Nissan Murano Z51 (2008 year). Manual - part 149

EC-200

< COMPONENT DIAGNOSIS >

[VQ35DE]

P0133, P0153 A/F SENSOR 1

>> Repair or replace malfunctioning part.

7.

PERFORM DTC CONFIRMATION PROCEDURE-IV

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Turn ignition switch ON.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1minute under no load.

5.

Let engine idle for 1 minute.

6.

Increase the engine speed up to between 4,000 and 5,000 rpm and maintain that speed for 10 seconds.

7.

Fully release accelerator pedal and then let engine idle for approximately 1 minute.

8.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000003387999

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E38. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

RETIGHTEN A/F SENSOR 1

Loosen and retighten the A/F sensor 1. Refer to

EM-34, "Removal and Installation"

.

>> GO TO 3.

3.

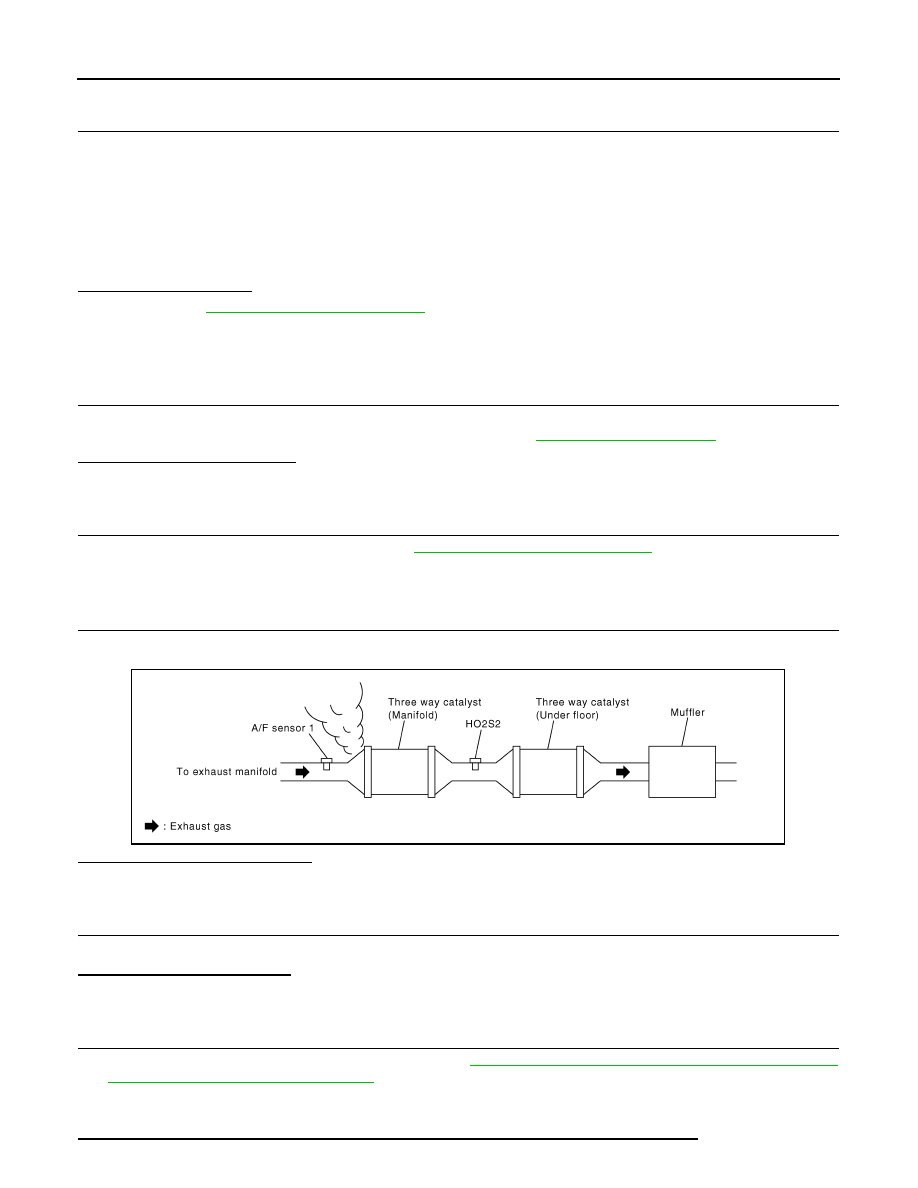

CHECK EXHAUST GAS LEAKAGE

1.

Start engine and run it at idle.

2.

Listen for an exhaust gas leakage before three way catalyst (manifold).

Is exhaust gas leakage detected?

YES

>> Repair or replace malfunctioning part.

NO

>> GO TO 4.

4.

CHECK FOR INTAKE AIR LEAKAGE

Listen for an intake air leakage after the mass air flow sensor.

Is intake air leakage detected?

YES

>> Repair or replace malfunctioning part.

NO

>> GO TO 5.

5.

CLEAR MIXTURE RATIO SELF-LEARNING VALUE

1.

Clear the mixture ratio self-learning value. Refer to

EC-19, "MIXTURE RATIO SELF-LEARNING VALUE

CLEAR : Special Repair Requirement"

.

2.

Run engine for at least 10 minutes at idle speed.

3.

Check 1st trip DTC.

Is the 1st trip DTC P0171, P0172, P0174 or P0175 detected? Is it difficult to start engine?

PBIB1216E

Revision: 2008 October

2009 Murano