Nissan Murano Z50 (2003 year). Manual - part 89

TROUBLE DIAGNOSIS

EC-143

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision; 2004 April

2003 Murano

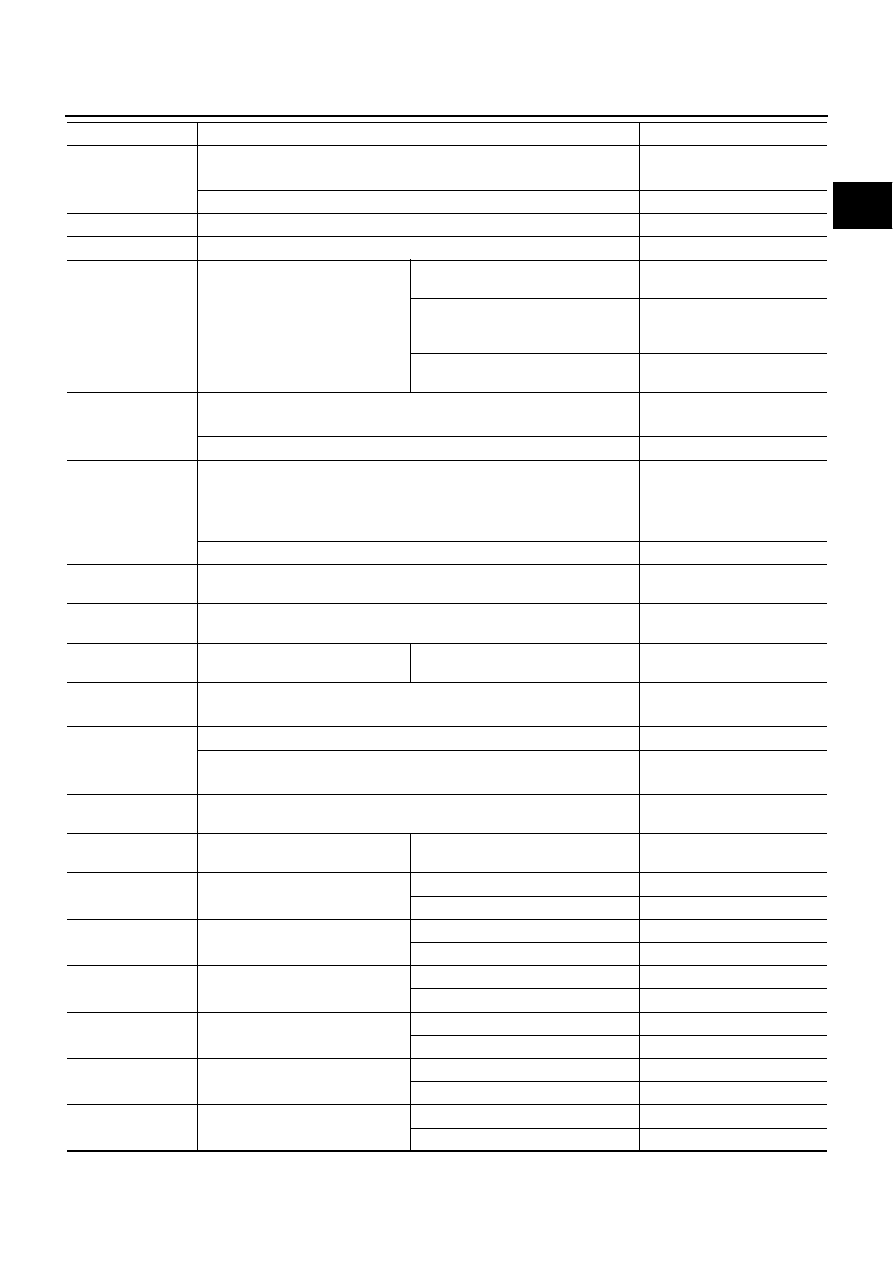

FUEL PUMP RLY

●

For 1 second after turning ignition switch ON

●

Engine running or cranking

ON

●

Except above conditions

OFF

VENT CONT/V

●

Ignition switch: ON

OFF

THRTL RELAY

●

Ignition switch: ON

ON

COOLING FAN

●

Engine: After warming up, idle

the engine

●

Air conditioner switch: OFF

Engine coolant temperature is 94

°

C

(201

°

F) or less

OFF

Engine coolant temperature is

between 95

°

C (203

°

F) and 99

°

C

(210

°

F)

LOW

Engine coolant temperature is 100

°

C

(212

°

F) or more

HI

HO2S1 HTR (B1)

HO2S1 HTR (B2)

●

Engine: After warming up

●

Engine speed: Below 3,600 rpm

ON

●

Engine speed: Above 3,600 rpm

OFF

HO2S2 HTR (B1)

HO2S2 HTR (B2)

●

Engine speed is below 3,600 rpm after the following conditions are met.

–

Engine: After warming up

–

Keeping the engine speed between 3,500 and 4,000 rpm for one minute

and at idle for one minute under no load

ON

●

Engine speed: Above 3,600 rpm

OFF

I/P PULLY SPD

●

Vehicle speed: More than 20 km/h (12 MPH)

Almost the same speed as the

tachometer indication

VEHICLE SPEED

●

Turn drive wheels and compare CONSULT-II value with the speedometer

indication.

Almost the same speed as the

speedometer indication

TRVL AFTER MIL

●

Ignition switch: ON

Vehicle has traveled after MIL has

turned ON.

0 - 65,535 km

(0 - 40,723 mile)

O2SEN HTR DTY

●

Engine coolant temperature when engine started: More than 80

°

C (176

°

F)

●

Engine speed: Below 3,600 rpm

Approx. 50%

AC PRESS SEN

●

Ignition switch: ON (Engine stopped)

Approx. 0V

●

Engine: Idle

●

Air conditioner switch: ON

1.0 - 4.0V

VEH SPEED SE

●

Turn drive wheels and compare CONSULT-II value with the speedometer

indication.

Almost the same speed as the

speedometer indication

SET VHCL SPD

●

Engine: Running

ASCD: Operating.

The preset vehicle speed is

displayed.

MAIN SW

●

Ignition switch: ON

CRUISE switch: Pressed

ON

CRUISE switch: Released

OFF

CANCEL SW

●

Ignition switch: ON

CANCEL switch: Pressed

ON

CANCEL switch: Released

OFF

RESUME/ACC SW

●

Ignition switch: ON

ACCEL/RES switch: Pressed

ON

ACCEL/RES switch: Released

OFF

SET SW

●

Ignition switch: ON

COAST/SET switch: Pressed

ON

COAST/SET switch: Released

OFF

BRAKE SW1

●

Ignition switch: ON

Brake pedal: Fully released

ON

Brake pedal: Slightly depressed

OFF

BRAKE SW2

●

Ignition switch: ON

Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed

ON

MONITOR ITEM

CONDITION

SPECIFICATION