Nissan Murano Z51 (2008 year). Manual - part 137

EC-8

< BASIC INSPECTION >

[VQ35DE]

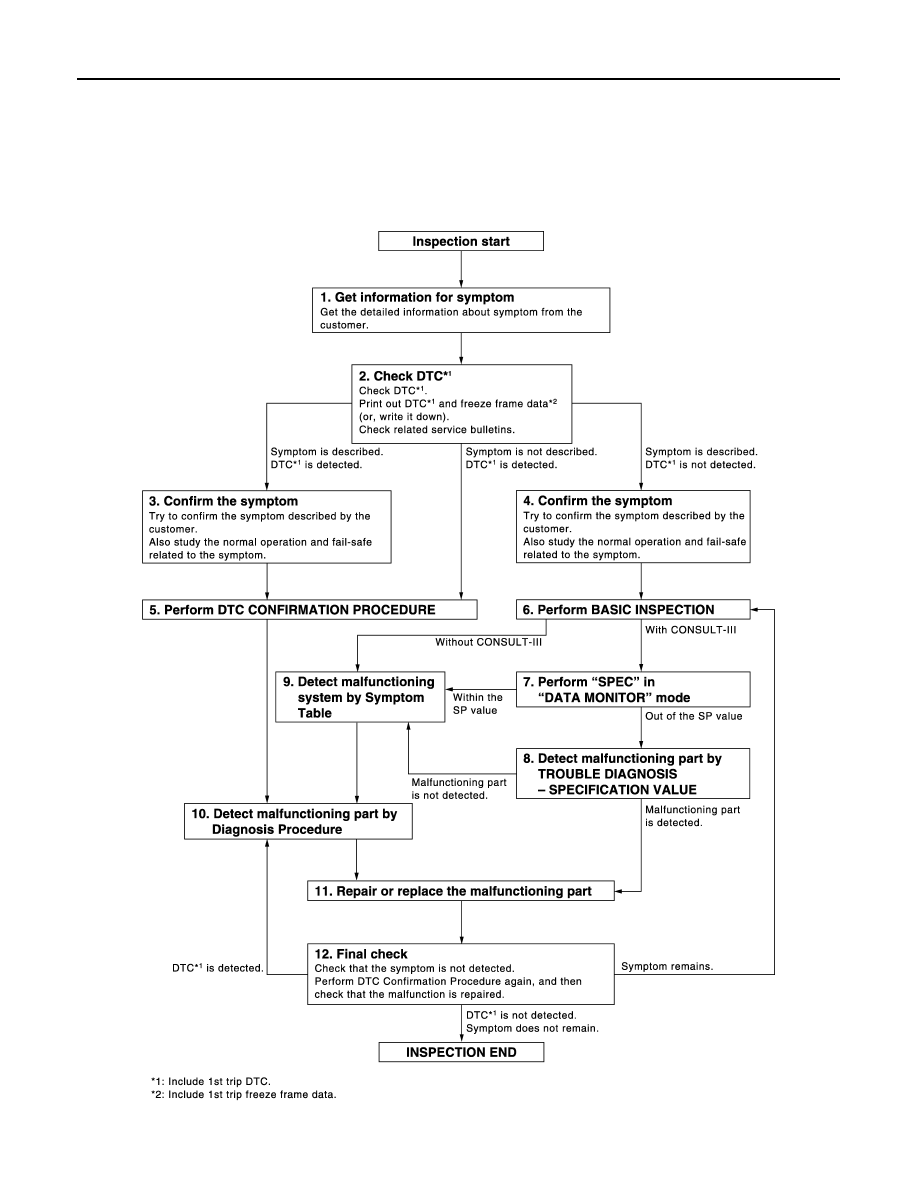

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000003387866

OVERALL SEQUENCE

DETAILED FLOW

JMBIA1416GB

Revision: 2008 October

2009 Murano