Infiniti FX35, FX50 (S51). Manual - part 977

EM-208

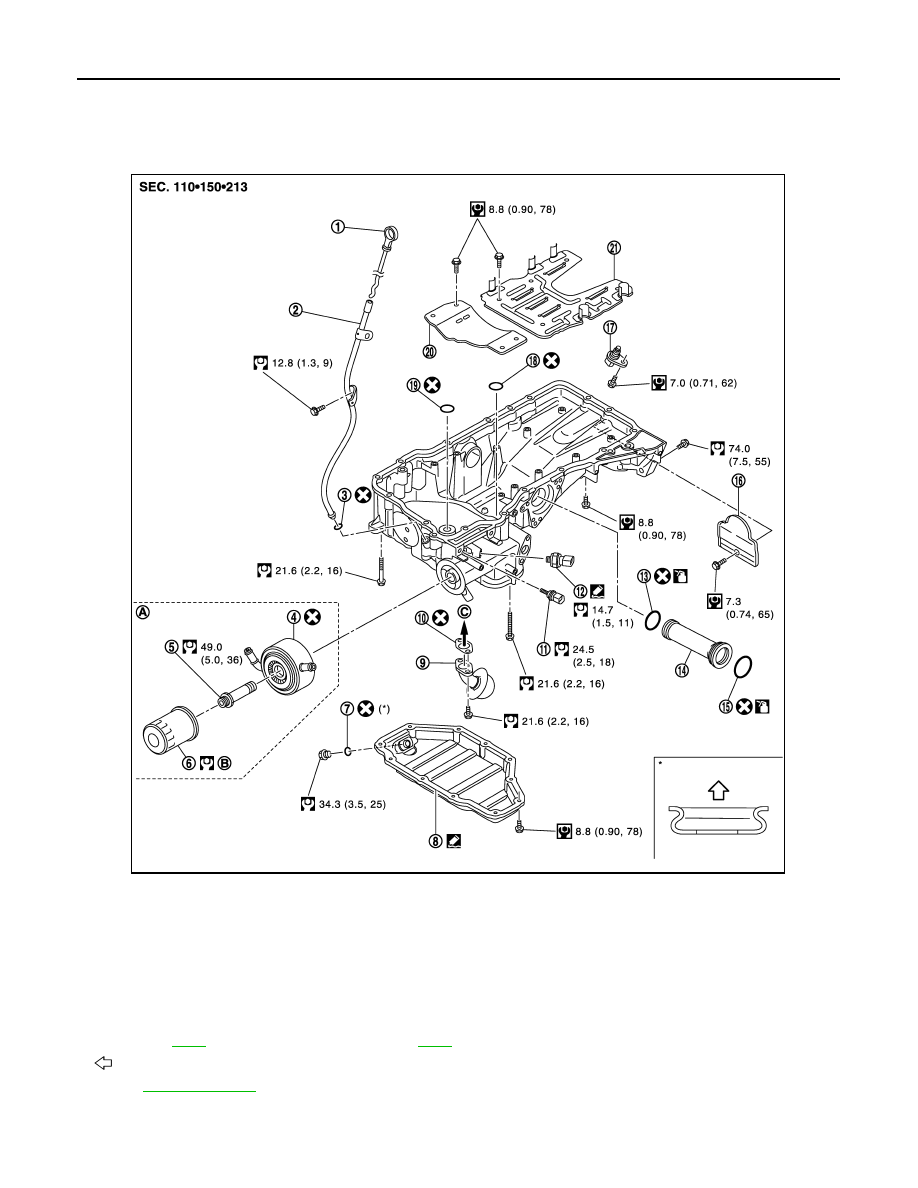

< UNIT DISASSEMBLY AND ASSEMBLY >

[VK50VE]

OIL PAN (UPPER)

OIL PAN (UPPER)

Exploded View

INFOID:0000000005245247

1.

Oil level gauge

2.

Oil level gauge guide

3.

O-ring

4.

Oil cooler

5.

Connector bolt

6.

Oil filter

7.

Drain plug washer

8.

Oil pan (lower)

9.

Oil strainer

10. Gasket

11.

Oil temperature sensor

12. Oil pressure switch

13. O-ring

14. Axle pipe

15. O-ring

16. Rear plate cover

17. Crankshaft position sensor (POS)

18. O-ring

19. O-ring

20. Baffle plate

21. Baffle plate

A.

Refer to

B.

Refer to

C.

Oil pump side

: Oil pan side

for symbols in the figure.

JPBIA2088GB