Nissan Murano Z50 (2003 year). Manual - part 86

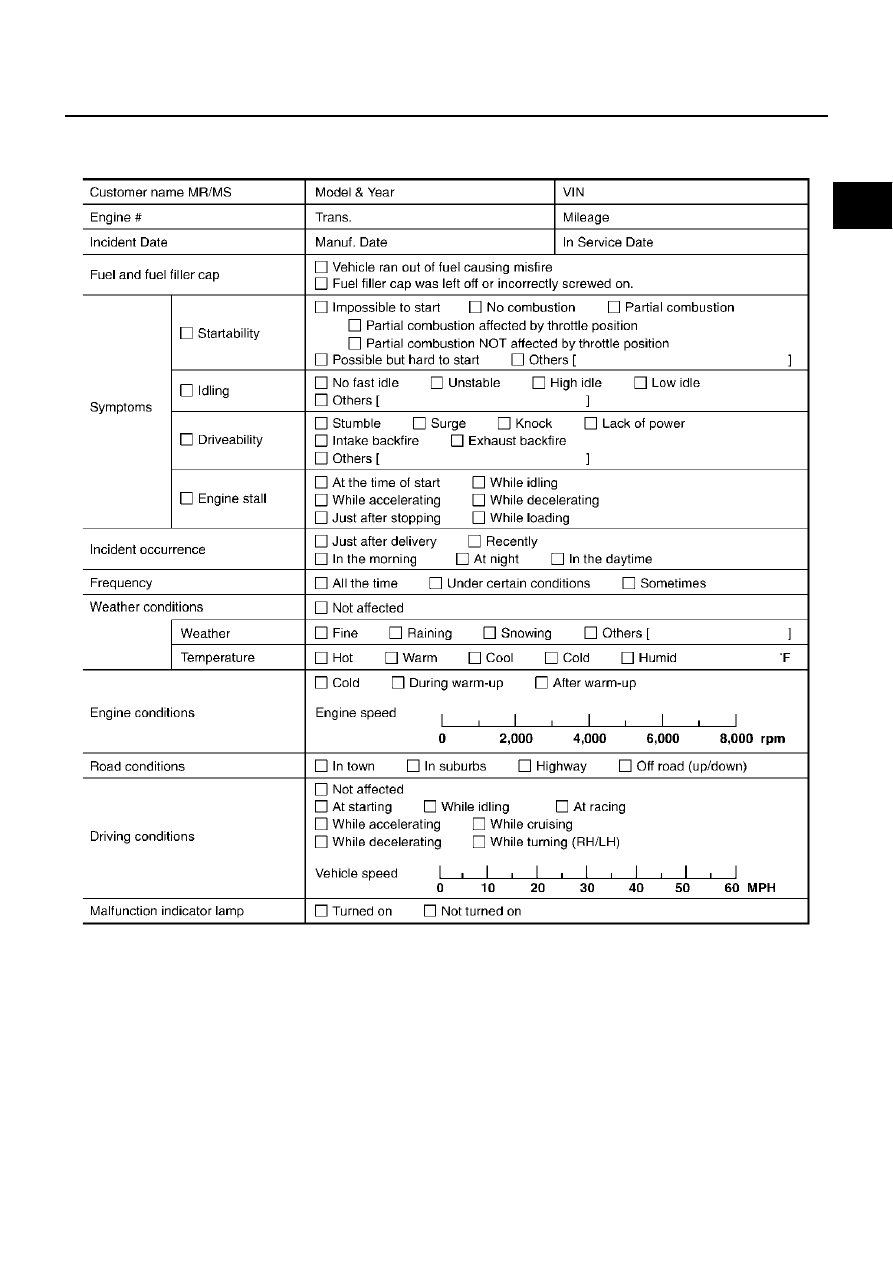

TROUBLE DIAGNOSIS

EC-95

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision; 2004 April

2003 Murano

●

Fuel filler cap was left off or incorrectly screwed on, allowing fuel to evaporate into the atmosphere.

Worksheet Sample

MTBL0017