Content .. 1842 1843 1844 1845 ..

Infiniti FX35, FX50 (S51). Manual - part 1844

TRANSMISSION ASSEMBLY

TM-183

< UNIT REMOVAL AND INSTALLATION >

[7AT: RE7R01A (VQ35HR)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

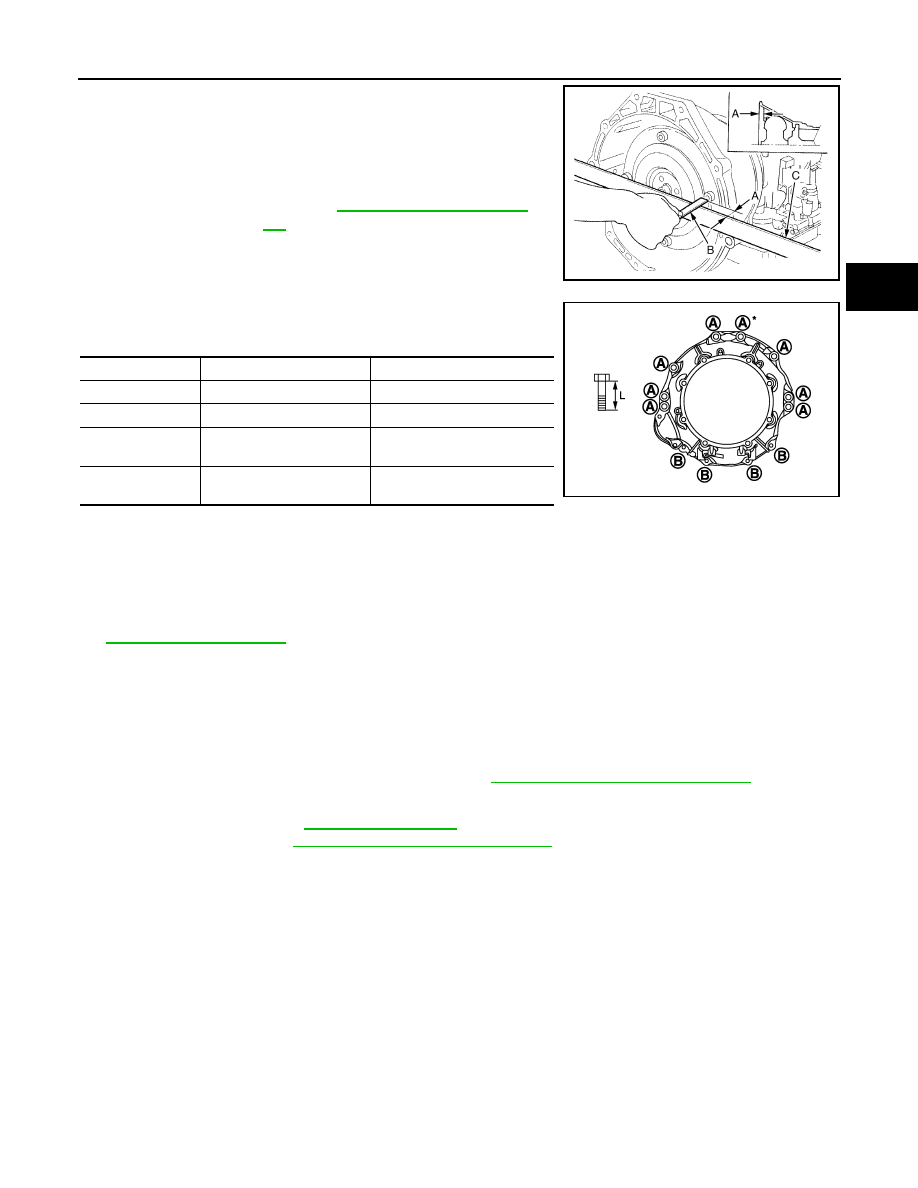

• When installing A/T assembly to the engine, be sure to check

dimension “A” to ensure it is within the reference value limit.

• When installing A/T assembly to the engine, attach the fixing bolts

in accordance with the following standard.

*: Tightening the bolt with bracket.

• Align the positions of tightening bolts for drive plate with those of the torque converter, and temporarily

tighten the bolts. Then, tighten the bolts with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the tightening bolts for the torque converter after fixing the crankshaft pulley

bolts, be sure to confirm the tightening torque of the crankshaft pulley mounting bolts. Refer to

.

• Rotate crankshaft several turns and check to be sure that A/T rotates freely without binding after

converter is installed to drive plate.

2WD : Inspection and Adjustment

INFOID:0000000005250174

INSPECTION AFTER INSTALLATION

• Check A/T fluid leakage.

• Check A/T position after adjusting A/T positions. Refer to

TM-167, "Inspection and Adjustment"

ADJUSTMENT AFTER INSTALLATION

• Adjust A/T fluid level. Refer to

• Adjust A/T position. Refer to

TM-167, "Inspection and Adjustment"

AWD

B

: Scale

C

: Straightedge

Dimension “A”

: Refer to

JPDIA0042ZZ

Bolt symbol

A

B

Insertion direction

A/T assembly to engine

Engine to A/T assembly

Number of bolts

8

4

Bolt length “L”

mm (in)

65 (2.56)

35 (1.38)

Tightening torque

N·m (kg-m, ft-lb)

75 (7.7, 55)

46.6 (4.8, 34)

JPDIA0979ZZ