Nissan Murano Z51 (2008 year). Manual - part 400

WCS-92

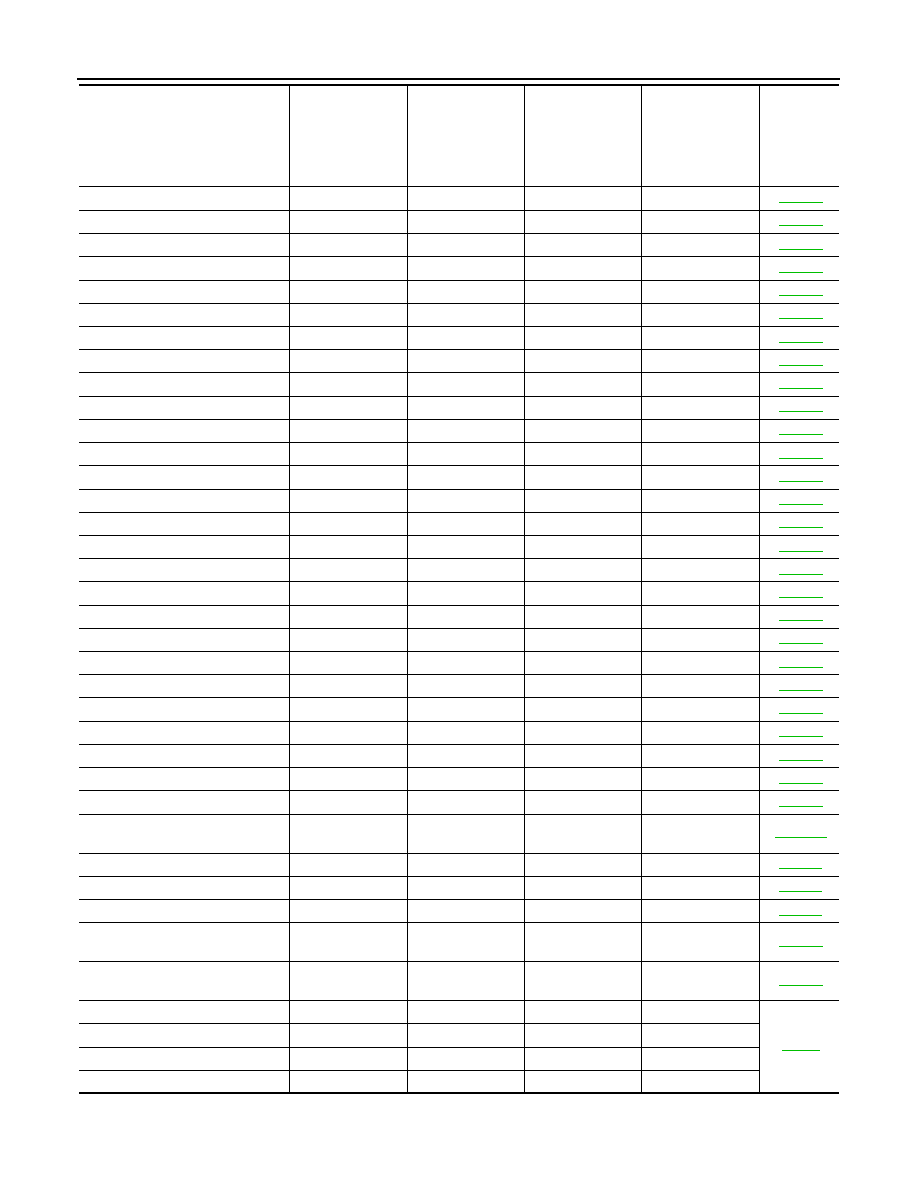

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

B2555: STOP LAMP

—

×

—

—

B2556: PUSH-BTN IGN SW

—

×

×

—

B2557: VEHICLE SPEED

×

×

×

—

B2560: STARTER CONT RELAY

×

×

×

—

B2562: LOW VOLTAGE

—

×

—

—

B2601: SHIFT POSITION

×

×

×

—

B2602: SHIFT POSITION

×

×

×

—

B2603: SHIFT POSI STATUS

×

×

×

—

B2604: PNP SW

×

×

×

—

B2605: PNP SW

×

×

×

—

B2606: S/L RELAY

×

×

×

—

B2607: S/L RELAY

×

×

×

—

B2608: STARTER RELAY

×

×

×

—

B2609: S/L STATUS

×

×

×

—

B260A: IGNITION RELAY

×

×

×

—

B260B: STEERING LOCK UNIT

—

×

×

—

B260C: STEERING LOCK UNIT

—

×

×

—

B260D: STEERING LOCK UNIT

—

×

×

—

B260F: ENG STATE SIG LOST

×

×

×

—

B2612: S/L STATUS

×

×

×

—

B2614: ACC RELAY CIRC

—

×

×

—

B2615: BLOWER RELAY CIRC

—

×

×

—

B2616: IGN RELAY CIRC

—

×

×

—

B2617: STARTER RELAY CIRC

×

×

×

—

B2618: BCM

×

×

×

—

B2619: BCM

×

×

×

—

B261A: PUSH-BTN IGN SW

—

×

×

—

B261E: VEHICLE TYPE

×

×

×

(Turn ON for 15

seconds)

—

B2621: INSIDE ANTENNA

—

×

—

—

B2622: INSIDE ANTENNA

—

×

—

—

B2623: INSIDE ANTENNA

—

×

—

—

B26E9: S/L STATUS

×

×

×

(Turn ON for 15

seconds)

—

B26EA: KEY REGISTRATION

—

×

×

(Turn ON for 15

seconds)

—

C1704: LOW PRESSURE FL

—

—

—

×

C1705: LOW PRESSURE FR

—

—

—

×

C1706: LOW PRESSURE RR

—

—

—

×

C1707: LOW PRESSURE RL

—

—

—

×

CONSULT display

Fail-safe

Freeze Frame

Data

•Vehicle Speed

•Odo/Trip Meter

•Vehicle Condi-

tion

Intelligent Key

warning lamp ON

Tire pressure

monitor warning

lamp ON

Reference

page

Revision: 2008 October

2009 Murano