Nissan Murano Z50 (2003 year). Manual - part 65

DTC P0615 START SIGNAL CIRCUIT

CVT-81

D

E

F

G

H

I

J

K

L

M

A

B

CVT

Revision; 2004 April

2003 Murano

TCM terminal and data are reference values. Measured between each terminal and ground.

Diagnostic Procedure

ACS001TQ

1.

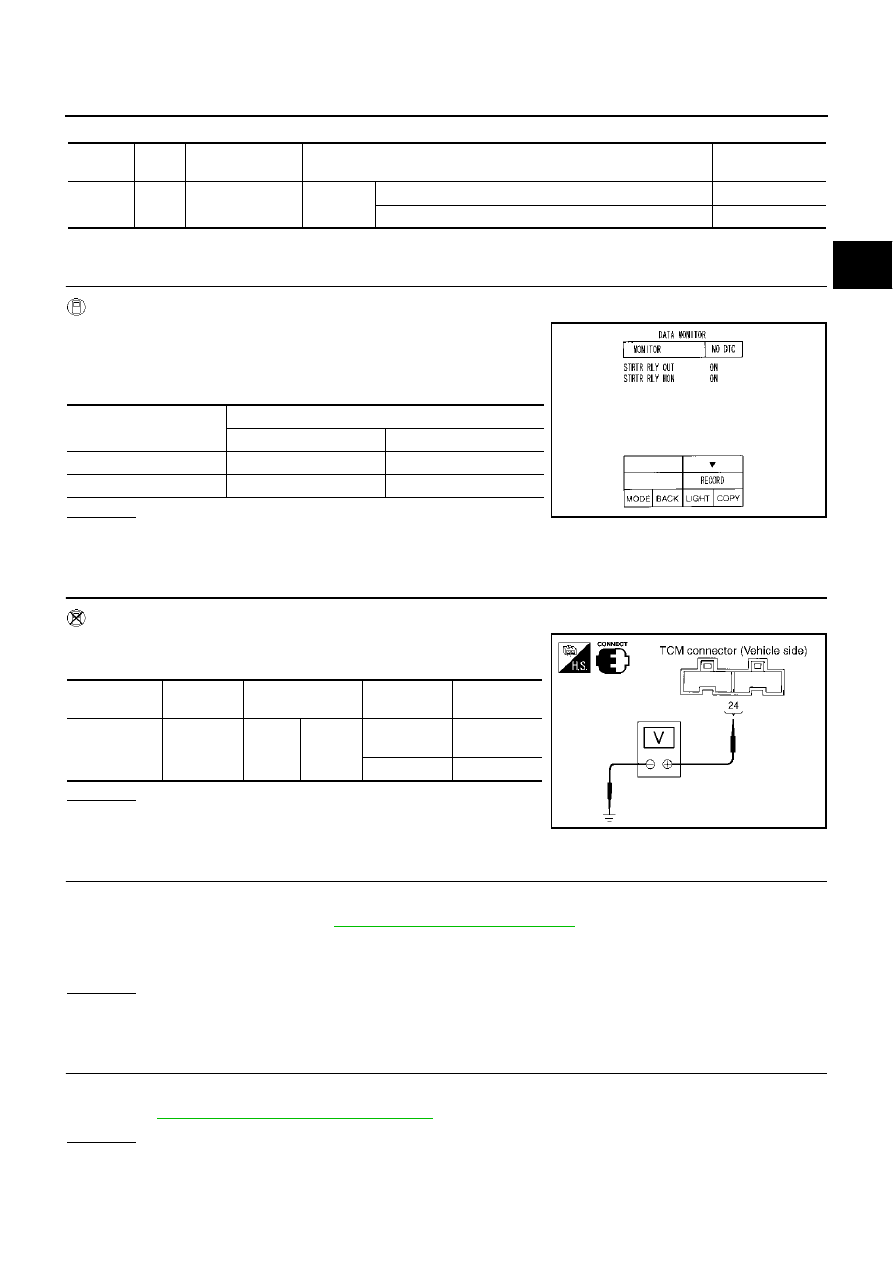

CHECK PNP RELAY (STARTER RELAY) (WITH CONSULT-II)

With CONSULT-II

1.

Turn ignition switch “ON”. (Do not start engine.)

2.

Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “TRANSMISSION” with CONSULT-II and check monitor

“STRTR RLY OUT”, “STRTR RLY MON”(PNP relay) ON/OFF.

OK or NG

OK

>> GO TO 4.

NG

>> GO TO 3.

2.

CHECK PNP RELAY (STARTER RELAY) (WITHOUT CONSULT-II)

Without CONSULT-II

1.

Turn ignition switch “ON”. (Do not start engine.)

2.

Check voltage between the TCM connector and ground.

OK or NG

OK

>> GO TO 4.

NG

>> GO TO 3.

3.

DETECT MALFUNCTIONING ITEM

Check the following:

●

PNP relay (starter relay). Refer to

.

●

Open or short-circuits in the harness between TCM and the PNP relay

●

Ground circuit for the PNP relay (starter relay)

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace damaged parts.

4.

CHECK DTC

Check again.

●

Refer to

CVT-79, "DTC Confirmation Procedure"

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 5.

Terminal

No.

Wire

color

Item

Condition

Data (Approx.)

24

G/O

PNP relay

(Starter relay)

IGN ON

Selector lever in “N”, “P” position.

Battery voltage

Selector lever in other position.

0V

Shift position

Item

“STRTR RLY OUT”

“STRTR RLY MON”

N and P

ON

ON

R, D and L

OFF

OFF

SCIA2274E

Item

Connector

No.

Terminal No.

(Wire color)

Shift position

Voltage

(Approx.)

PNP relay

(Starter relay)

F103

24

(G/O)

Ground

N and P

Battery

voltage

R, D and L

0V

SCIA2022E