Infiniti FX35, FX50 (S51). Manual - part 670

P0138, P0158 HO2S2

EC-221

< DTC/CIRCUIT DIAGNOSIS >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0138, P0158 HO2S2

Description

INFOID:0000000005236824

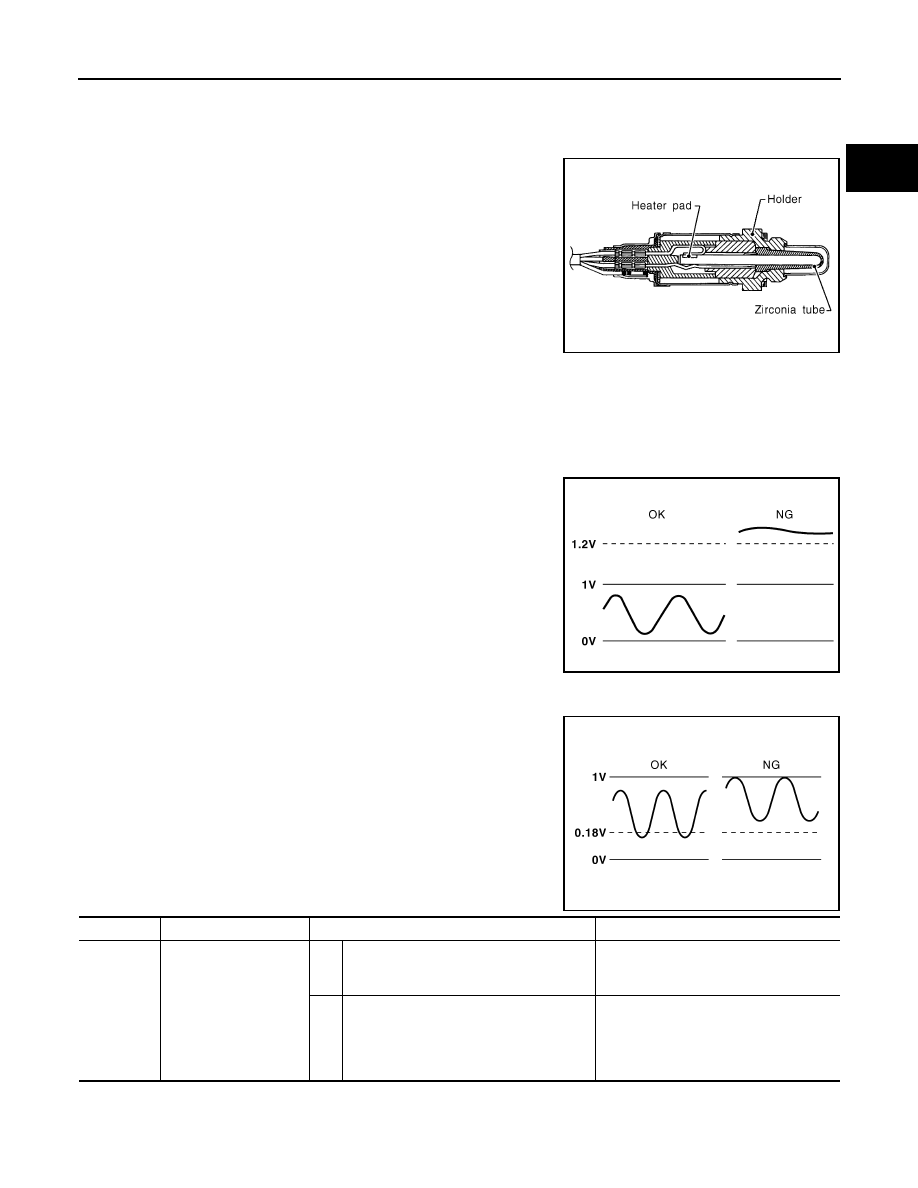

The heated oxygen sensor 2, after three way catalyst 1, monitors the

oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1 V in richer conditions to 0 V in leaner con-

ditions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

DTC Logic

INFOID:0000000005236825

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capacity of the three way catalyst 1 causes the longer switching time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the voltage is unusually high during various driving condi-

tions such as fuel cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the minimum voltage of sensor is sufficiently low during var-

ious driving conditions such as fuel cut.

SEF327R

PBIB1848E

PBIB2376E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0138

Heated oxygen sensor 2

(bank 1) circuit high volt-

age

A)

An excessively high voltage from the sen-

sor is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

B)

The minimum voltage from the sensor is

not reached to the specified voltage.

• Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector