Nissan Murano Z51 (2008 year). Manual - part 243

VANITY MIRROR LAMP

INL-117

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

M

A

B

INL

N

O

P

VANITY MIRROR LAMP

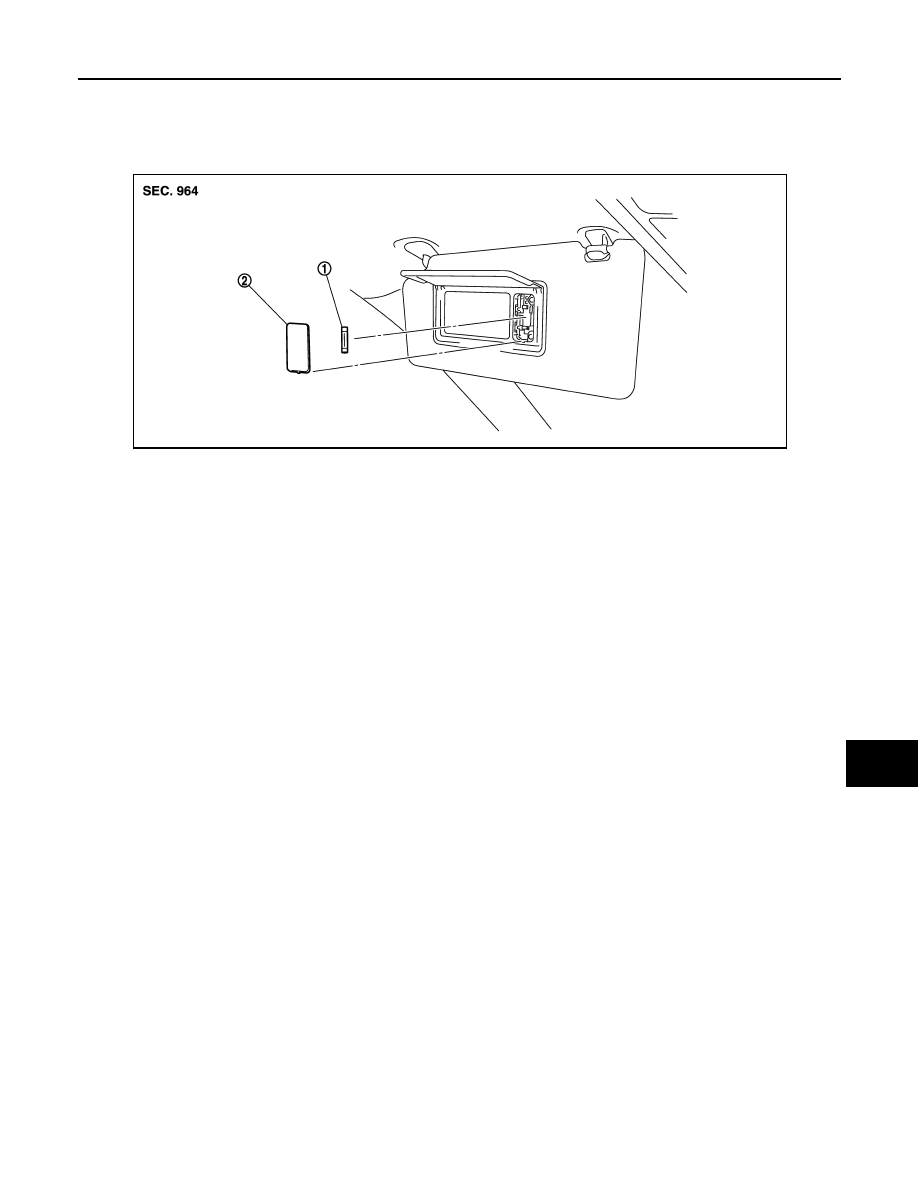

Exploded View

INFOID:0000000003295139

Replacement

INFOID:0000000003295140

CAUTION:

• Disconnect the battery negative terminal or remove the fuse.

• Never touch the glass of bulb directly by hand. Keep grease and other oily matters away from it.

• Never touch bulb by hand while it is lit or right after being turned off.

• Never leave bulb out of lamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bulb, be sure to replace it with new one.

VANITY MIRROR LAMP BULB

1.

Insert any appropriate tool into the gap between the lens. Remove the lens.

2.

Remove the bulb.

1.

Bulb

2.

Lens

JPLIA0988ZZ

Revision: 2008 October

2009 Murano