Nissan Murano Z50 (2003 year). Manual - part 101

DTC P0340, P0345 CMP SENSOR (PHASE)

EC-335

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision; 2004 April

2003 Murano

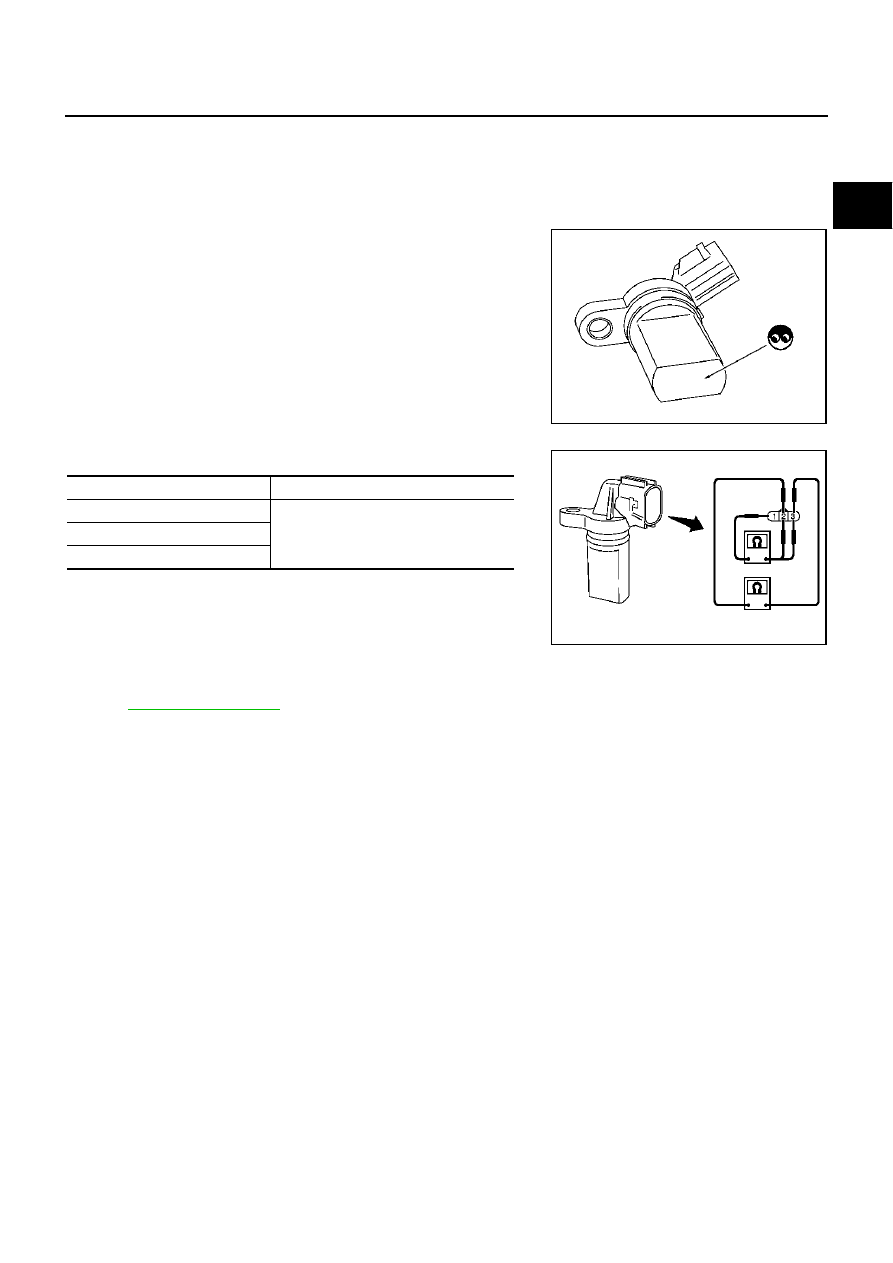

Component Inspection

ABS004GB

CAMSHAFT POSITION SENSOR (PHASE)

1.

Loosen the fixing bolt of the sensor.

2.

Disconnect camshaft position sensor (PHASE) harness connector.

3.

Remove the sensor.

4.

Visually check the sensor for chipping.

5.

Check resistance as shown in the figure.

Removal and Installation

ABS004GC

CAMSHAFT POSITION SENSOR (PHASE)

Refer to

PBIB0563E

Terminal No. (Polarity)

Resistance

Ω

[at 25

°

C (77

°

F)]

1 (+) - 2 (-)

Except 0 or

∞

1 (+) - 3 (-)

2 (+) - 3 (-)

PBIB0564E