Infiniti FX35, FX50 (S51). Manual - part 287

BRM-26

< REMOVAL AND INSTALLATION >

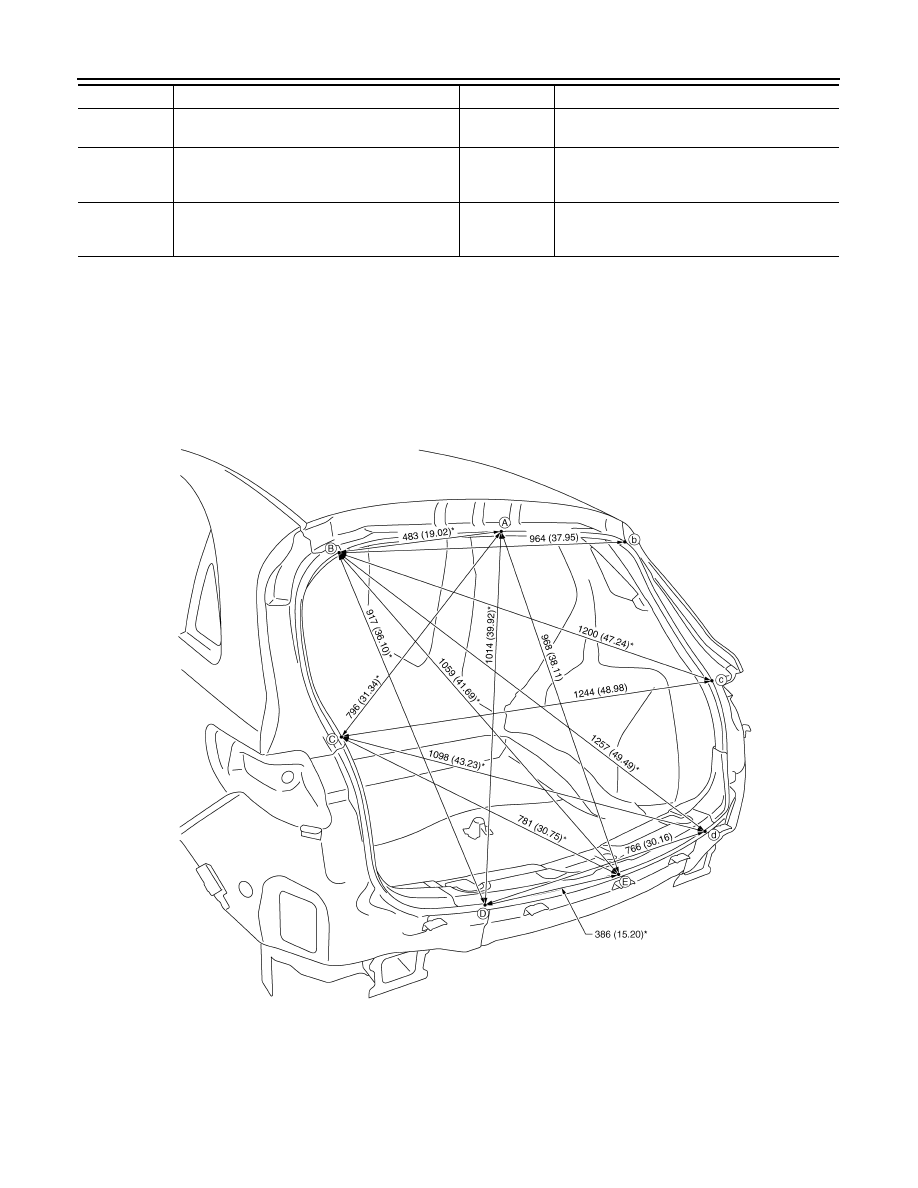

BODY ALIGNMENT

Rear Body

INFOID:0000000005248957

Measurement

Dimensions marked with

″

*

″

indicate symmetrically identical dimensions on both the right and left hand of the

vehicle.

Measurement Points

C, c

Front pillar joggle

T

Rear seat crossmember reinforcement hole cen-

ter of center positioning mark

φ

5 (0.20)

D, d, E, e, F, f,

G, g

Front pillar indent

U, u, V, v, W,

w, X, x

Door hinge installing hole center

U, u, V, v, X, x:

φ

12 (0.47)

W, w:

φ

9 (0.35)

H, h, J, j, K, k,

M, m, N, n, O,

o

Center pillar indent

Point

Material

Point

Material

Unit: mm (in)

JSKIA0667GB