Nissan Murano Z51 (2008 year). Manual - part 407

WT-106

< ON-VEHICLE REPAIR >

ROAD WHEEL TIRE ASSEMBLY

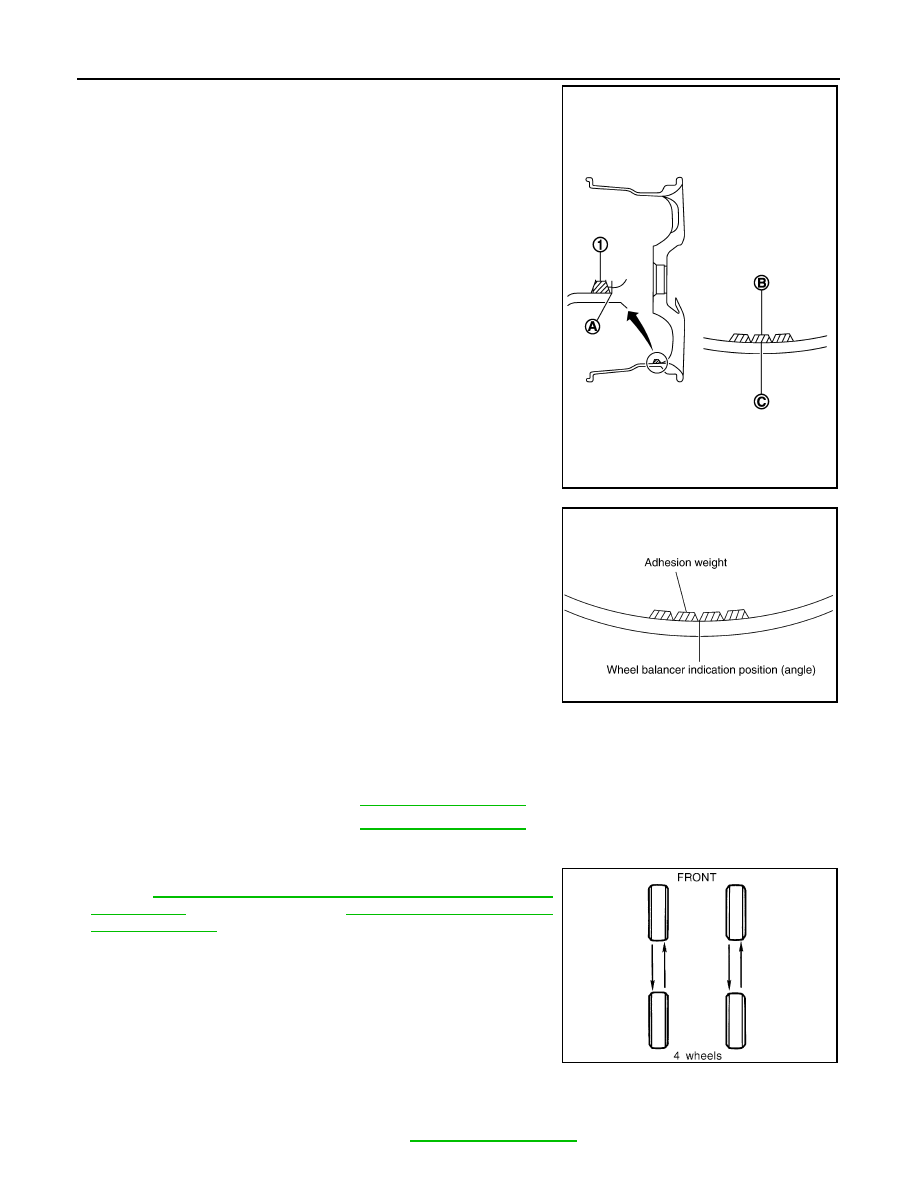

• When installing balance weight (1) to road wheels, set it into

the grooved area (A) on the inner wall of the road wheel as

shown in the figure so that the balance weight center (B) is

aligned with the tire balance machine indication position

(angle) (C).

CAUTION:

• Always use genuine NISSAN adhesion balance weights.

• Balance weights are non-reusable; always replace with

new ones.

• Do not install more than three sheets of balance weight.

c.

If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3.

Start the tire balance machine again.

4.

Install drive-in balance weight on inner side of road wheel in the

tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weight.

5.

Start the tire balance machine. Make sure that inner and outer

residual unbalance values are 5 g (0.17 oz) each or below.

6.

If either residual unbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to

MA-5, "FOR NORTH AMERICA : Explanation of General

(For North America),

(For Mexico).

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the T-type spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

JPEIC0040ZZ

Limit

Dynamic (At flange):

Refer to

Static (At flange):

Refer to

PEIA0033E

Wheel nuts tighting torque:

Refer to

.

SMA829C

Revision: 2008 October

2009 Murano