Infiniti FX35, FX50 (S51). Manual - part 866

P1226, P1235 TP SENSOR

EC-1005

< DTC/CIRCUIT DIAGNOSIS >

[VK50VE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

3.

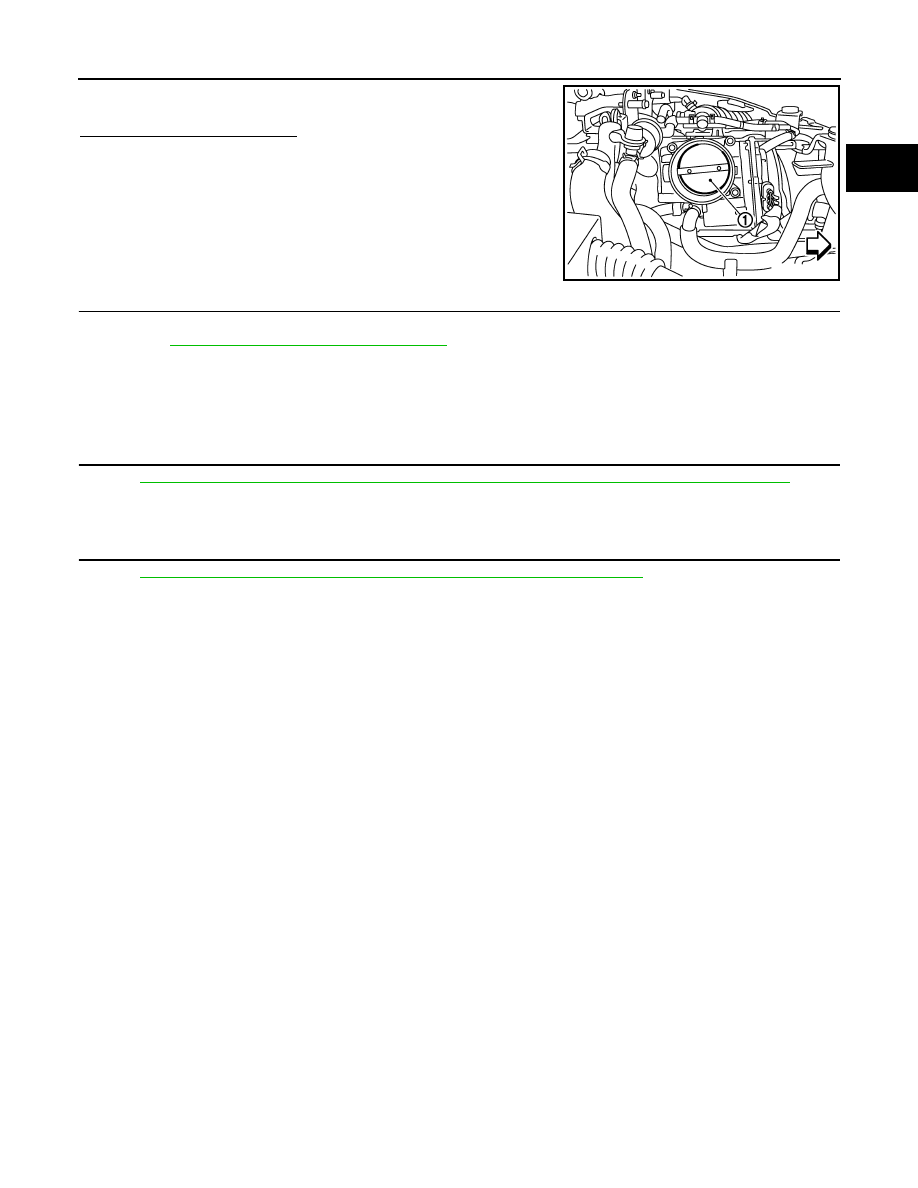

Check that no foreign matter is caught between the throttle valve

(1) and the housing.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Remove the foreign matter and clean the electric throttle

control actuator inside.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace malfunctioning electric throttle control actuator.

2.

EC-1005, "Special Repair Requirement"

.

>> INSPECTION END

Special Repair Requirement

INFOID:0000000005237489

1.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

EC-581, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 2.

2.

PERFORM IDLE AIR VOLUME LEARNING

EC-582, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

>> END

JMBIA1556ZZ