Nissan Murano Z50 (2003 year). Manual - part 48

FRONT DISC BRAKE

BR-29

C

D

E

G

H

I

J

K

L

M

A

B

BR

Revision; 2004 April

2003 Murano

INSTALLATION

CAUTION:

●

Refill with new brake fluid “DOT3”

●

Do not reuse drained brake fluid.

1.

Install disc rotor.

2.

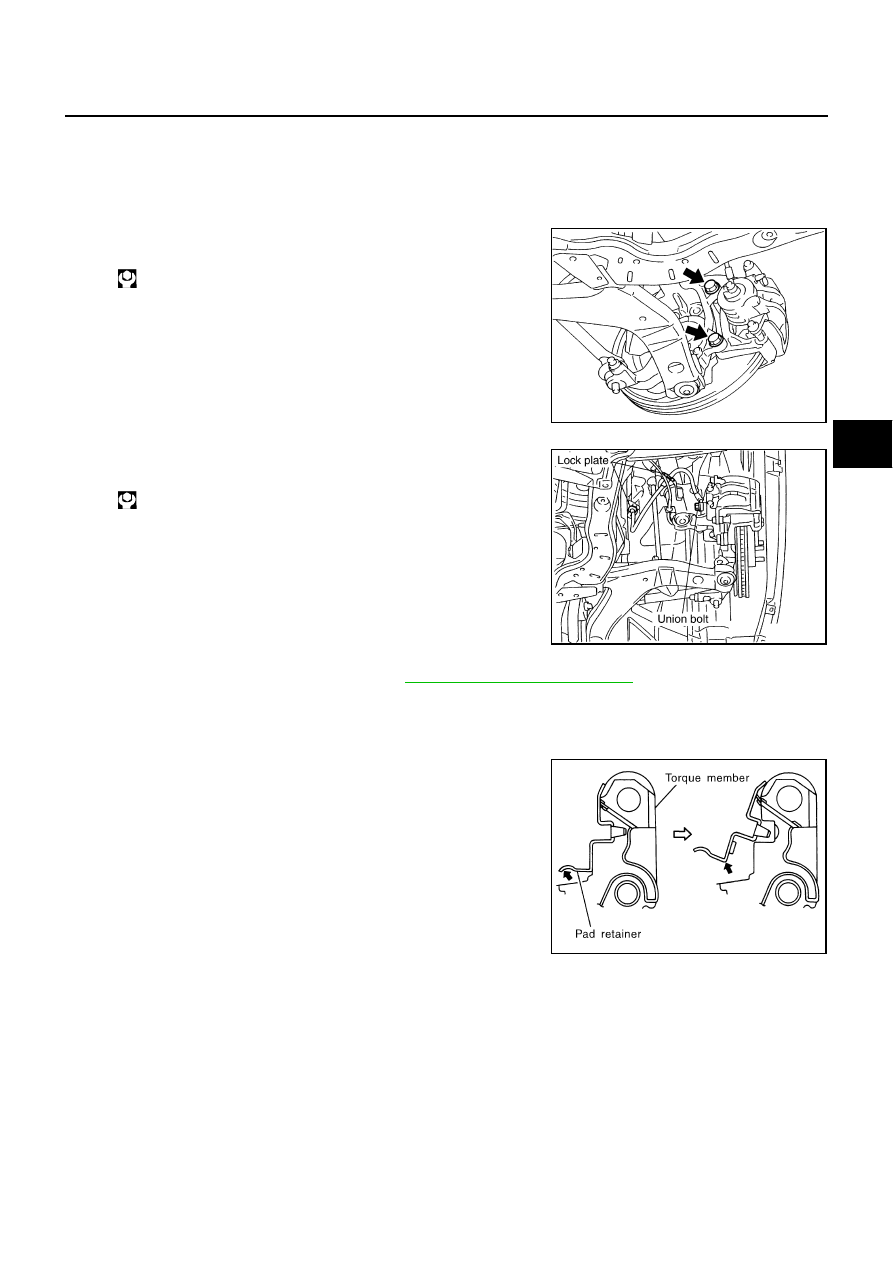

Install caliper assembly to the vehicle, and tighten bolts to the

specified torque.

CAUTION:

Before installing caliper assembly to the knuckle, wipe off

oil the knuckle spindle washers and mounting surface of

caliper assembly.

3.

Install brake hose to the brake caliper assembly, and tighten

union bolts to the specified torque.

CAUTION:

●

Do not reuse the copper washer for union bolts.

●

Attach the brake hose to the brake hose mounting boss.

4.

Refill new brake fluid and bleed air. Refer to

BR-12, "Bleeding Brake System"

5.

Install the tires to the vehicle.

Disassembly and Assembly of Brake Caliper Assembly

AFS0017F

DISASSEMBLY

1.

Remove slide pin bolts, and then remove the pads, shim, shim

cover, and pad retainers from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indicated by the arrow in the figure so

that it does not deform.

2.

Remove sliding pins and sliding pin boots from torque member.

: 137 - 176 N·m (14 - 17 kg-m, 101 - 129 ft-lb)

PFIA0411E

: 16.7 - 19.6 N·m (1.7 - 1.9 kg-m, 13 - 14 ft-lb)

PFIA0404E

SBR556E