Nissan Murano Z51 (2008 year). Manual - part 387

VTL-12

< PRECAUTION >

[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

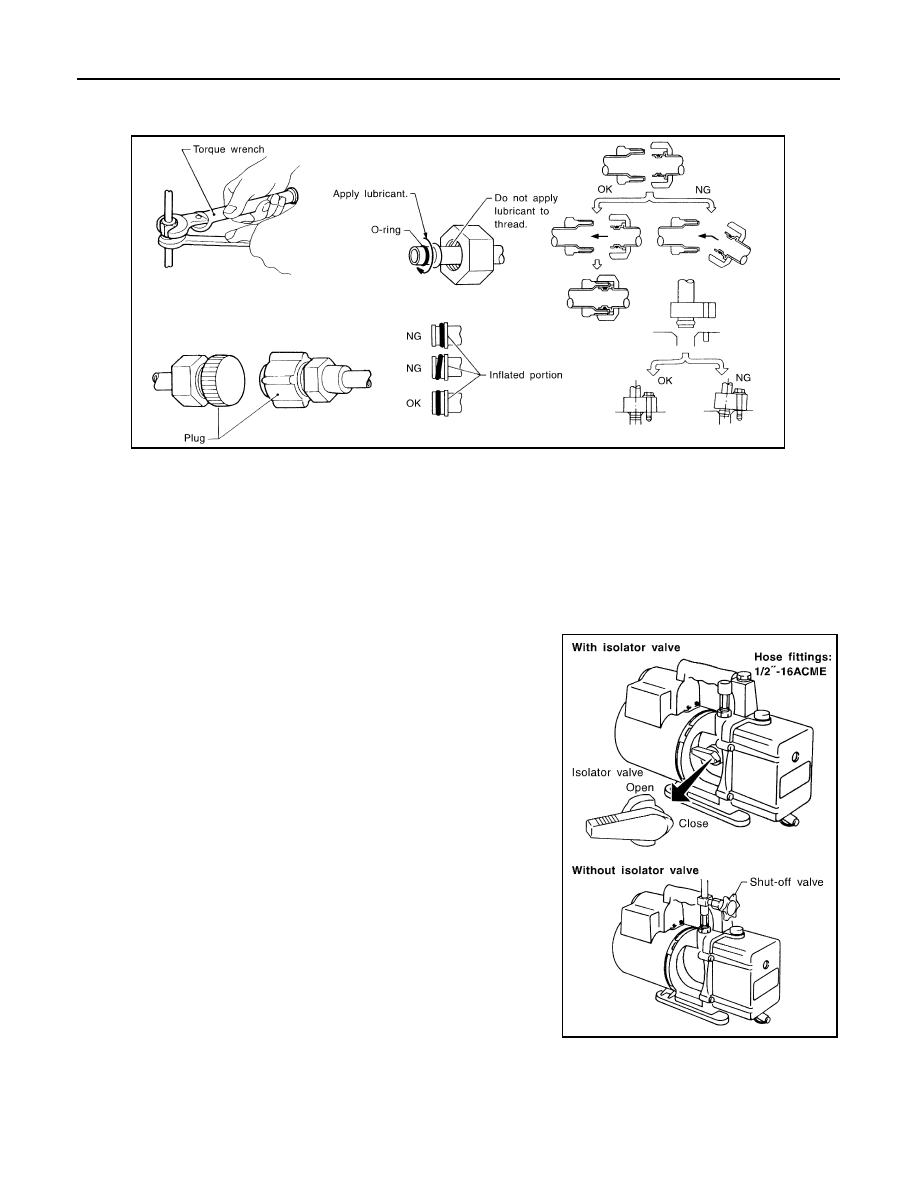

• Perform leakage test and check that there is no leakage from connections after connecting the line.

Disconnect the line and replace the O-ring when the refrigerant leakage point is found. Then tighten

the connections of seal seat to the specified torque.

Service Equipment

INFOID:0000000003072881

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer instructions for tester operation and tester maintenance.

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric pres-

sure. So the vacuum pump lubricant may migrate out of the pump

into the service hose. This is possible when the pump is switched

OFF after evacuation (vacuuming) and the hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as per the following procedure.

• Vacuum pumps usually have a manual isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

• Use a hose equipped with a manual shut-off valve near the pump

end for pumps without an isolator. Close the valve to isolate the

hose from the pump.

• Disconnect the hose from the pump if the hose has an automatic

shut-off valve. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under the no vacuum condition. Such valves may restrict the ability

of the pump to create a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

RHA861F

RHA270DA

Revision: 2008 October

2009 Murano