Nissan Murano Z50 (2003 year). Manual - part 105

DTC P0456 EVAP CONTROL SYSTEM

EC-399

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision; 2004 April

2003 Murano

4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to

EC-655, "FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FULLER CAP)"

.

OK or NG

OK

>> GO TO 5.

NG

>> Replace fuel filler cap with a genuine one.

5.

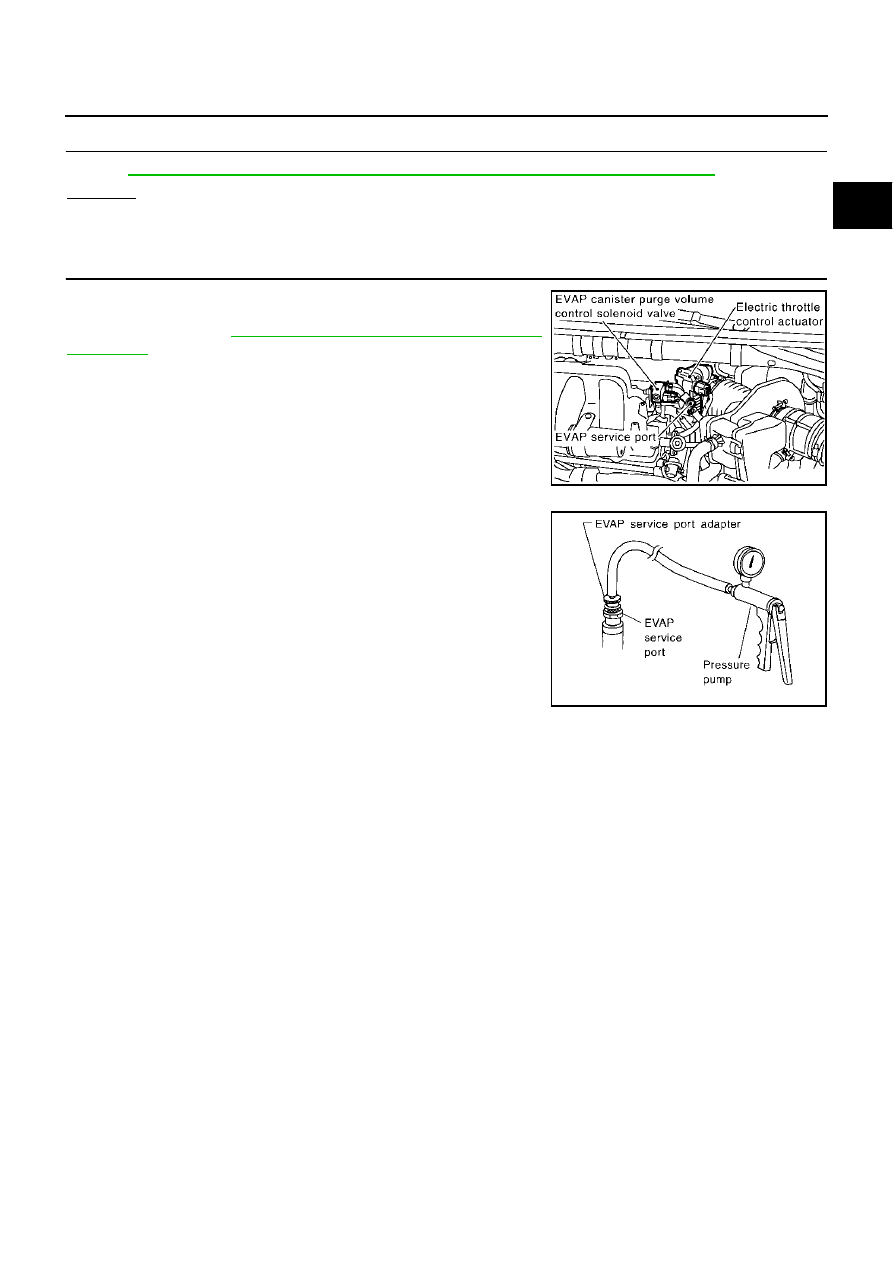

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely. For the location of EVAP

service port, refer to

EC-653, "EVAPORATIVE EMISSION LINE

NOTE:

Improper installation of the EVAP service port adapter to the EVAP service port may cause leaking.

Models with CONSULT-II>>GO TO 6.

Models without CONSULT-II>>GO TO 7.

PBIB1355E

SEF916U