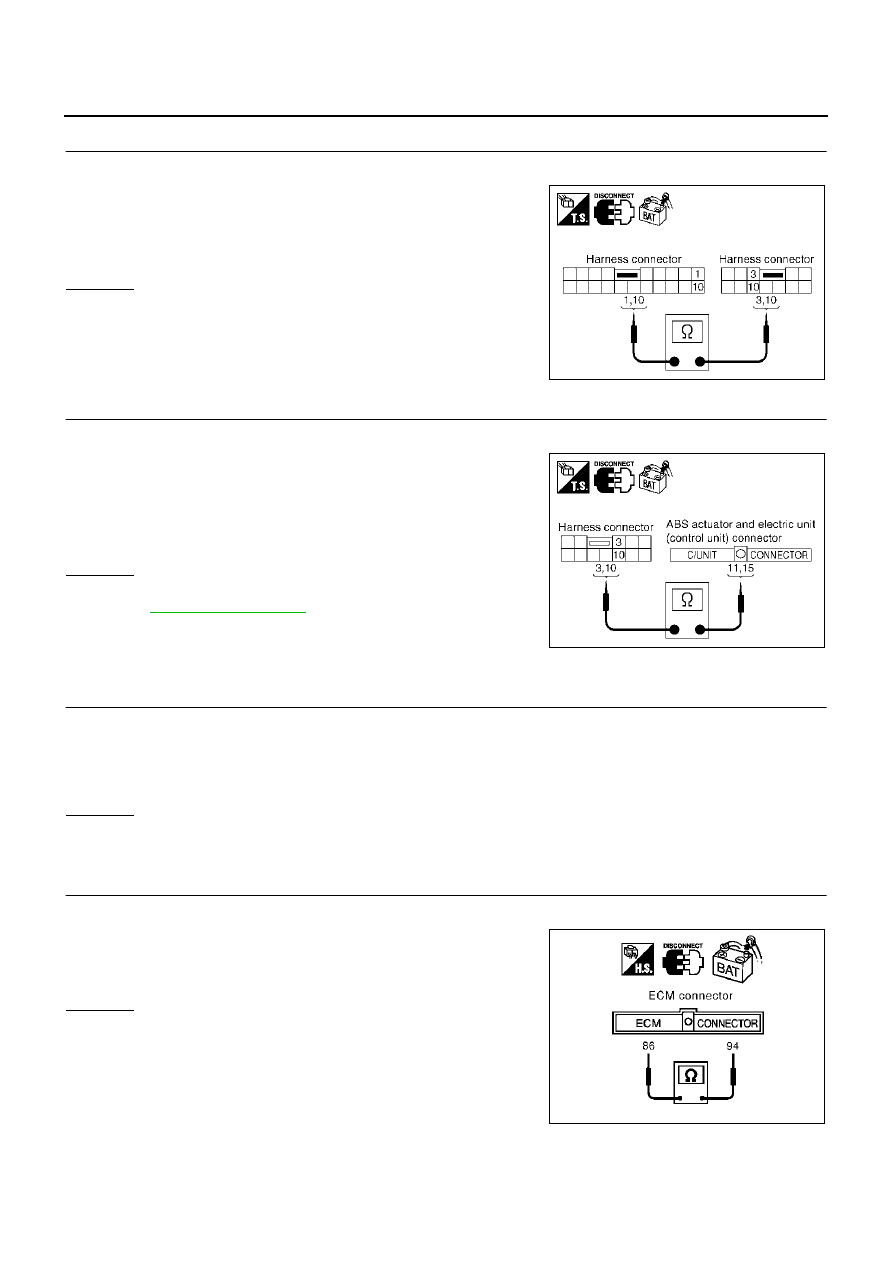

CHECK HARNESS FOR OPEN CIRCUIT

1.

Disconnect harness connector B4.

2.

Check continuity between harness connector B2 terminals 1 (L),

10 (Y) and harness connector B4 terminals 3 (L), 10 (Y).

OK or NG

OK

>> GO TO 4.

NG

>> Repair harness.

4.

CHECK HARNESS FOR OPEN CIRCUIT

1.

Disconnect ABS actuator and electric unit (control unit) connector.

2.

Check continuity between harness connector E105 terminals 3

(L), 10 (Y) and ABS actuator and electric unit (control unit) har-

ness connector E24 terminals 11 (L), 15 (Y).

OK or NG

OK

>> Connect all the connectors and diagnose again. Refer to

.

NG

>> Repair harness.

ECM Circuit Check

AKS006VI

1.

CHECK CONNECTOR

1.

Turn ignition switch OFF.

2.

Disconnect the negative battery terminal.

3.

Check terminals and connector of ECM for damage, bend and loose connection (control module side and

harness side).

OK or NG

OK

>> GO TO 2.

NG

>> Repair terminal or connector.

2.

CHECK HARNESS FOR OPEN CIRCUIT

1.

Disconnect ECM connector.

2.

Check resistance between ECM harness connector M80 termi-

nals 94 (L) and 86 (Y).

OK or NG

OK

>> Replace ECM.

NG

>> Repair harness between ECM and TCM.

1 (L) - 3 (L)

: Continuity should exist.

10 (Y) - 10 (Y)

: Continuity should exist.

SKIA5016E

3 (L) - 11 (L)

: Continuity should exist.

10 (Y) - 15 (Y)

: Continuity should exist.

SKIA5017E

94 (L) - 86 (Y)

: Approx. 108 - 132

Ω

PKIA0816E