Infiniti FX35, FX50 (S51). Manual - part 956

EM-124

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ35HR]

CYLINDER BLOCK

• Check the piston ring side clearance. Refer to

.

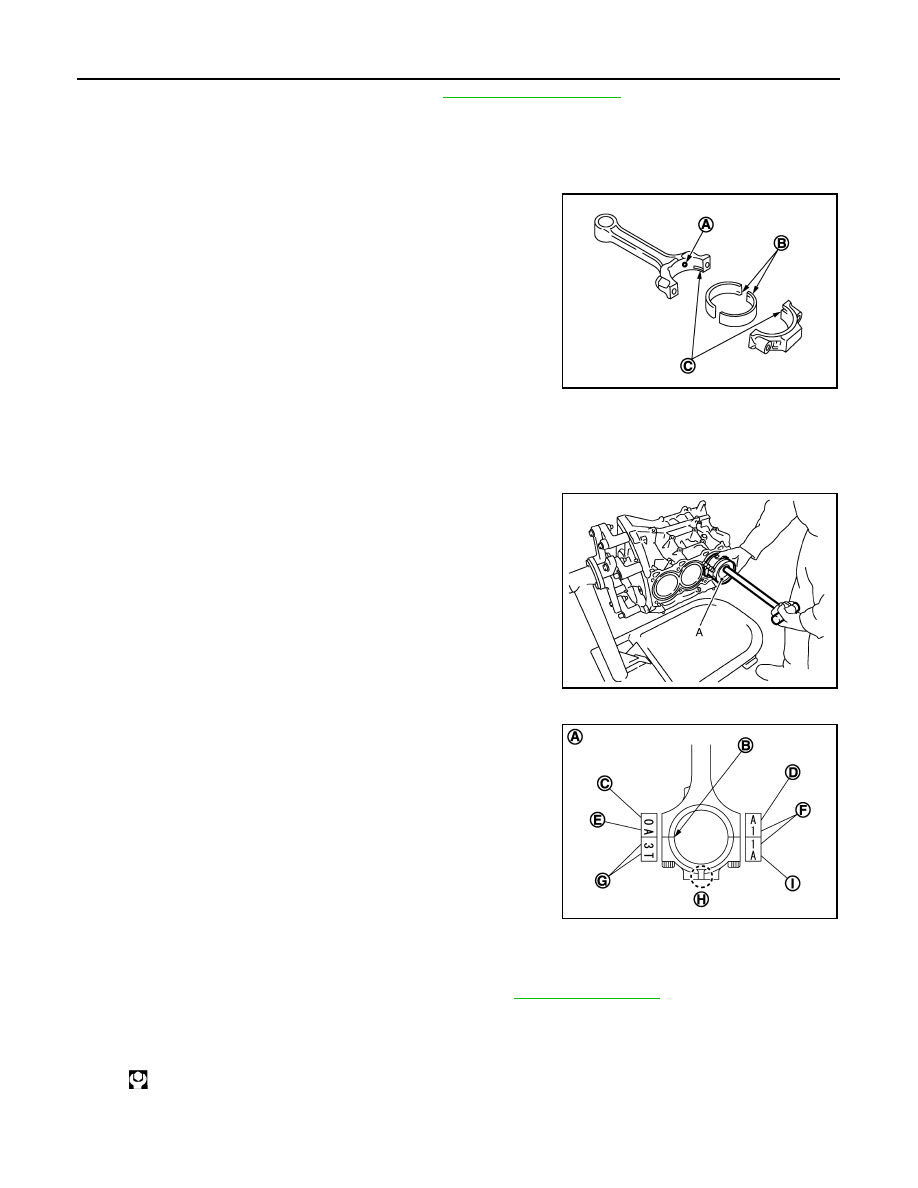

11. Install connecting rod bearings to connecting rod and connecting rod bearing cap.

CAUTION:

Be careful not to drop connecting rod bearing, and to scratch the surface.

• Before installing connecting rod bearings, apply engine oil to the bearing surface (inside). Do not apply

engine oil to the back surface, but thoroughly clean it.

• When installing, align connecting rod bearing stopper protru-

sion (B) with cutout (C) of connecting rods and connecting rod

bearing caps to install.

• Ensure the oil hole (A) on connecting rod and that on the cor-

responding bearing are aligned.

12. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be installed onto the bottom dead center.

• Apply engine oil sufficiently to the cylinder bore, piston and crankshaft pin journal.

• Match the cylinder position with the cylinder number on connecting rod to install.

• Be sure that front mark on piston crown is facing front of engine.

• Using a piston ring compressor [SST: EM03470000 (J-8037)]

(A) or suitable tool, install piston with the front mark on the pis-

ton crown facing the front of the engine.

CAUTION:

Be careful not to damage the cylinder wall and crankshaft

pin, resulting from an interference of the connecting rod big

end.

13. Install connecting rod bearing cap.

• Match the stamped cylinder number marks on connecting rod

with those on connecting rod bearing cap to install.

• Be sure that front mark (H) on connecting rod bearing cap is facing front of the engine.

14. Tighten connecting rod bolt as per the following:

a.

Inspect the outer diameter of connecting rod bolt. Refer to

.

b.

Apply engine oil to the threads and seats of connecting rod bolts.

c.

Tighten connecting rod bolts.

d.

Completely loosen connecting rod bolts.

JPBIA0206ZZ

JPBIA0207ZZ

A

: Sample codes

B

: Bearing stopper groove

C

: Small-end diameter grade

D

: Big-end diameter grade

E

: Weight grade

F

: Cylinder No.

G

: Management code

I

: Management code

: 28.4 N·m (2.9 kg-m, 21 ft-lb)

JPBIA0208ZZ