Infiniti FX35, FX50 (S51). Manual - part 981

EM-224

< UNIT DISASSEMBLY AND ASSEMBLY >

[VK50VE]

TIMING CHAIN

a.

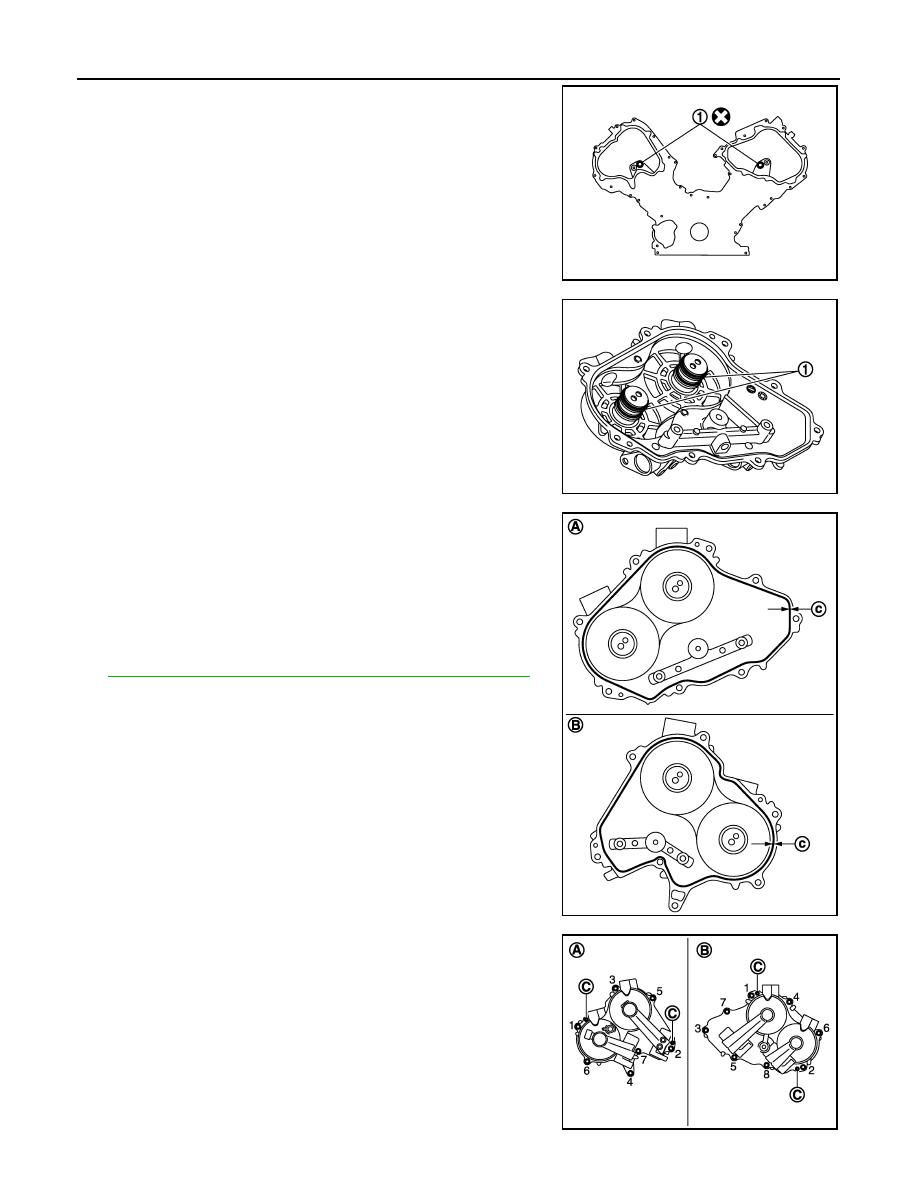

Install new O-rings (1) on front cover.

b.

Install new seal rings (1) in shaft grooves.

CAUTION:

When replacing seal ring, replace all rings with new ones.

c.

Apply a continuous bead of liquid gasket with tube presser

(commercial service tool) to valve timing control covers as

shown in the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-16, "Recommended Chemical Products and Sealants"

.

d.

Being careful not to move seal ring from the installation groove,

align dowel pins on front cover with dowel pin holes (C) to install

valve timing control covers.

e.

Tighten mounting bolts in numerical order as shown in the fig-

ure.

JPBIA2117ZZ

JPBIA2103ZZ

A

: Bank 1

B

: Bank 2

c

:

φ

3.4 - 4.4 mm (0.134 - 0.173 in)

JPBIA2104ZZ

A

: Bank 2

B

: Bank 1

JPBIA2118ZZ