Infiniti FX35, FX50 (S51). Manual - part 842

P0447 EVAP CANISTER VENT CONTROL VALVE

EC-909

< DTC/CIRCUIT DIAGNOSIS >

[VK50VE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Clean the rubber tube using an air blower.

8.

CHECK EVAP CANISTER VENT CONTROL VALVE

EC-909, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace EVAP canister vent control valve.

9.

CHECK INTERMITTENT INCIDENT

GI-36, "Intermittent Incident"

.

>> INSPECTION END

Component Inspection

INFOID:0000000005237379

1.

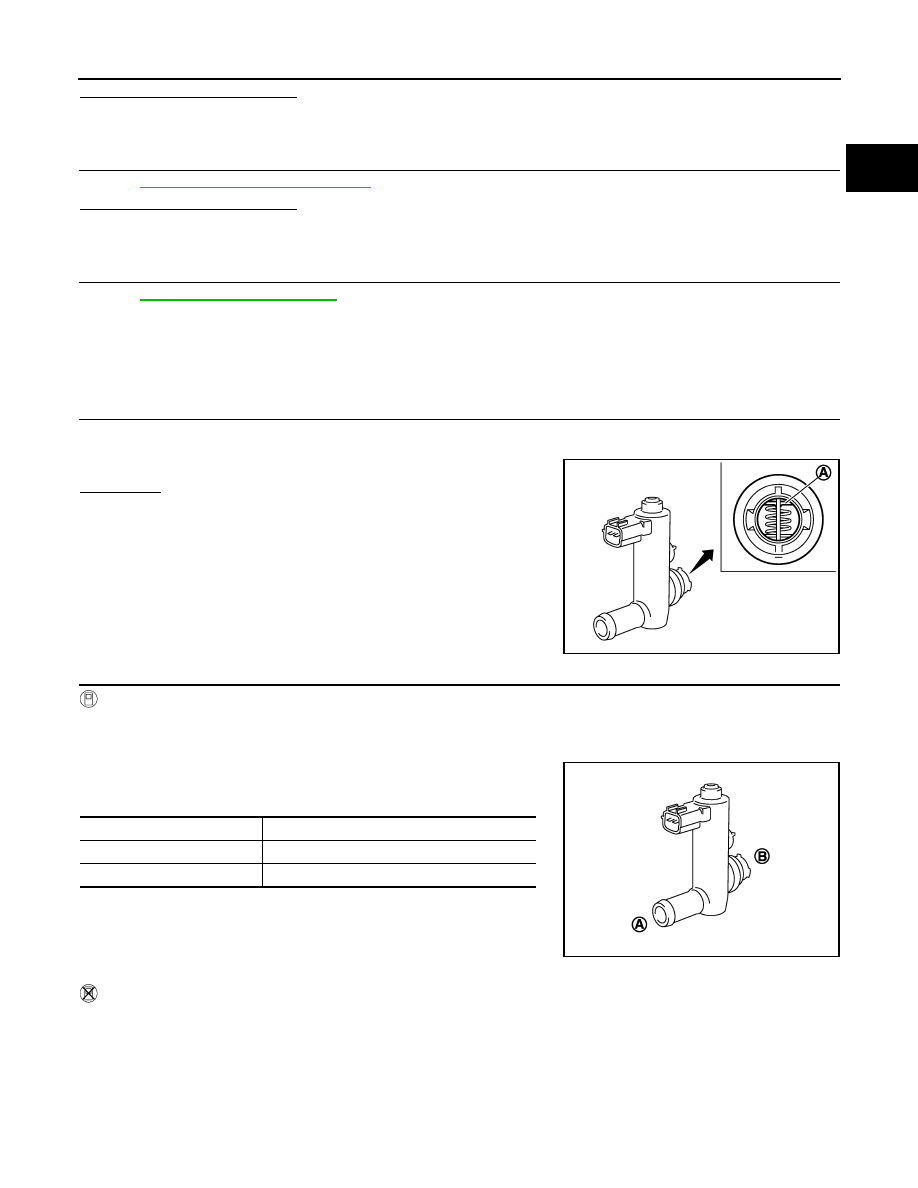

CHECK EVAP CANISTER VENT CONTROL VALVE-I

1.

Turn ignition switch OFF.

2.

Remove EVAP canister vent control valve from EVAP canister.

3.

Check portion (A) of EVAP canister vent control valve for rust.

Is it rusted?

YES

>> Replace EVAP canister vent control valve

NO

>> GO TO 2.

2.

CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT-III

1.

Reconnect harness connectors disconnected.

2.

Turn ignition switch ON.

3.

Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

4.

Check air passage continuity and operation delay time.

Check that new O-ring is installed properly.

Operation takes less than 1 second.

Without CONSULT-III

1.

Disconnect EVAP canister vent control valve harness connector.

2.

Check air passage continuity and operation delay time under the following conditions.

Check that new O-ring is installed properly.

JMBIA0168ZZ

VENT CONTROL/V Condition

Air passage continuity between (A) and (B)

ON

Not existed

OFF

Existed

JMBIA0169ZZ