Infiniti FX35, FX50 (S51). Manual - part 975

EM-200

< UNIT REMOVAL AND INSTALLATION >

[VK50VE]

ENGINE ASSEMBLY

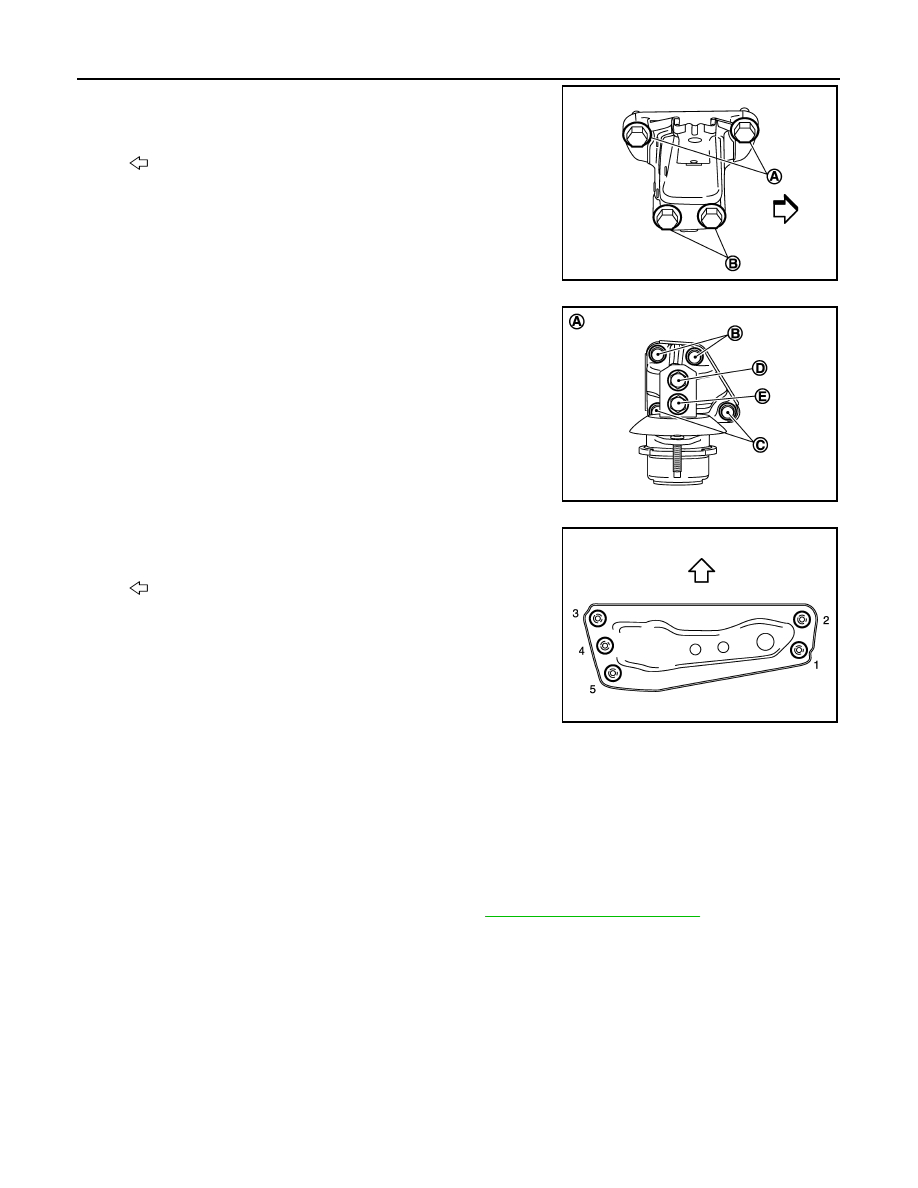

• When installing engine mounting bracket (RH and LH) on cylinder

block, tighten two upper bolts (A) first. Then tighten two lower bolts

(B).

NOTE:

This figure shows an example of bank 2.

• When installing engine mounting bracket (rear) on transfer, tighten

two upper bolts (B) first. Then tighten two lower bolts (C).

• When installing engine mounting insulator (rear) on engine mount-

ing bracket (rear), tighten upper bolts (D) first. Then tighten lower

bolts (E).

• Tighten rear engine mounting member bolts in numerical order as

shown in the figure.

• Check that all engine mounting insulators are seated properly, then tighten mounting nuts and bolts.

Inspection

INFOID:0000000005245240

INSPECTION AFTER INSTALLATION

Inspection for Leakage

The following are procedures for checking fluid leakage, lubricant leakage.

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If any are less than the

required quantity, fill them to the specified level. Refer to

MA-12, "Fluids and Lubricants"

.

• Follow the procedure below to check for fuel leakage.

- Turn ignition switch to the “ON” position (with engine stopped). With fuel pressure applied to fuel piping,

check for fuel leakage at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate a malfunction. The

noise will stop after hydraulic pressure rises.

• Warm up engine thoroughly to check that there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

: Engine front

JPBIA2096ZZ

A

: Rear view

JPBIA2464ZZ

: Vehicle front

JPBIA2463ZZ