Nissan Murano Z51 (2008 year). Manual - part 234

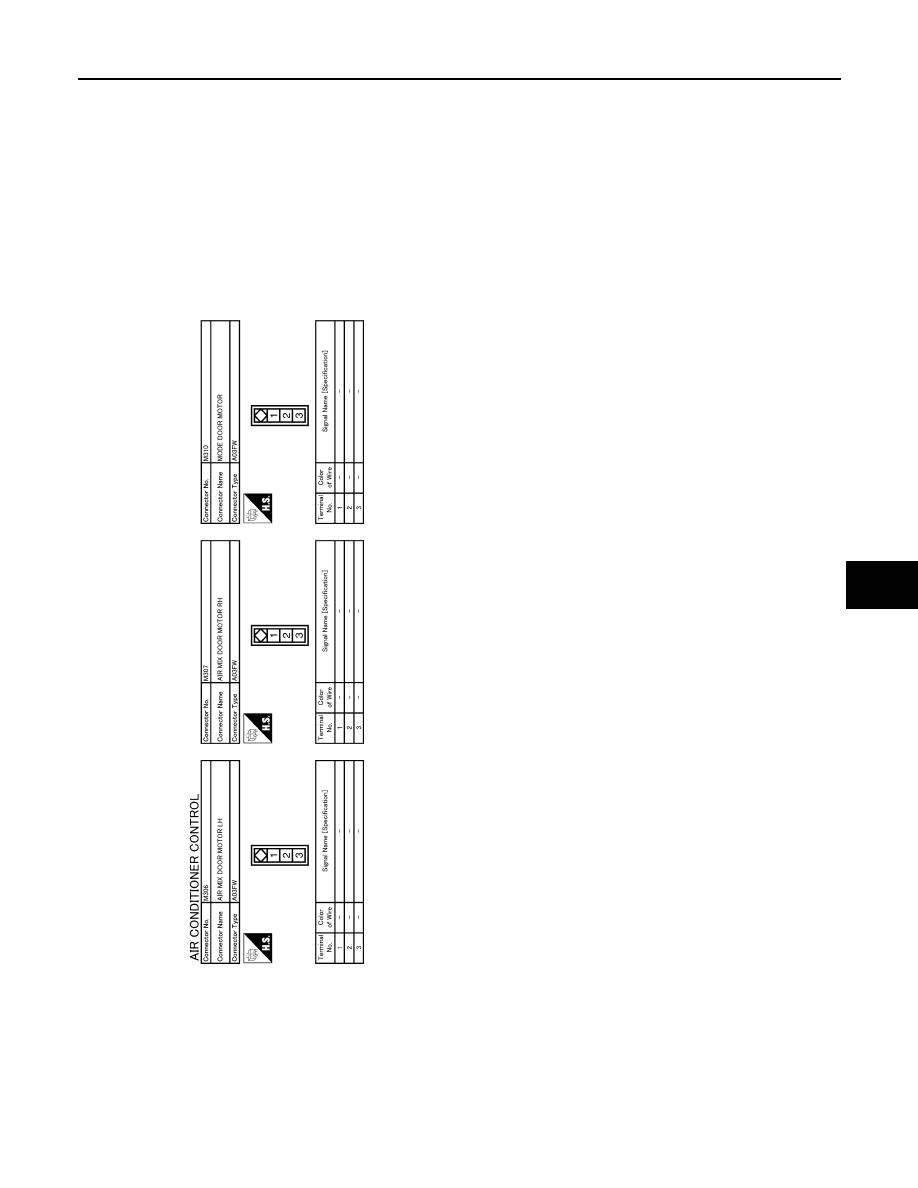

A/C AUTO AMP.

HAC-219

< ECU DIAGNOSIS >

[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

Fail-Safe

INFOID:0000000003469362

FAIL-SAFE FUNCTION

• If a communication error exists between the A/C auto amp., and the AV control unit and preset switch for 30

seconds or longer, air conditioner is controlled under the following conditions:

JCIWM0367GB

Revision: 2008 October

2009 Murano