Nissan Murano Z51 (2008 year). Manual - part 151

EC-232

< COMPONENT DIAGNOSIS >

[VQ35DE]

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

If it is difficult to start engine, the fuel injection system has a malfunction, too.

Crank engine while depressing accelerator pedal.

NOTE:

• When depressing accelerator pedal three-fourths (3/4) or more, the control system does not start the

engine. Do not depress accelerator pedal too much.

Does engine start?

YES

>> Go to

NO

>> Check exhaust and intake air leakage visually.

4.

PERFORM DTC CONFIRMATION PROCEDURE-II

1.

Keep engine idle for at least 10 minutes.

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> GO TO 5.

5.

PERFORM DTC CONFIRMATION PROCEDURE-III

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Start engine and drive the vehicle under similar conditions to (1st trip) Freeze Frame Data for 10 minutes.

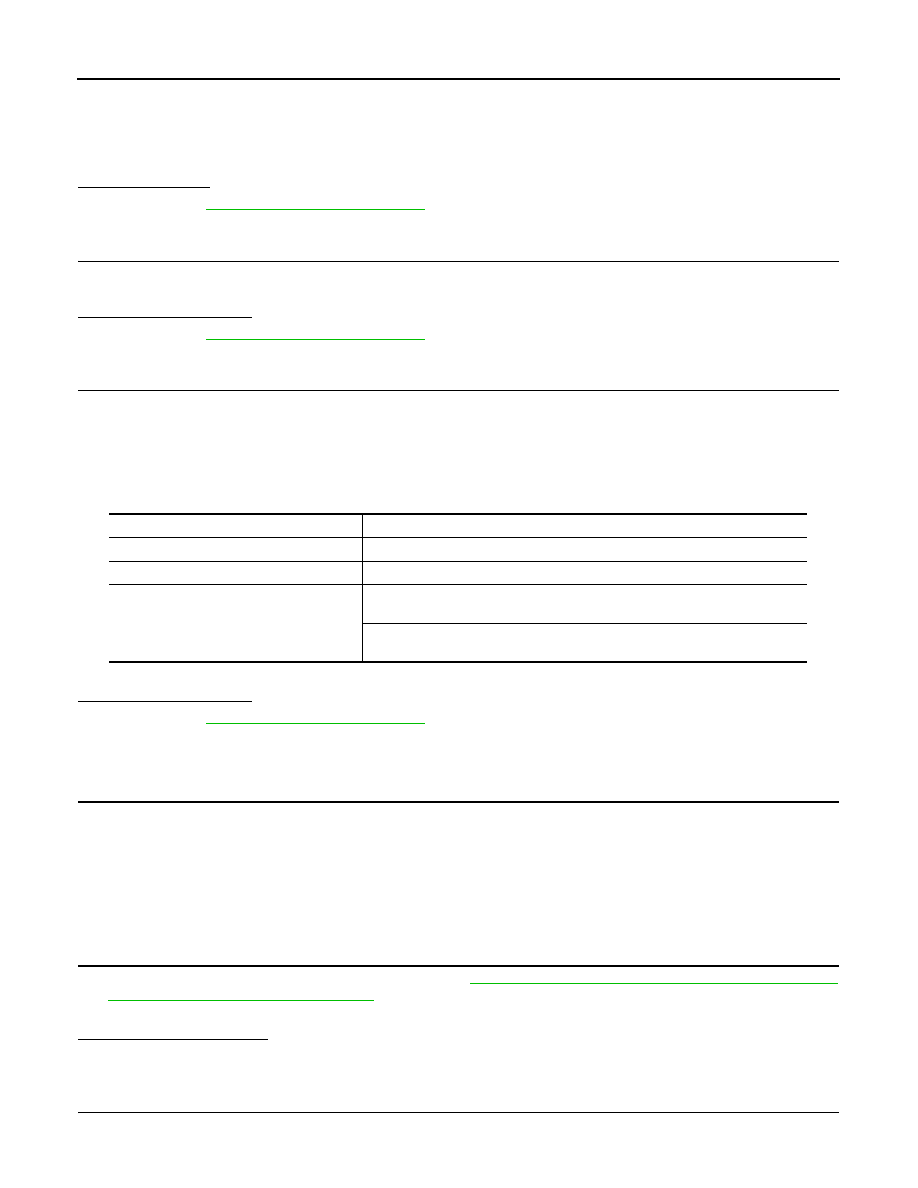

Refer to the table below.

Hold the accelerator pedal as steady as possible.

Similar conditions to (1st trip) Freeze Frame Data mean that the following conditions should be satisfied at

the same time.

3.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

TYPE B

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next test.

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Turn ignition switch ON.

3.

Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE-I

1.

Clear the mixture ratio self-learning value. Refer to

EC-19, "MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement"

.

2.

Start engine.

Is it difficult to start engine?

YES

>> GO TO 3.

NO

>> GO TO 4.

3.

RESTART ENGINE

If it is difficult to start engine, the fuel injection system has a malfunction, too.

Engine speed

Engine speed in the freeze frame data

±

400 rpm

Vehicle speed

Vehicle speed in the freeze frame data

±

10 km/h (6 MPH)

Basic fuel schedule

Basic fuel schedule in freeze frame data

×

(1

±

0.1)

Engine coolant temperature (T) condition

When the freeze frame data shows lower than 70

°

C (158

°

F),

T should be lower than 70

°

C (158

°

F).

When the freeze frame data shows higher than or equal to 70

°

C (158

°

F),

T should be higher than or equal to 70

°

C (158

°

F).

Revision: 2008 October

2009 Murano