Nissan Murano Z51 (2008 year). Manual - part 308

RSU-2

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

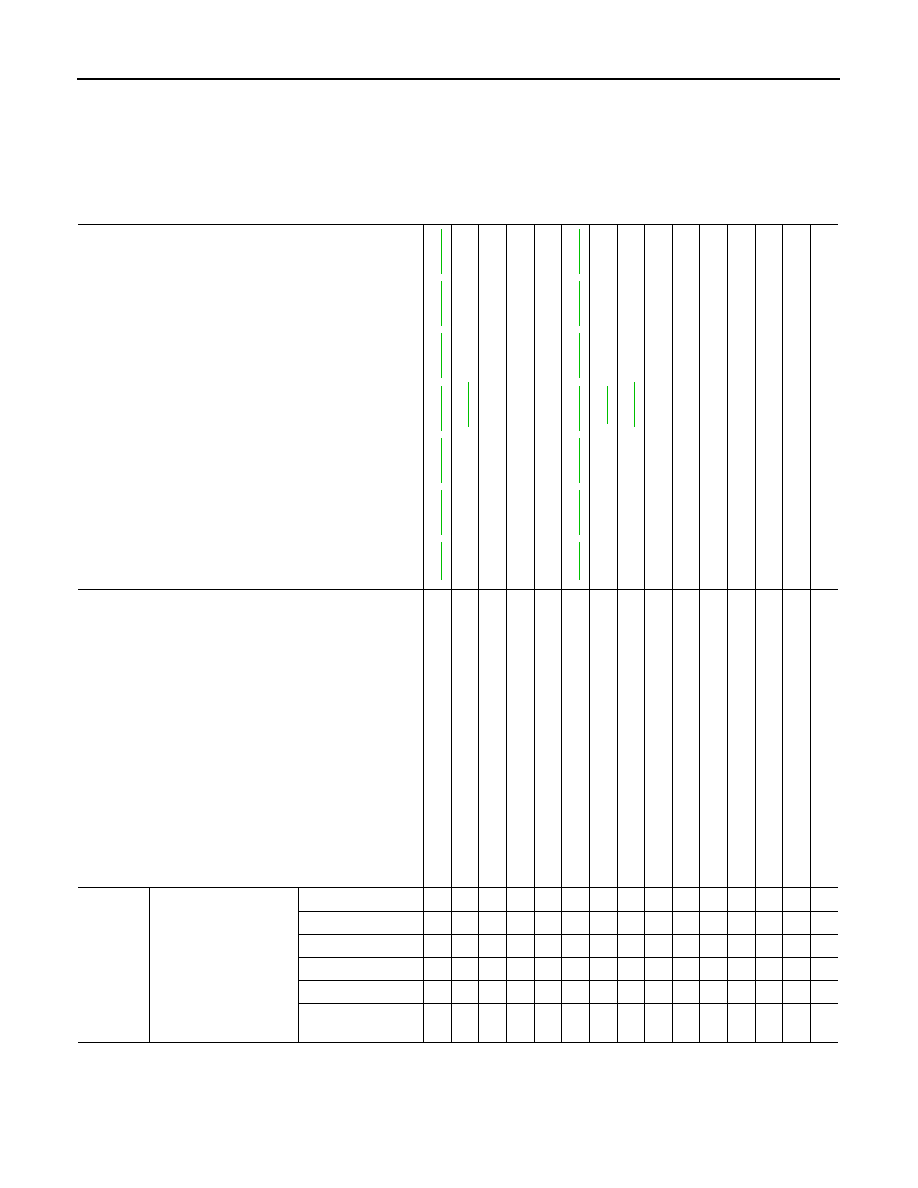

NVH Troubleshooting Chart

INFOID:0000000003544442

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

,

,

,

,

,

,

—

—

—

,

,

,

,

,

,

NVH in DLN

section

NVH in DLN

section

NVH in RAX and RSU sections

NVH in

WT section

NVH in

WT section

NVH in RAX

section

NVH in BR

section

Possible cause and SUSPECTED PARTS

Im

pro

pe

r in

st

a

llat

ion

,

lo

os

en

es

s

Sh

oc

k

ab

so

rbe

r d

e

fo

rma

tio

n,

da

ma

ge

or

de

fle

c

tion

Bu

s

h

in

g

or m

o

u

n

ting

d

e

te

rio

rati

o

n

Part

s interference

S

p

ri

ng fat

igu

e

Su

s

pen

s

ion

lo

os

en

es

s

In

c

o

rre

ct whee

l ali

g

n

m

e

n

t

S

tab

ilize

r b

a

r f

a

ti

gu

e

PROPELLE

R

SHAFT (A

WD)

DIF

F

ERENTI

AL (A

W

D

)

REA

R

AXLE

AND REAR S

U

S

PENSION

TI

RE

ROAD WH

E

E

L

DRIV

E SHAFT

(A

WD)

BRA

K

E

Symptom

REAR SUSPENSION

Noise

×

×

×

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

×

Poor quality ride or

handling

×

×

×

×

×

×

×

×

×

×

Revision: 2008 October

2009 Murano