Nissan Murano Z51 (2008 year). Manual - part 138

EC-24

< FUNCTION DIAGNOSIS >

[VQ35DE]

ENGINE CONTROL SYSTEM

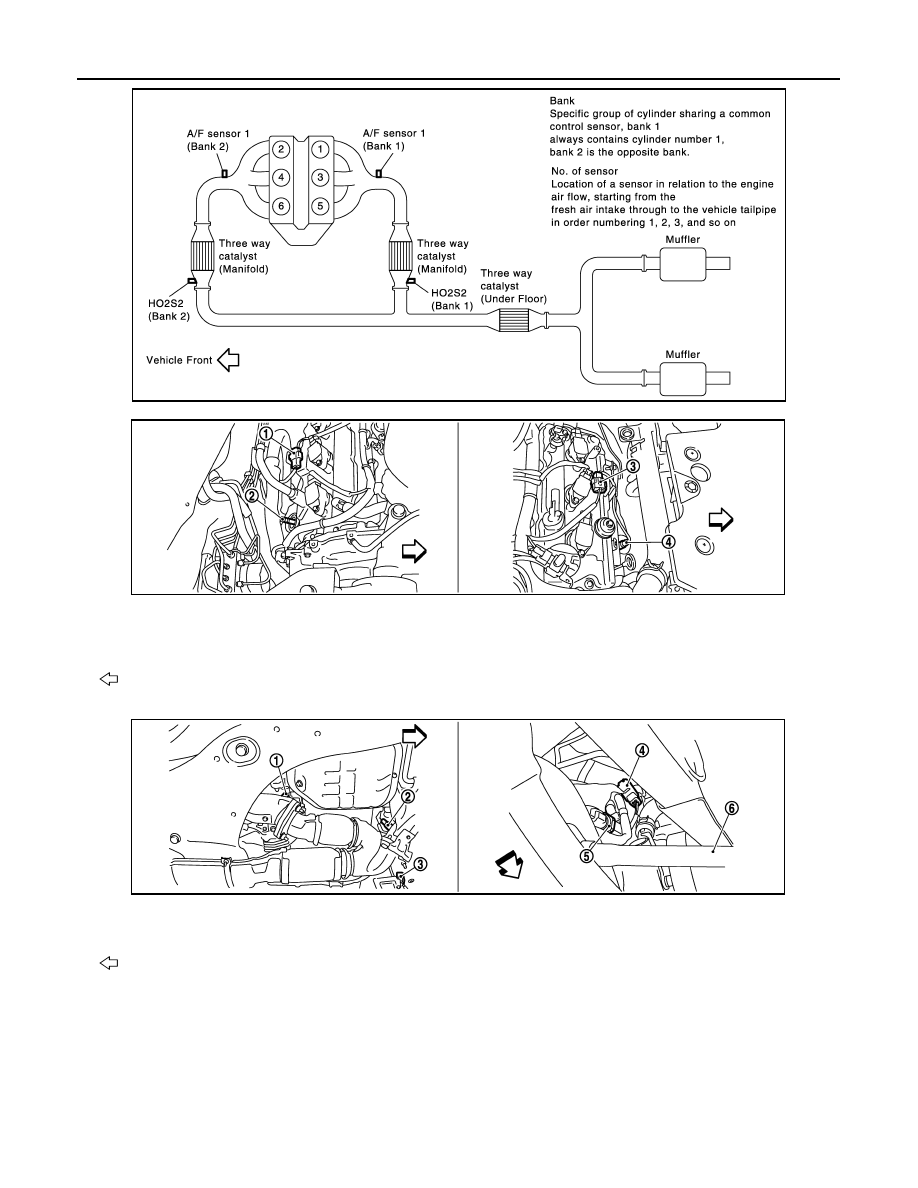

JMBIA1832GB

1.

A/F sensor 1 (bank 1) harness con-

nector

2.

A/F sensor 1 (bank 1)

3.

A/F sensor 1 (bank 2) harness con-

nector

4.

A/F sensor 1 (bank 2)

: Vehicle front

1.

HO2S2 (bank 1)

2.

HO2S2 (bank 2)

3.

HO2S2 (bank 2) harness connector

4.

HO2S2 (bank 1) harness connector

5.

Power steering pressure sensor

6.

Drive shaft (RH)

: Vehicle front

JMBIA1116ZZ

JMBIA1117ZZ

Revision: 2008 October

2009 Murano