Nissan Murano Z50 (2003 year). Manual - part 52

TROUBLE DIAGNOSIS

BRC-53

[ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

Revision; 2004 April

2003 Murano

6.

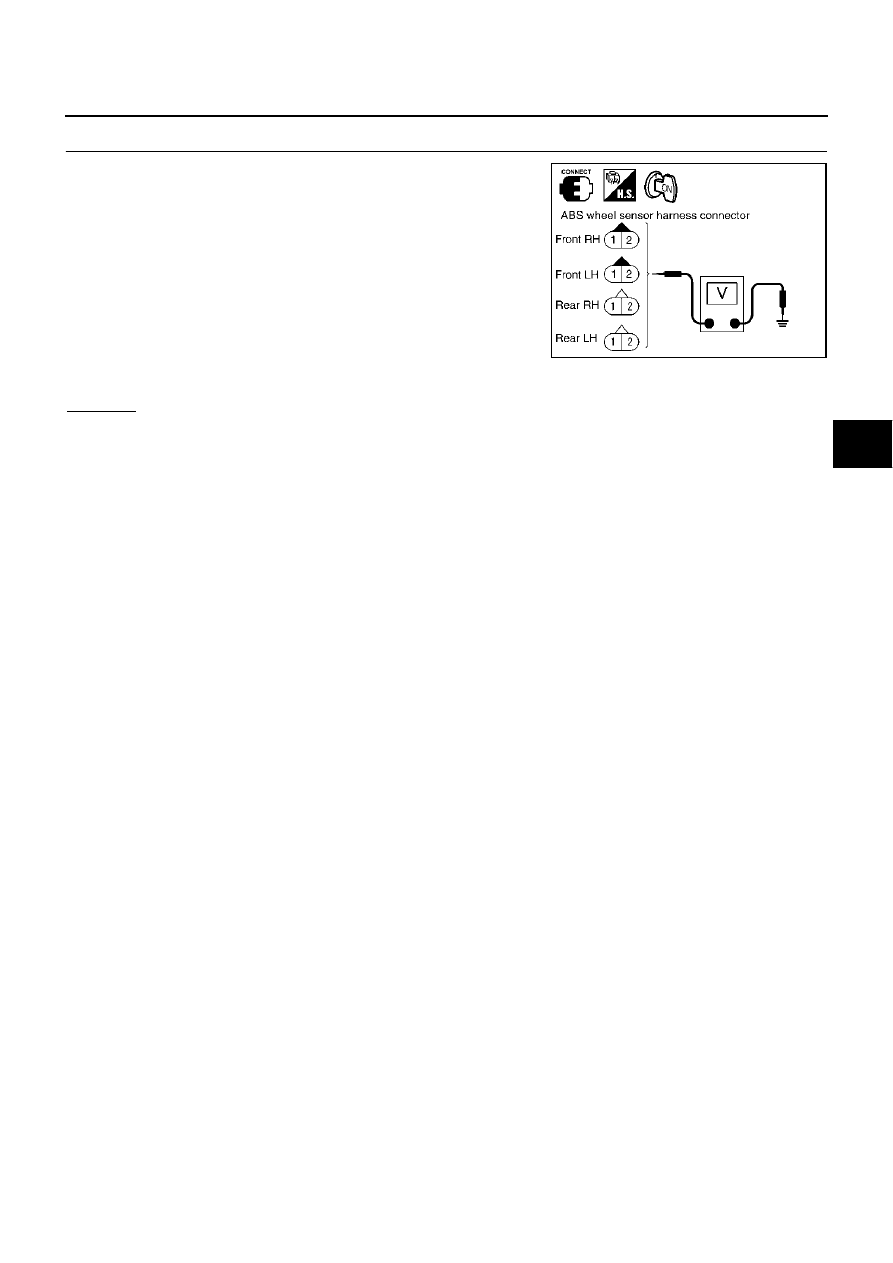

CHECK WHEEL SENSOR POWER SUPPLY CIRCUIT

1.

Connect wheel sensor connector E20 (FR - LH), E27 (FR - RH),

B202 (RR - LH), B203 (RR - RH) and ABS actuator and electric

unit (control unit) connector E24.

2.

Turn ignition switch ON and check voltage between power sup-

ply terminal and ground.

OK or NG

OK

>> Replace wheel sensor.

NG

>> Replace ABS actuator and electric unit (control unit).

Voltage

Front RH

1 (B) - Ground

: 8 V or more

Front LH

1 (G) - Ground

: 8 V or more

Rear RH

1 (LG) - Ground

: 8 V or more

Rear LH

1 (L) - Ground

: 8 V or more

PFIA0427E