Nissan Murano Z51 (2008 year). Manual - part 235

PRECAUTIONS

HAC-235

< PRECAUTION >

[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

• Keep refrigerant away from open flames. Poisonous gas is produced if refrigerant burns.

• Refrigerant displaces oxygen, therefore be certain to work in well ventilated areas to prevent suffo-

cation.

• Never pressure test or leakage test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

Refrigerant Connection

INFOID:0000000003469383

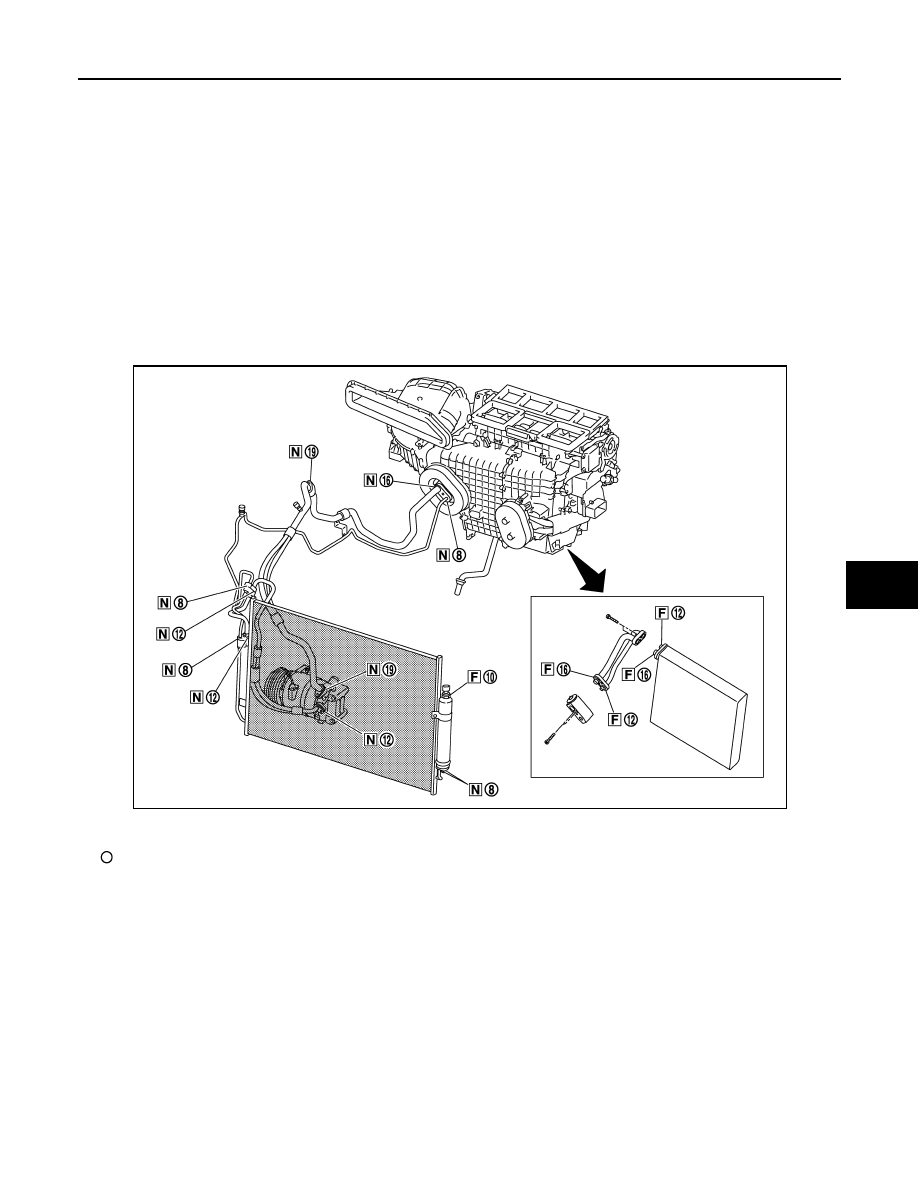

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to liquid tank

O-RING AND REFRIGERANT CONNECTION

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Never confuse O-

rings since they are not interchangeable. Refrigerant may leak at the connection if a wrong O-ring is

installed.

O-Ring Part Numbers and Specifications

F.

Former type refrigerant connection

N.

New type refrigerant connection

:

O-ring size

JPIIA0453ZZ

Revision: 2008 October

2009 Murano