Nissan Murano Z51 (2008 year). Manual - part 376

CONTROL SYSTEM

TM-19

< FUNCTION DIAGNOSIS >

[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

CONTROL SYSTEM

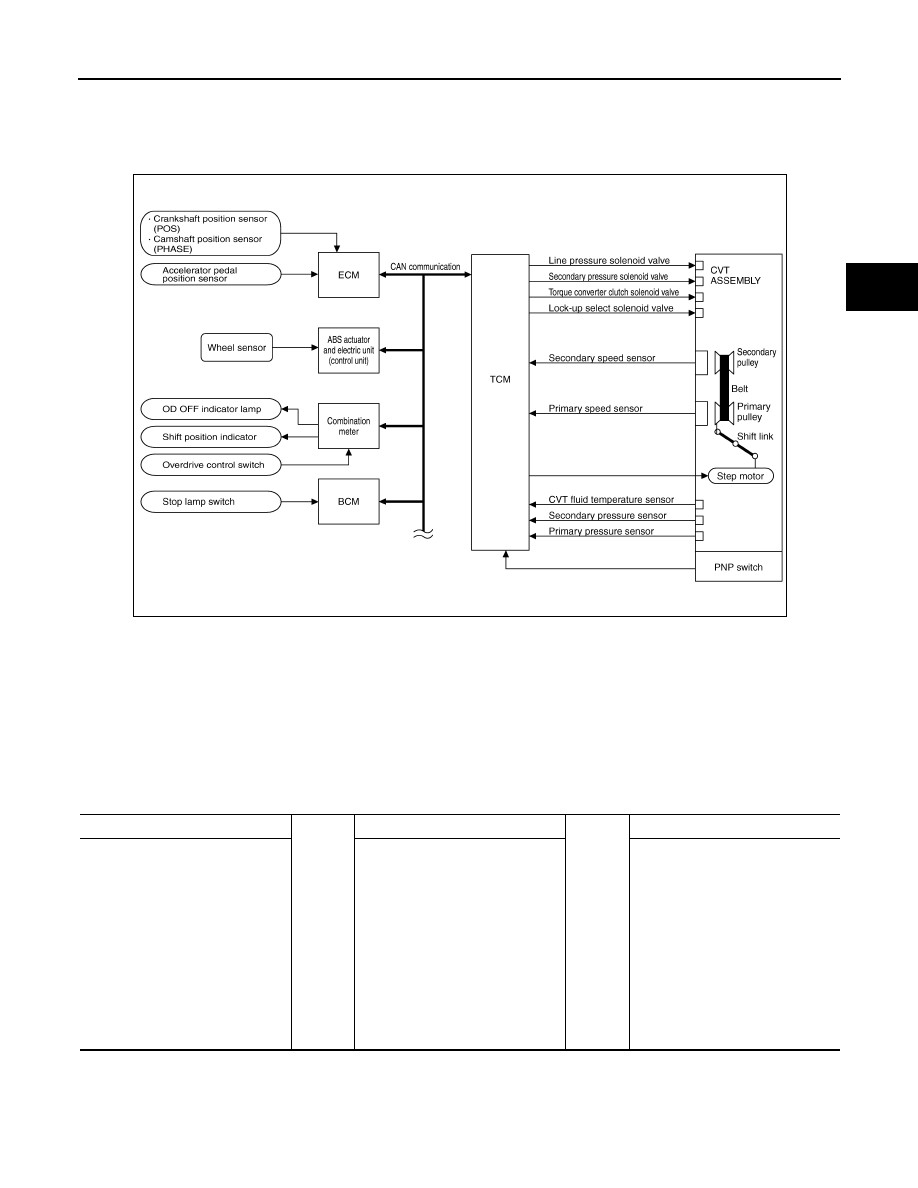

System Diagram

INFOID:0000000003305989

System Description

INFOID:0000000003305990

The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

TCM FUNCTION

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting point, and lock-up operation.

• Send required output signals to the step motor and the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

JPDIA0622GB

SENSORS (or SIGNAL)

⇒

TCM

⇒

ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Overdrive control switch signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Primary pressure sensor

Secondary pressure sensor

Shift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III communication line

Duet-EA control

CAN system

On board diagnosis

Step motor

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid valve

OD OFF indicator lamp

Shift position indicator

Starter relay

Revision: 2008 October

2009 Murano