Nissan Murano Z50 (2003 year). Manual - part 57

TROUBLE DIAGNOSIS

BRC-133

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

Revision; 2004 April

2003 Murano

3.

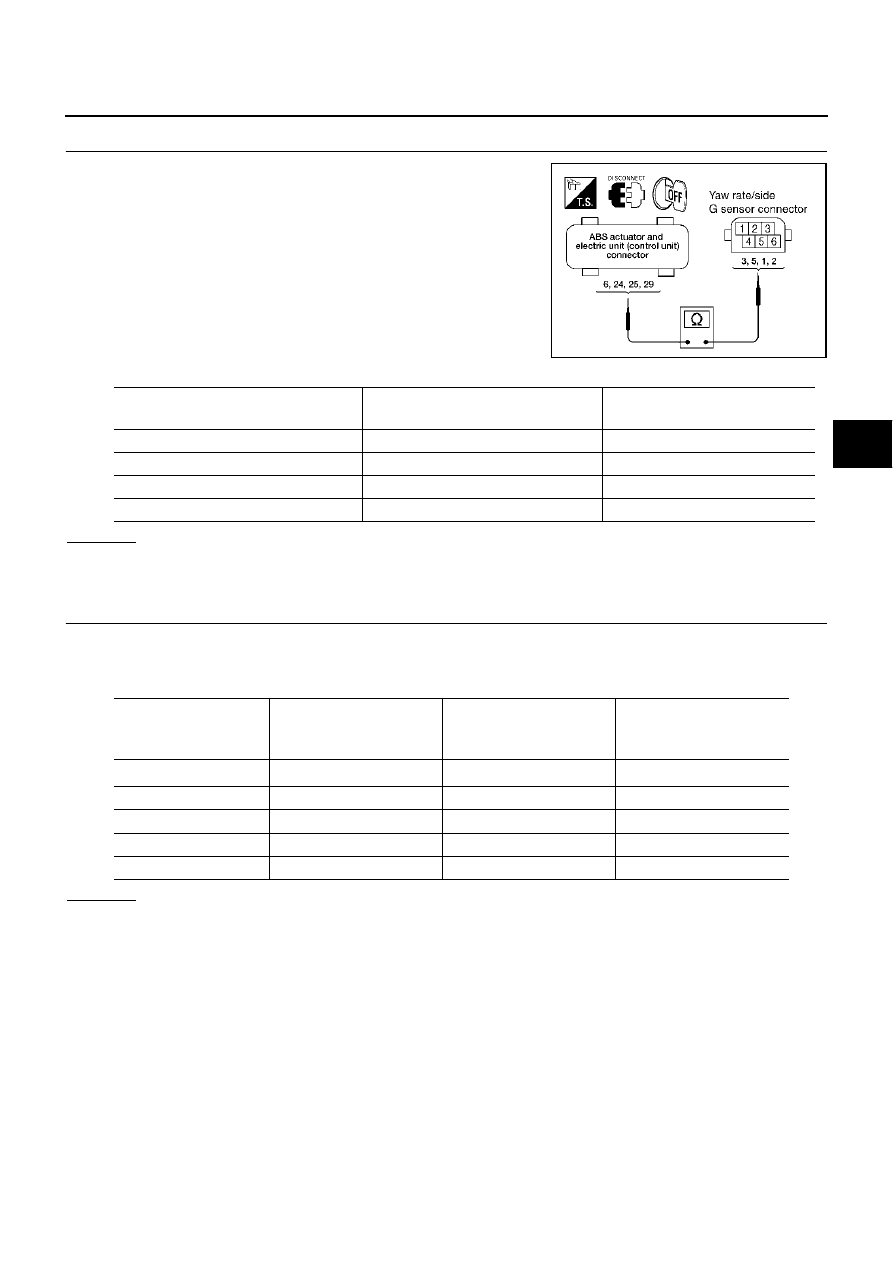

CHECK YAW RATE SENSOR/SIDE G SENSOR HARNESS

1.

Turn ignition switch OFF and disconnect yaw rate/side/decel G

sensor connector M61 and ABS actuator and electric unit (con-

trol unit) connector E24.

2.

Check continuity between ABS actuator and electric unit (control

unit) vehicle side connector and yaw rate/side/decel G sensor

vehicle side connector.

OK or NG

OK

>> GO TO 4.

NG

>> If open or short in harness, repair or replace harness.

4.

CHECK YAW RATE SENSOR/SIDE/DECEL G SENSOR

1.

Connect yaw rate /side/decel G sensor M61 and ABS actuator and electric unit (control unit) connector

E24.

2.

Use “Data Monitor” to check if yaw rate sensor/side/decel G sensor are normal.

OK or NG

OK

>> Perform ABS actuator and electric unit (control unit) self diagnosis again.

NG

>> Replace the malfunctioning yaw rate sensor/side/decel G sensor, and then re-conduct ABS actu-

ator and electric unit (control unit) self-diagnosis.

PFIA0460E

ABS actuator and electric unit

(control unit)

Yaw rate/side/decel G sensor

Continuity

6 (G/R)

3 (G/R)

Yes

24 (P/L)

5 (P/L)

Yes

25 (W)

1 (W/G)

Yes

29 (R)

2 (R/Y)

Yes

Vehicle status

Yaw rate sensor

(Data monitor stan-

dard)

Side G sensor

(Data monitor stan-

dard)

Decel G sensor

(Data monitor stan-

dard)

When stopped

–4 to +4deg/s

–1.1 to +1.1 m/s

2

–0.11 G to +0.11 G

Right turn

Negative value

Negative value

–

Left turn

Positive value

Positive value

–

Speed up

–

–

Negative value

Speed down

–

–

Positive value