Infiniti FX35, FX50 (S51). Manual - part 935

EM-40

< REMOVAL AND INSTALLATION >

[VQ35HR]

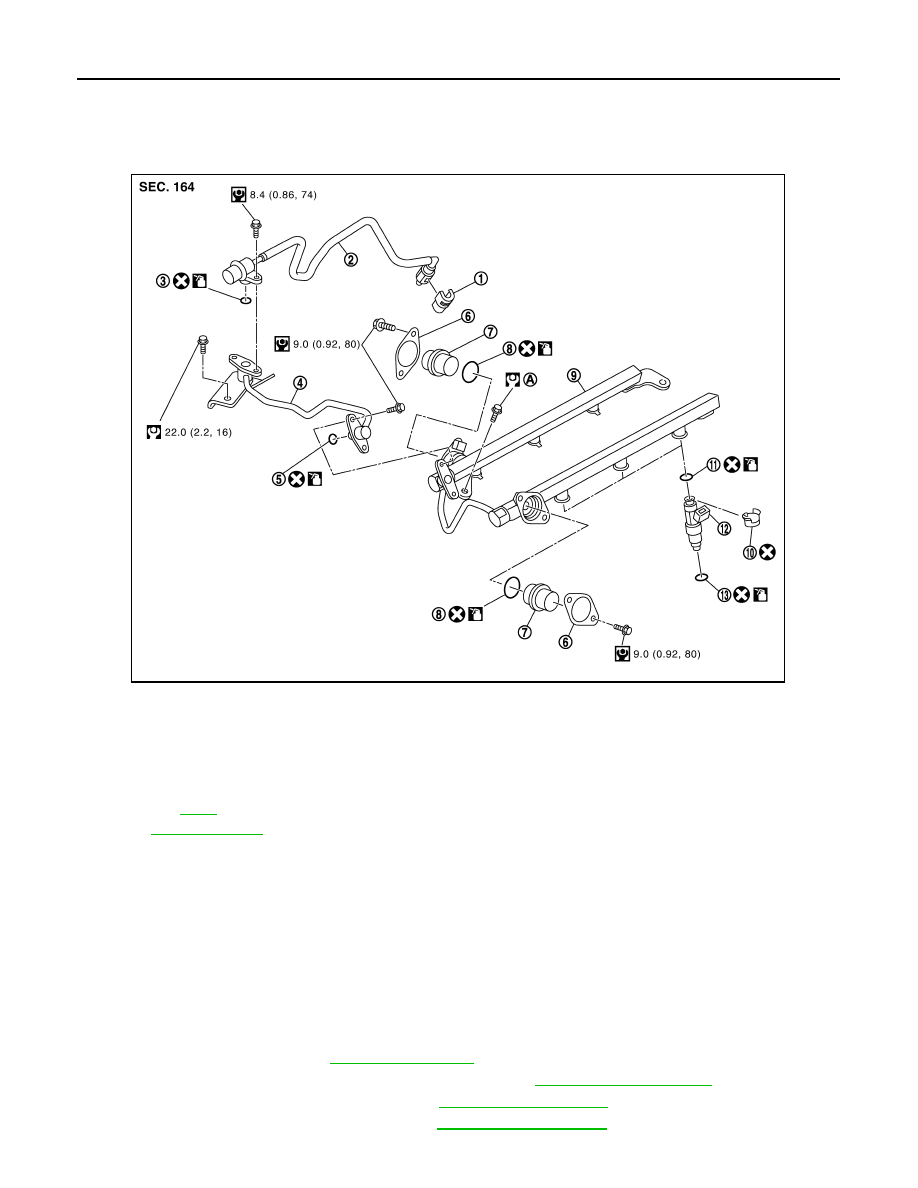

FUEL INJECTOR AND FUEL TUBE

FUEL INJECTOR AND FUEL TUBE

Exploded View

INFOID:0000000005245138

CAUTION:

Never remove or disassemble parts unless instructed as shown in the figure.

Removal and Installation

INFOID:0000000005245139

REMOVAL

WARNING:

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO

2

fire extinguisher.

• Never smoke while servicing fuel system. Keep open flames and sparks away from the work area.

• Never drain engine coolant when the engine is hot to avoid the danger of being scalded.

1.

Release fuel pressure. Refer to

.

2.

Disconnect battery cable from the negative terminal. Refer to

.

3.

Remove engine cover with power tool. Refer to

.

4.

Remove air cleaner case and air duct. Refer to

1.

Quick connector cap

2.

Fuel feed hose (with damper)

3.

O-ring

4.

Fuel sub tube

5.

O-ring

6.

Fuel damper cap

7.

Fuel damper

8.

O-ring

9.

Fuel tube

10. Clip

11. O-ring (black)

12. Fuel injector

13. O-ring (green)

A.

Refer to

Refer to

for symbols in the figure.

JPBIA1708GB