Nissan Murano Z51 (2008 year). Manual - part 75

BRC-40

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace damaged parts.

6.

CHECK DATA MONITOR

1.

Turn the ignition switch OFF.

2.

Connect each wheel sensor connector.

3.

Check wheel sensor signal. Refer to

BRC-40, "Component Inspection"

Is the inspection result normal?

YES

>> Replace ABS actuator and electric unit (control unit).

NO

>> Repair or replace damaged parts.

Component Inspection

INFOID:0000000003390266

1.

CHECK DATA MONITOR

On “DATA MONITOR”, select “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR”, and “RR RH SEN-

SOR”, and check the vehicle speed.

NOTE:

Confirm tire pressure is normal.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to diagnosis procedure. Refer to

.

Special Repair Requirement

INFOID:0000000003390263

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION, CALIBRATION OF YAW RATE/

SIDE/DECEL G SENSOR AND CALIBRATION OF PRESSURE SENSOR

After removing/replacing an ABS actuator and electric unit (control unit), be sure to perform the following pro-

cedure.

• Adjustment of steering angle sensor neutral position: Refer to

BRC-9, "ADJUSTMENT OF STEERING

ANGLE SENSOR NEUTRAL POSITION : Description"

.

• Calibration of yaw rate/side/decel G sensor: Refer to

BRC-10, "CALIBRATION OF YAW RATE/SIDE/DECEL

.

• Calibration of pressure sensor: Refer to

BRC-11, "CALIBRATION OF PRESSURE SENSOR : Description"

>> END

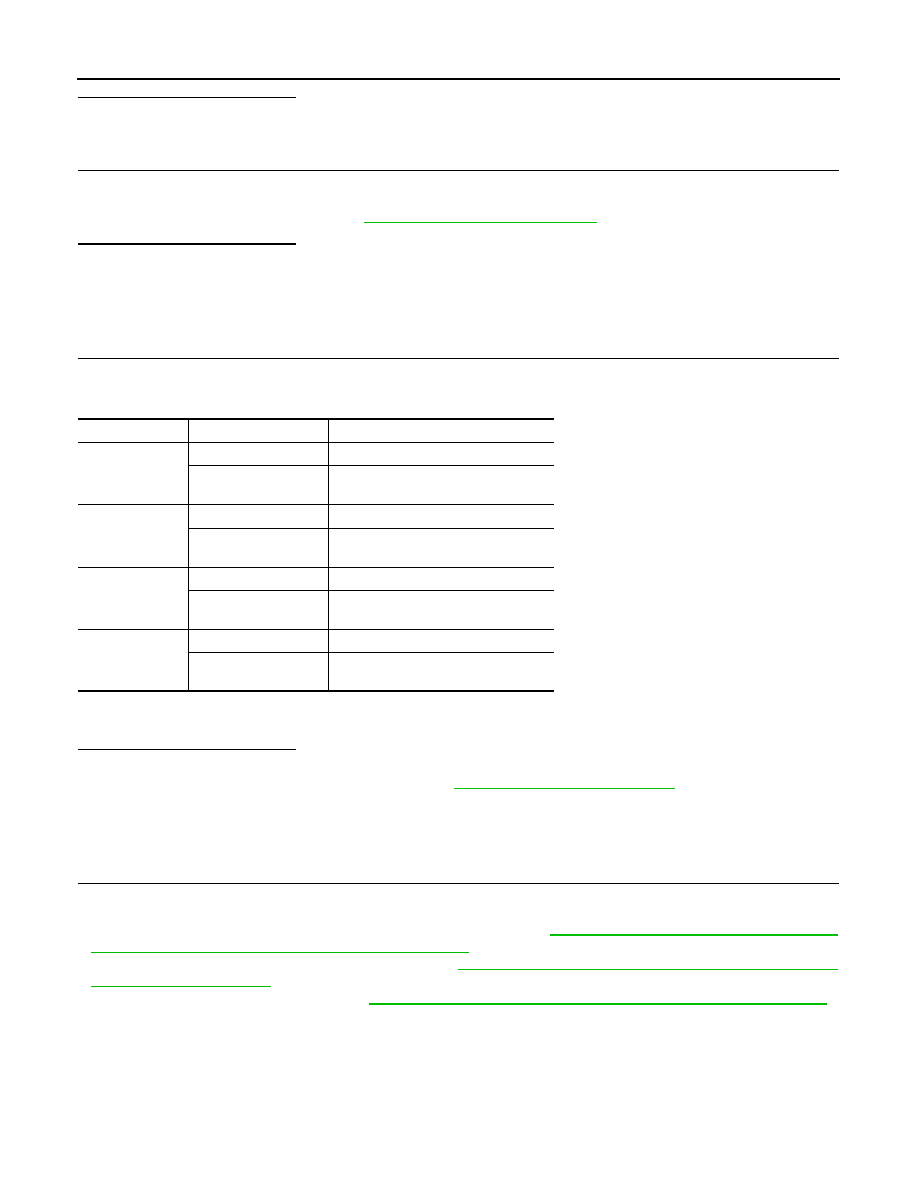

Wheel sensor

Condition

Vehicle speed (DATA MONITOR)

FR LH SENSOR

Vehicle stopped

0 [km/h (MPH)]

Vehicle running (Note)

Nearly matches the speedometer dis-

play (

±

10% or less)

FR RH SENSOR

Vehicle stopped

0 [km/h (MPH)]

Vehicle running (Note)

Nearly matches the speedometer dis-

play (

±

10% or less)

RR LH SENSOR

Vehicle stopped

0 [km/h (MPH)]

Vehicle running (Note)

Nearly matches the speedometer dis-

play (

±

10% or less)

RR RH SENSOR

Vehicle stopped

0 [km/h (MPH)]

Vehicle running (Note)

Nearly matches the speedometer dis-

play (

±

10% or less)

Revision: 2008 October

2009 Murano