Content .. 1841 1842 1843 1844 ..

Infiniti FX35, FX50 (S51). Manual - part 1843

FLUID COOLER SYSTEM

TM-179

< REMOVAL AND INSTALLATION >

[7AT: RE7R01A (VQ35HR)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

6.

Disconnect heated oxygen sensor 2 connectors (A).

7.

Remove heated oxygen sensor 2 harness (B) from clips (1).

8.

Remove harness bracket (2) from A/T assembly. Refer to

9.

Remove propeller shaft assembly (rear). Refer to

10. Remove propeller shaft assembly (front). Refer to

11. Lift up a transmission jack to make the gap between converter housing of A/T assembly and front suspen-

sion member.

CAUTION:

Never contact the A/T and transfer assembly with the lower lever of A/T shift selector when lifting

up a transmission jack.

12. Remove A/T fluid cooler tubes from A/T assembly and engine.

13. Plug up opening such as the A/T fluid cooler tube hole.

14. Remove clips and brackets.

15. Remove A/T fluid cooler tubes from the vehicle.

CAUTION:

Be careful not to bend A/T fluid cooler tubes.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never reuse copper washer.

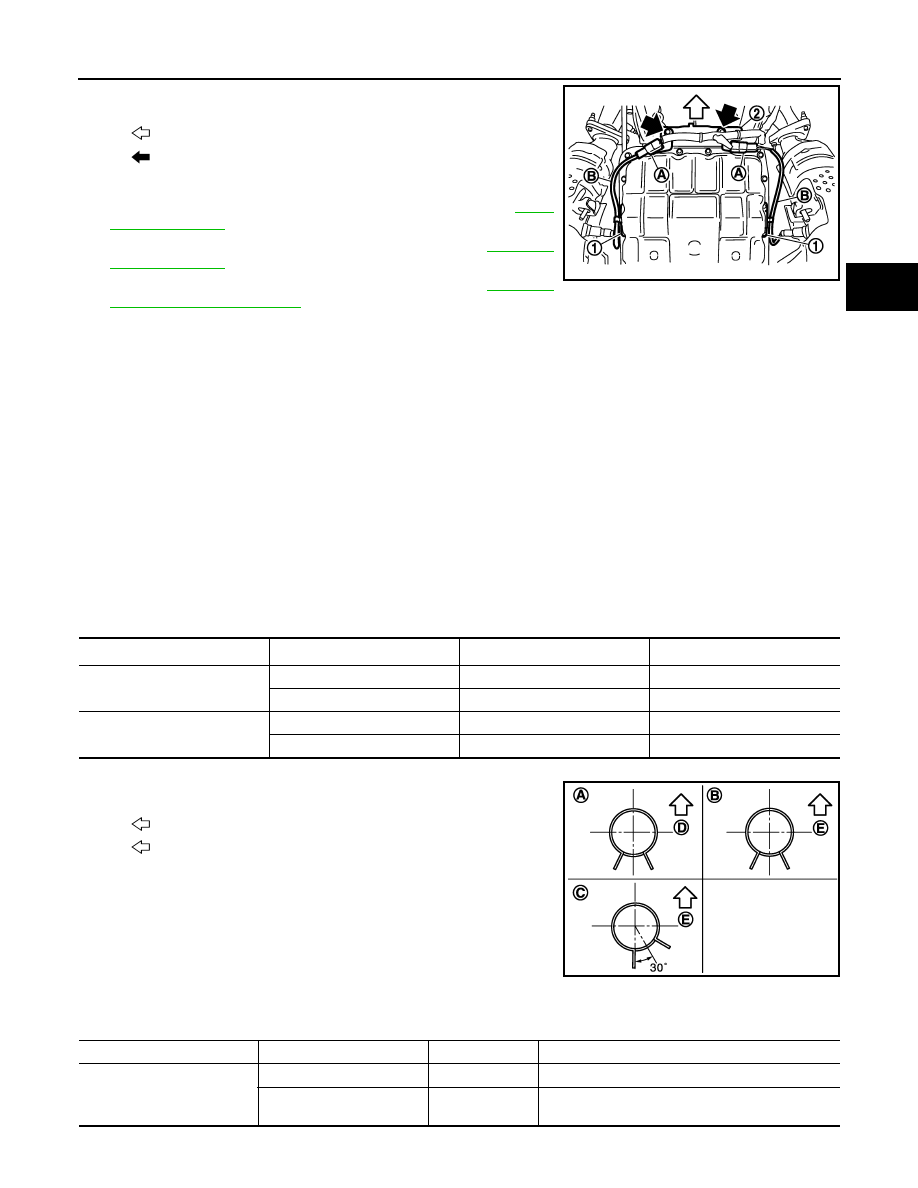

• Refer to the following when installing A/T fluid cooler hoses.

*: Refer to the illustrations for the specific position each hose clamp tab.

- The illustrations indicate the view from the hose ends.

- When installing hose clamps center line of each hose clamp tab

should be positioned as shown in the figure.

- Insert A/T fluid cooler hoses according to dimension “L” described below.

: Vehicle front

: Bolt

SCIA8269E

Hose name

Hose end

Paint mark

Position of hose clamp

*

A/T fluid cooler hose A

Radiator assembly side

Facing backward

A

A/T fluid cooler tube side

Facing downward

B

A/T fluid cooler hose B

Radiator assembly side

Facing downward

C

A/T fluid cooler tube side

Facing downward

B

D

: Vehicle front

E

: Vehicle upper

JSDIA0795ZZ

(1)

(2)

Tube type

Dimension “L”

A/T fluid cooler hose A

Radiator assembly side

A

End reaches the radius curve end.

A/T fluid cooler tube side

B

30 mm (1.18 in) [End reaches the 2-stage bulge

(D).]