Content .. 1940 1941 1942 1943 ..

Infiniti FX35, FX50 (S51). Manual - part 1942

ROAD WHEEL

WT-71

< PERIODIC MAINTENANCE >

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

PERIODIC MAINTENANCE

ROAD WHEEL

Adjustment

INFOID:0000000005243136

BALANCING WHEELS (BONDING WEIGHT TYPE)

Preparation Before Adjustment

Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

• Be careful not to scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting, select

and adjust a drive-in weight mode suitable for road wheels.

1.

Set road wheel on tire balance machine using the center hole as a guide. Start the tire balance machine.

2.

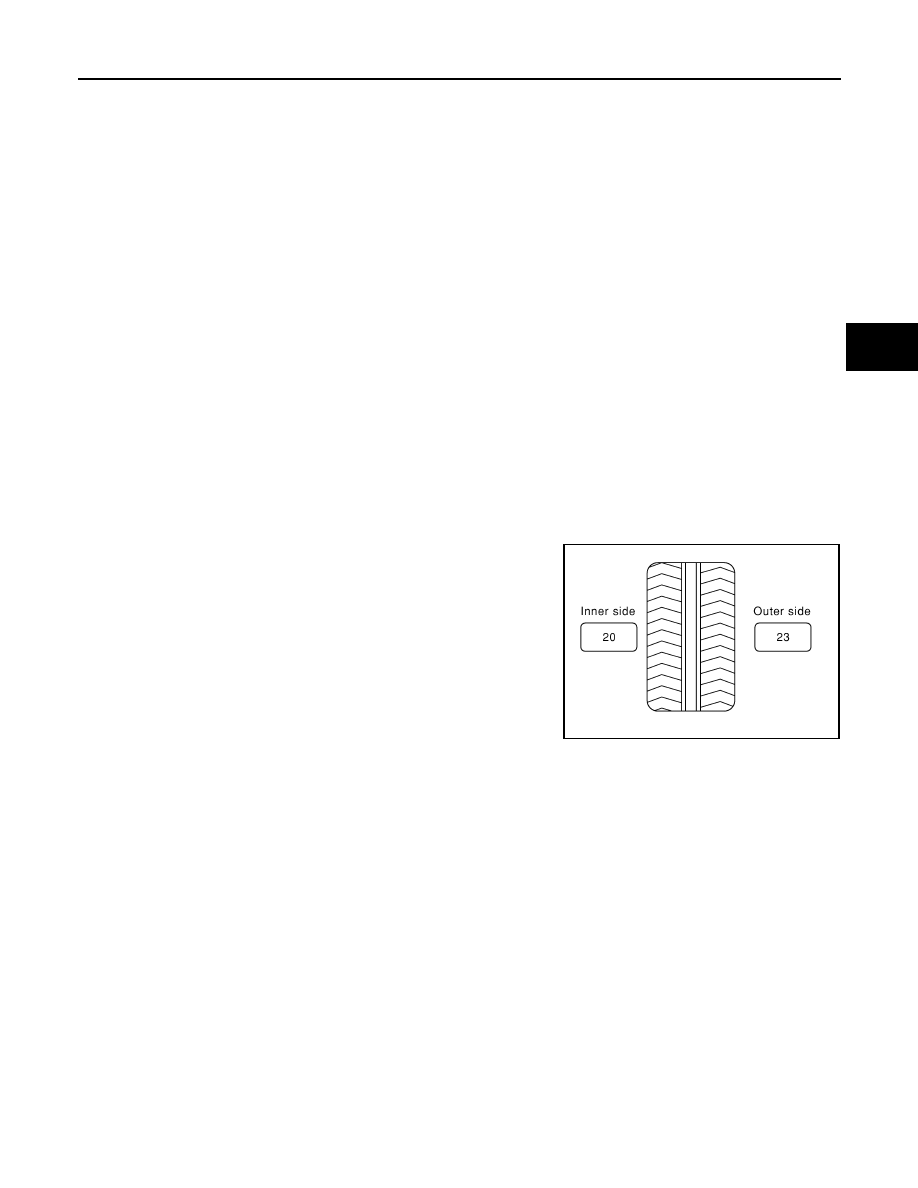

When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer

unbalance value by 5/3 to determine balance weight that should be used. Select the outer balance weight

with a value closest to the calculated value above and install to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

• Never install the inner balance weight before installing the outer balance weight.

• Before installing the balance weight, always to clean the mating surface of the road wheel.

a.

Indicated unbalance value

×

5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz)

×

5/3 = 38.33 g (1.35 oz)

⇒

37.5 g (1.32 oz) bal-

ance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

36.2

⇒

35 g (1.23 oz)

36.3

⇒

37.5 g (1.32 oz)

b.

Installed balance weight in the position.

SMA054D