Nissan Murano Z51 (2008 year). Manual - part 144

EC-120

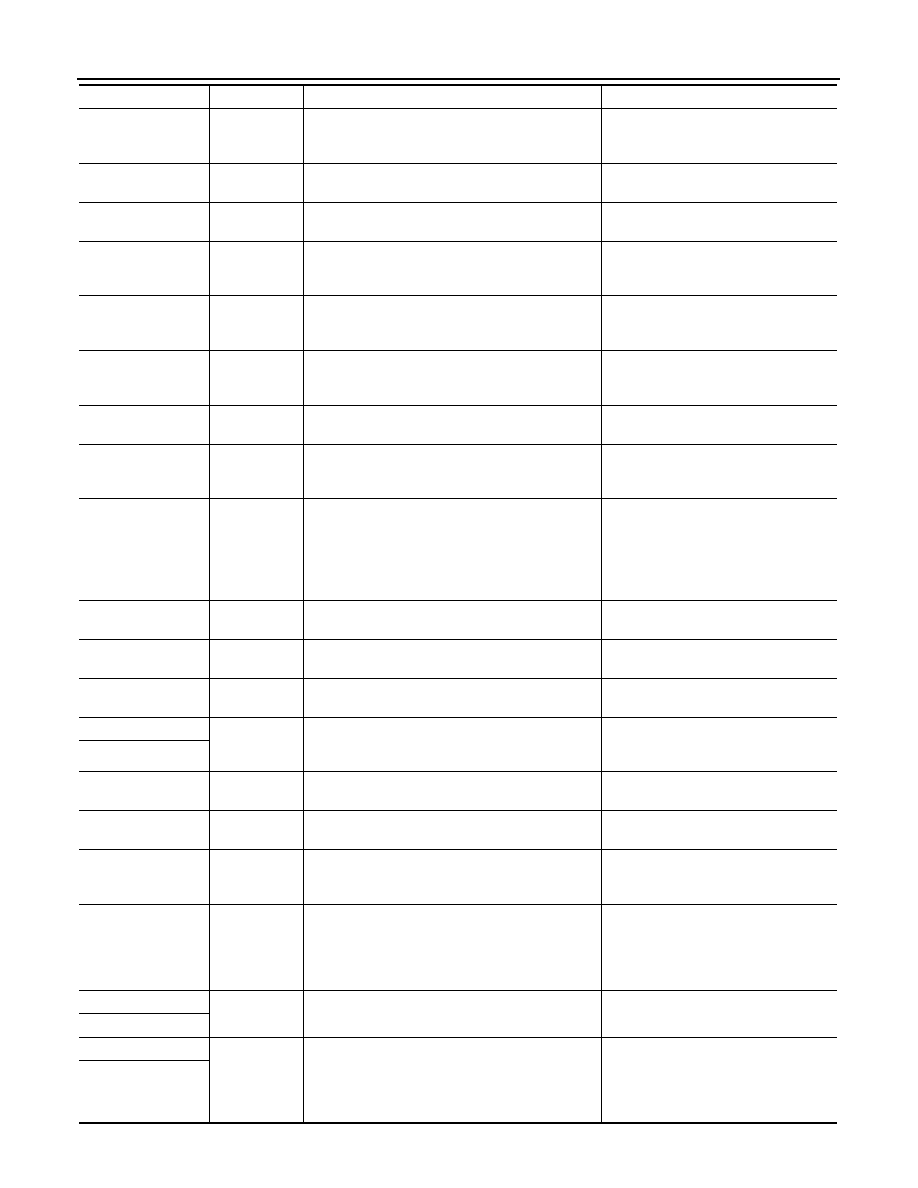

< FUNCTION DIAGNOSIS >

[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

INT/A TEMP SE

°

C or

°

F

• The intake air temperature (determined by the

signal voltage of the intake air temperature sen-

sor) is indicated.

EVAP SYS PRES

V

• The signal voltage of EVAP control system pres-

sure sensor is displayed.

FUEL LEVEL SE

V

• The signal voltage of the fuel level sensor is dis-

played.

START SIGNAL

ON/OFF

• Indicates start signal status [ON/OFF] computed

by the ECM according to the signals of engine

speed and battery voltage.

• After starting the engine, [OFF] is dis-

played regardless of the starter sig-

nal.

CLSD THL POS

ON/OFF

• Indicates idle position [ON/OFF] computed by

ECM according to the accelerator pedal position

sensor signal.

AIR COND SIG

ON/OFF

• Indicates [ON/OFF] condition of the air condition-

er switch as determined by the air conditioner sig-

nal.

P/N POSI SW

ON/OFF

• Indicates [ON/OFF] condition from the park/neu-

tral position (PNP) signal.

PW/ST SIGNAL

ON/OFF

• [ON/OFF] condition of the power steering system

(determined by the signal voltage of the power

steering pressure sensor) is indicated.

LOAD SIGNAL

ON/OFF

• Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW

ON/OFF

• Indicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW

ON/OFF

• Indicates [ON/OFF] condition from the heater fan

switch signal.

BRAKE SW

ON/OFF

• Indicates [ON/OFF] condition from the stop lamp

switch signal.

INJ PULSE-B1

msec

• Indicates the actual fuel injection pulse width

compensated by ECM according to the input sig-

nals.

• When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

IGN TIMING

BTDC

• Indicates the ignition timing computed by ECM

according to the input signals.

• When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE

%

• “Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW

g·m/s

• Indicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V

%

• Indicates the EVAP canister purge volume con-

trol solenoid valve control value computed by the

ECM according to the input signals.

• The opening becomes larger as the value in-

creases.

INT/V TIM (B1)

°

CA

• Indicates [

°

CA] of intake camshaft advance an-

gle.

INT/V TIM (B2)

INT/V SOL-B1

%

• The control value of the intake valve timing con-

trol solenoid valve (determined by ECM accord-

ing to the input signals) is indicated.

• The advance angle becomes larger as the value

increases.

INT/V SOL-B2

Monitored item

Unit

Description

Remarks

Revision: 2008 October

2009 Murano