Content .. 1757 1758 1759 1760 ..

Infiniti FX35, FX50 (S51). Manual - part 1759

ST-28

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

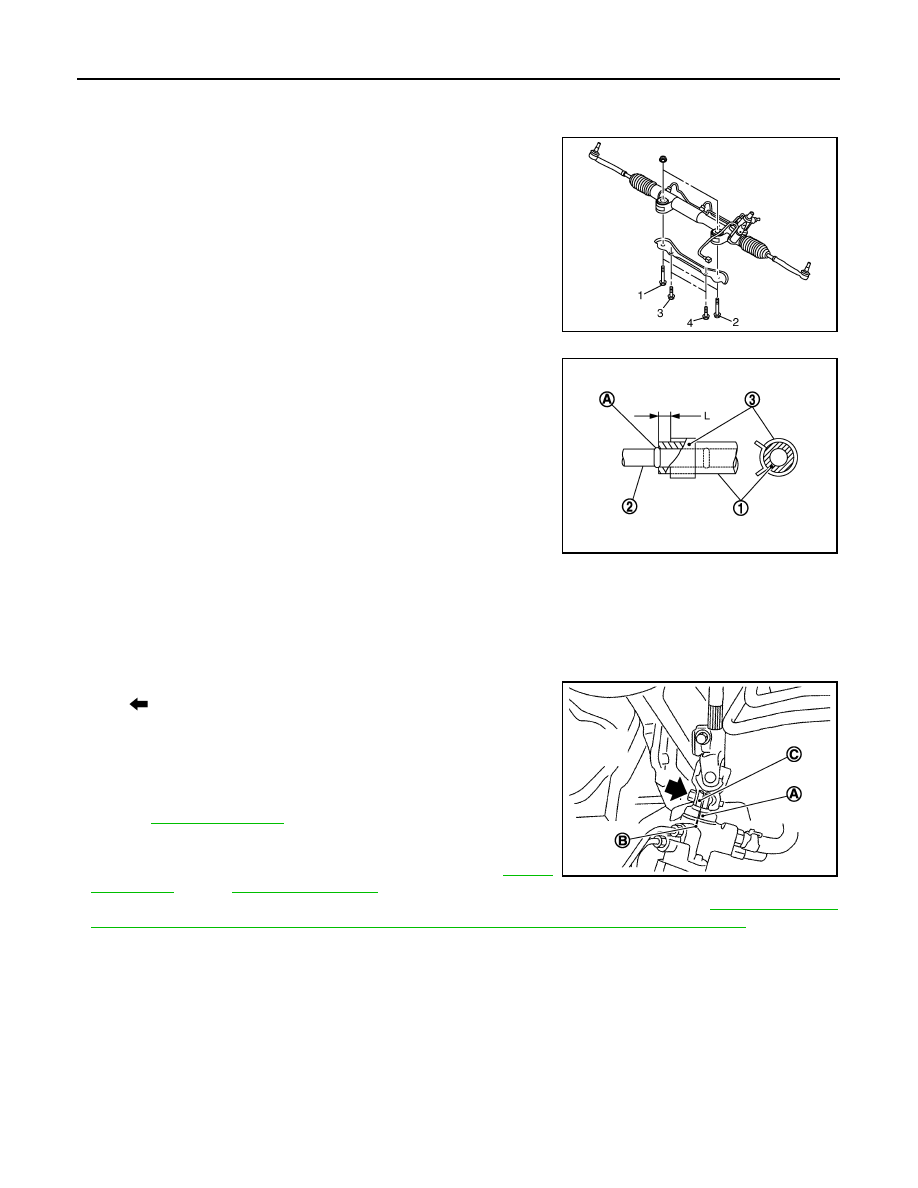

• Tighten the mounting bolts in the order shown in the figure when

installing the steering gear assembly.

CAUTION:

Never reuse the steering gear assembly mounting nut.

• When installing suction hoses (1), refer to the figure.

CAUTION:

• Never apply fluid to the hose (1) and tube (2).

• Insert hose securely until it contacts spool (A) of tube.

• Leave clearance (L) when installing clamp (3).

• When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub assembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap

projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

• After installation, bleed air from the steering hydraulic system.

.

• Perform final tightening of nuts and bolts on each part under

unladen conditions with tires on level ground when removing steer-

ing gear assembly. Check wheel alignment. Refer to

(AWD).

• Adjust neutral position of steering angle sensor after checking wheel alignment. Refer to

MENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement"

Disassembly and Assembly

INFOID:0000000005235284

DISASSEMBLY

1.

Remove low pressure piping.

CAUTION:

• Disassemble and assemble steering gear assembly by fixing the mounting area with a vise using

copper plates.

• Clean steering gear assembly with kerosene before disassembling. Be careful to avoid splash-

ing or applying any kerosene over connector of discharge port or return port.

2.

Remove cylinder tubes from gear housing assembly.

Temporary tightening: 1

⇒

2

⇒

3

⇒

4

Final tightening: 1

⇒

2

⇒

3

⇒

4

JSGIA0112ZZ

Standard

L

: 3 – 8 mm (0.12 – 0.31 in)

JSGIA0118ZZ

: Bolt

JSGIA0111ZZ